Sub-rail bamboo and wood composite heightening railroad tie plate for concrete sleeper

A bamboo-wood composite and concrete technology, which is applied in the direction of rails, fixed rails, and wood-layered products, can solve the problems of double-sided gluing or bed gluing, low labor efficiency, and inability to satisfy problems at the same time. The effect of low production cost, reducing the amount of glue applied, and saving manual labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

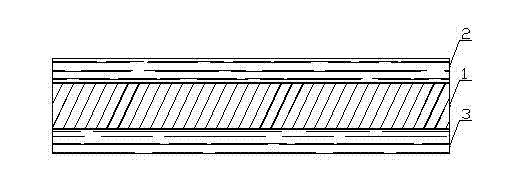

[0012] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. Concrete sleepers use bamboo and wood composite height-adjusting pads under rails, which include a core layer 1, an upper bamboo curtain surface layer 2 and a lower bamboo curtain surface layer 3, and the two sides of the core layer 1 are glued with the upper bamboo curtain surface layer 2 and the lower bamboo curtain surface layer 3 respectively.

[0013] The core layer 1 described in this embodiment is made of veneer material with high density. Fraxinus mandshurica, larch or birch has the characteristics of hard wood, small deformation, small compression ratio, and easy gluing, which can ensure that the technical specifications are consistent with the backing plate. Density requirement, be used as the material of production core layer 1; Described upper bamboo screen surface layer 2 and lower bamboo screen surface layer 3 select the bamboo yellow strips...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the bamboo curtain surface layer 2 and the lower bamboo curtain surface layer 3 are made of bamboo strips, and the thickness of the bamboo strips is 0.5mm, the allowable tolerance range is ±0.1mm, bamboo strips are used in the horizontal direction, cotton threads are used in the vertical direction, and the interval between two adjacent cotton threads is 100-200mm.

specific Embodiment approach 3

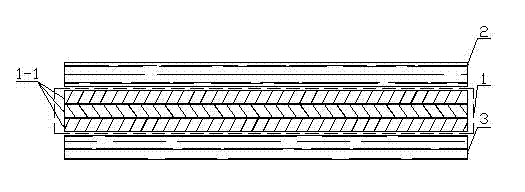

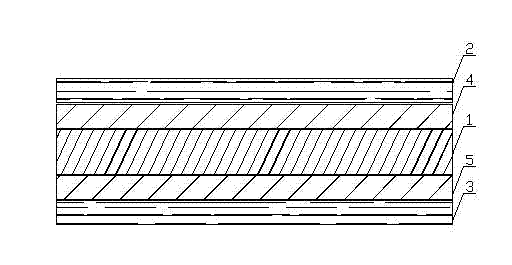

[0017] Specific implementation mode three: the following combination figure 2 This embodiment will be specifically described. The difference between this embodiment and the second embodiment is that: the height-adjusting backing plate is based on the required thickness of the backing plate, and the core layer 1 is assembled from N layers of high-density wooden veneers 1-1. glued together, where N is 1 or 3.

[0018] In this embodiment, when the thickness of the height-adjusting backing plate is 2 to 3 mm, the upper bamboo curtain surface layer 2 and the lower bamboo curtain surface layer 3 are made of bamboo-yellow bamboo strips, and the number of layers of the core layer 1 is Odd-numbered layers, based on the thickness requirements of the heightening backing plate, the number of layers of the core layer 1 is 1 layer or 3 layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com