Feeding device of open-type injection molding machine

A technology of feeding device and injection molding machine, applied in the field of injection molding machine, can solve the problems of large occupied space, complex structure, long barrel distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

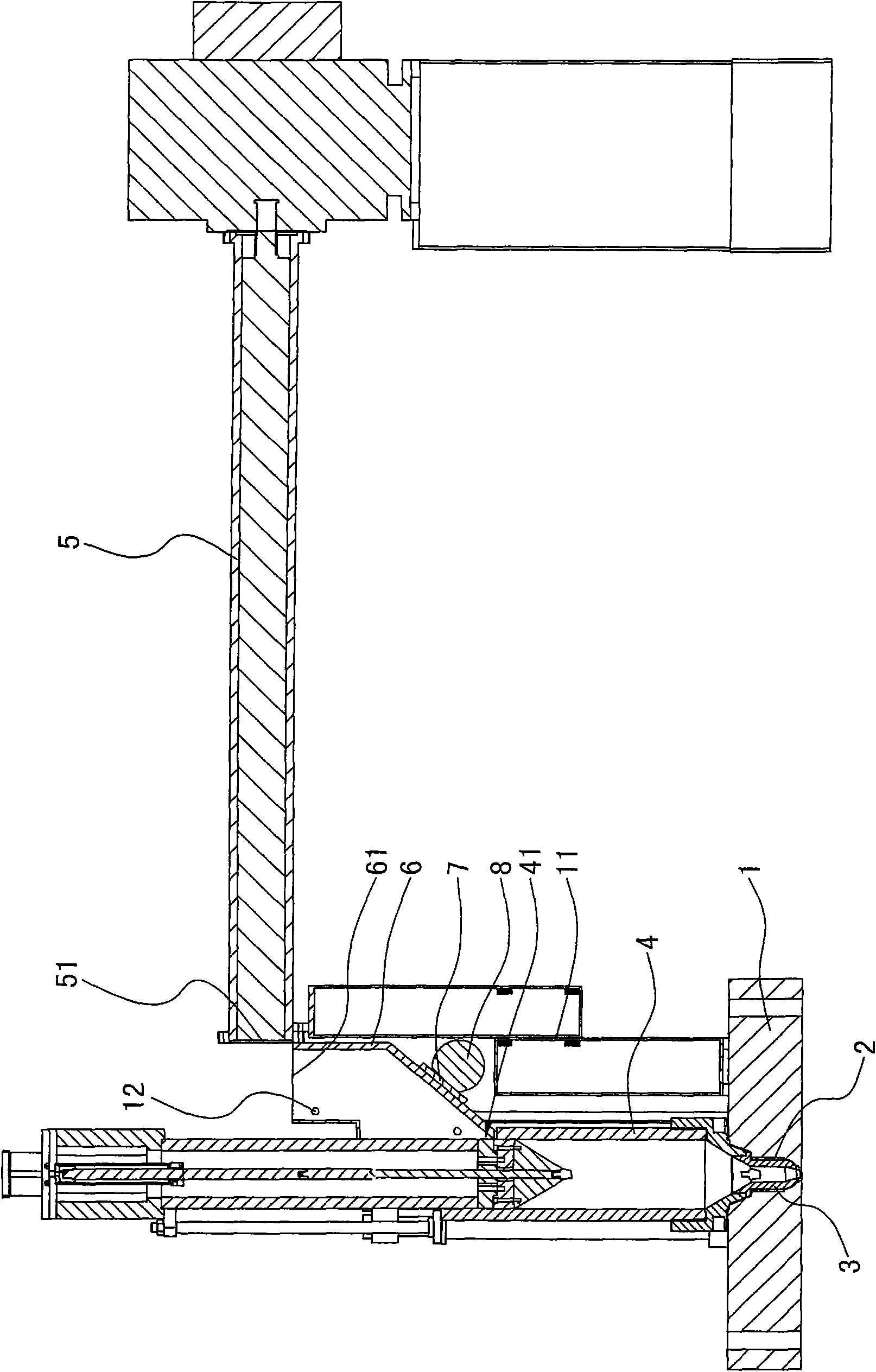

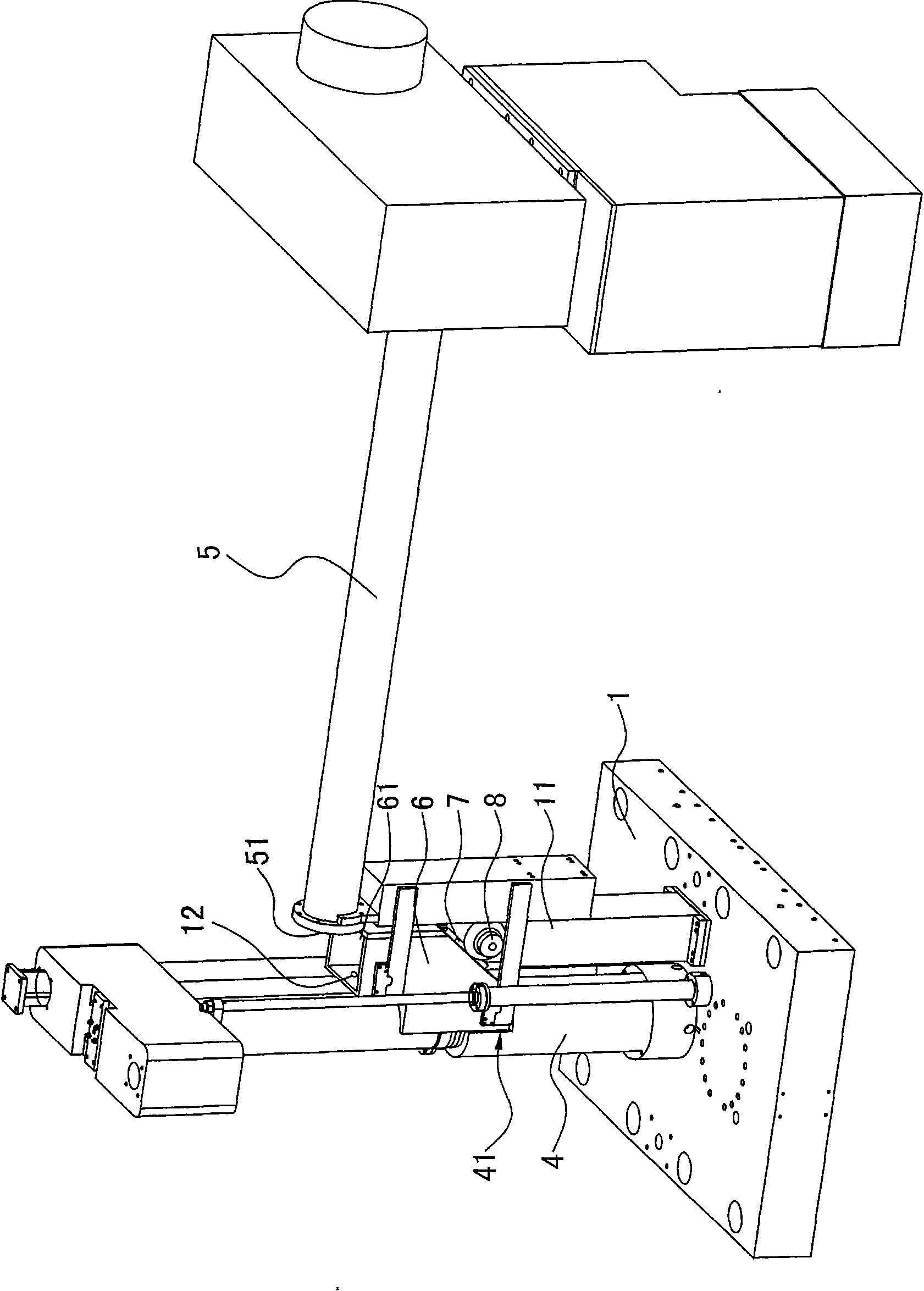

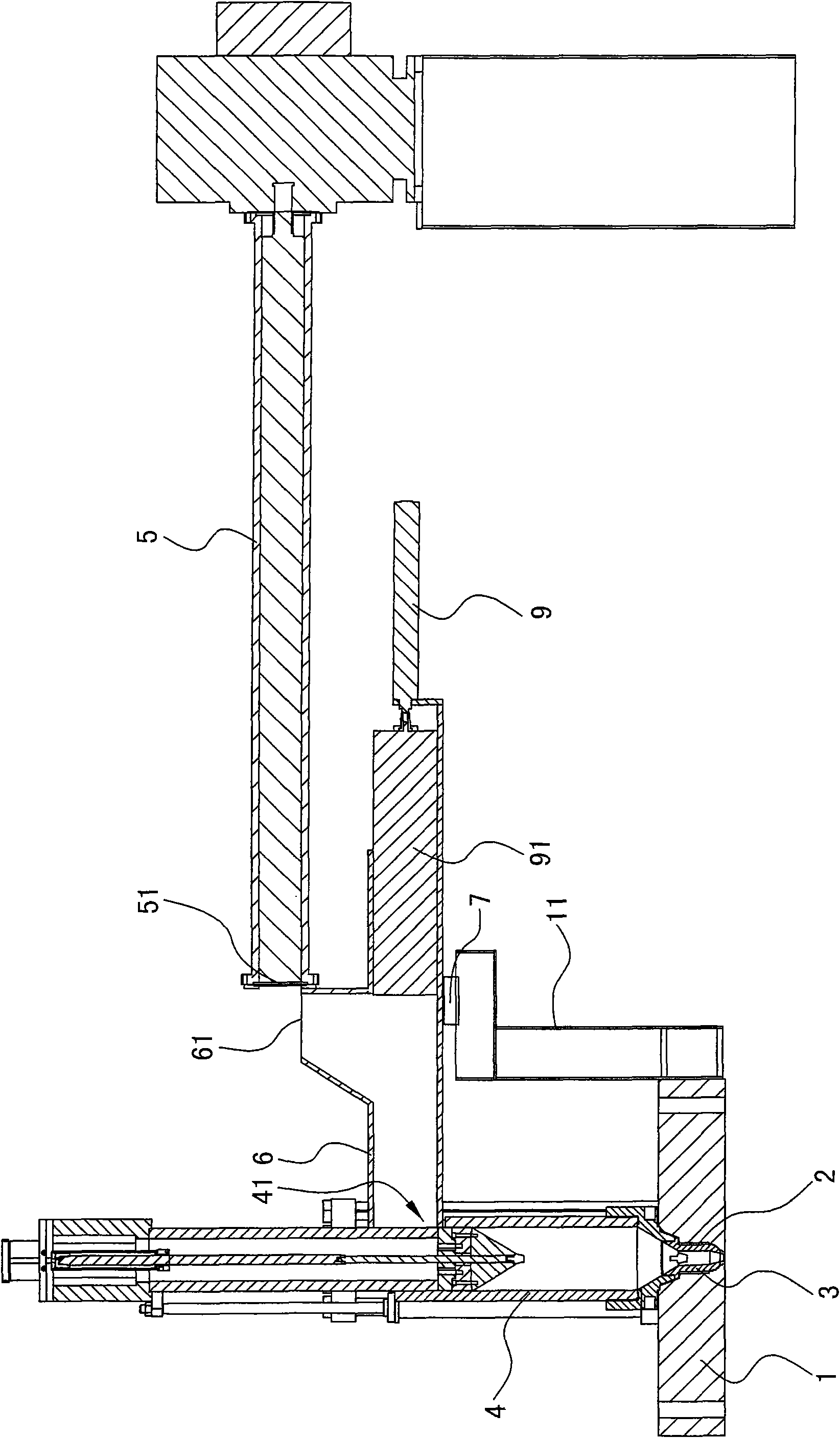

[0011] The present invention relates to an open type injection molding machine feeding device, such as Figure 1-Figure 4 As shown, it includes a template 1 and an injection molding device. The template can be installed up and down or left and right. The template is installed with a mold. A feed inlet 2 is formed in the template. The head 3 is connected to the storage cylinder 4, and the pre-push device and the injection molding device are installed in the storage cylinder 4. The storage cylinder 4 is connected to the material barrel 5. It is characterized in that the mouth of the storage cylinder 4 is formed with an opening 41, and the opening 41 is connected. Feed hopper 6, the inlet 61 of feed hopper 6 is in contact with the outlet 51 of barrel 5, electronic scale 7 is installed on the bottom surface of feed hopper 6 or photoelectric switch 12 is installed on the inner wall, and feed hopper 6 has blanking device. Be shaped on opening 41 (open type) at the mouth portion of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com