Winding rotor motor for preventing accumulated dust adsorption and creepage

A wound rotor motor, anti-dust technology, used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of poor running time quality, poor application analysis, etc., to extend the cleaning cycle and reduce creepage discharge. Damage rate, improve the effect of trouble-free use time

Inactive Publication Date: 2010-08-25

SHANGHAI DIANJI UNIV +1

View PDF1 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, at present, the tolerance matching standards adopted internationally and domestically are relatively rough, and the application analysis is not detailed, which often results in poor quality of running time when the batch of products is within the tolerance range.

At present, when designing the matching standard of the motor shaft, you can refer to "GB5371-xx tolerance and calculation and selection of interference fit", but when selecting the tolerance of the bearing outer ring and the matching hole of the bearing chamber, you can only choose to refer to "GB1801" which has no calculation method -xx tolerance and fit size to 500mm hole, shaft tolerance band fit", etc., "GB / T275-xx Rolling bearing fit with shaft and housing"

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

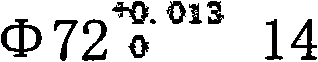

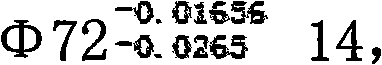

The invention discloses a winding rotor motor for preventing accumulated dust adsorption and creepage. A stator and a rotor of the motor are made of a silicon steel sheet rolled by a high-performance energy-saving process; the electromagnetic design is performed in a standardized form according to the requirement; the motor driving and a collecting ring are treated by isolation; a part with a creepage preventing standard distance is needed to be insulated in a collecting ring area; and the surface of the part is completely treated by using nano particle insulated paint to form an insulated surface low-tension area which has self-clean performance and is not easy to accumulate and adsorb dust. With the fit of a motor end cover bearing chamber hole and a bearing outer ring, and referencing to three difference states of natural assembly, normal work and special work in which different matched materials are positioned as well as a clearance variable difference generated by an expansion coefficient, a normal work state can be selected as a matching reference and a design processing deviation can be determined by replacing the traditional selection mode by a computing mode. An O-shaped ring is additionally assembled to adjust when the expansion variable difference is larger. The invention always ensures that the bearing is operated in the state of oil froth, thereby achieving the aim of improving the non-fault operating time and the quality of the motor.

Description

Technical field: The invention relates to an anti-dust absorption creepage winding rotor motor in the electromechanical field. Background technique: Wound rotor motors are extremely widely used in electric motors. Among them, there are mainly three-phase motors for lifting and metallurgical motors with better starting and torque performance; adjustable speed motors and generators; various electric tools; and various wound rotors using similar collector rings Synchronous and asynchronous motors. The market demand and mass production of wound rotor motors are relatively less than those of cast aluminum rotor motors. Therefore, in today's rapidly changing social needs, high requirements for environmental protection and energy saving, continuous product upgrades, and product application specialization, the product conversion speed is often slower than that of cast aluminum rotor motors. At the same time, the electromagnetic design of the motor is very mature, and the requirem...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02K15/00H02K5/16H02K13/00

Inventor 汤学华陈丹叶礼明葛良璞

Owner SHANGHAI DIANJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com