Hot wire fixing structures for transient hot wire method measurement

A technology of fixed structure and hot wire method, which is applied in the direction of material thermal conductivity, etc., can solve the problems of uncommercialization and easy breakage of hot wire, and achieve the effect of not being afraid of vibration and shaking, easy welding of hot wire, and stable structure of hot wire fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention successfully overcomes two factors affecting the reliability of the hot wire structure.

[0026] (1) Use a metal wire or metal rod made of the same material as the hot wire (or very close to the linear expansion coefficient) as the bracket, straighten the hot wire and weld it to the bracket with a certain tension, which can ensure that the hot wire remains tensioned at any temperature state. This method does not need to hang heavy objects or add springs, which greatly enhances the reliability of the hot wire.

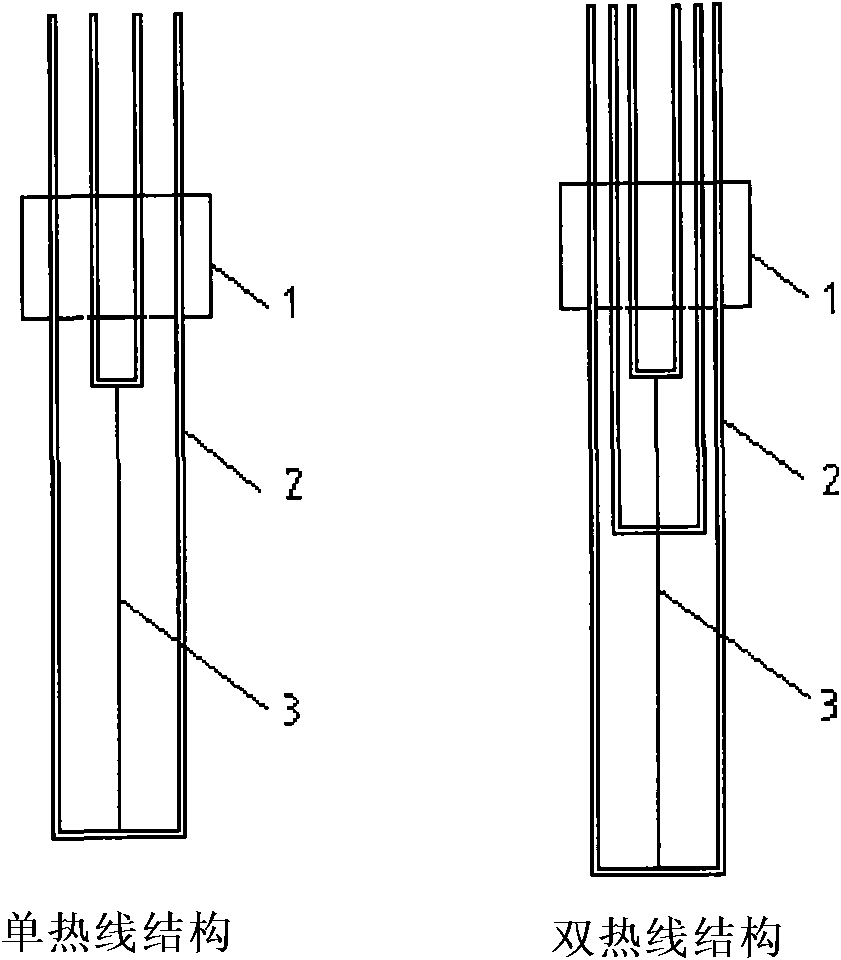

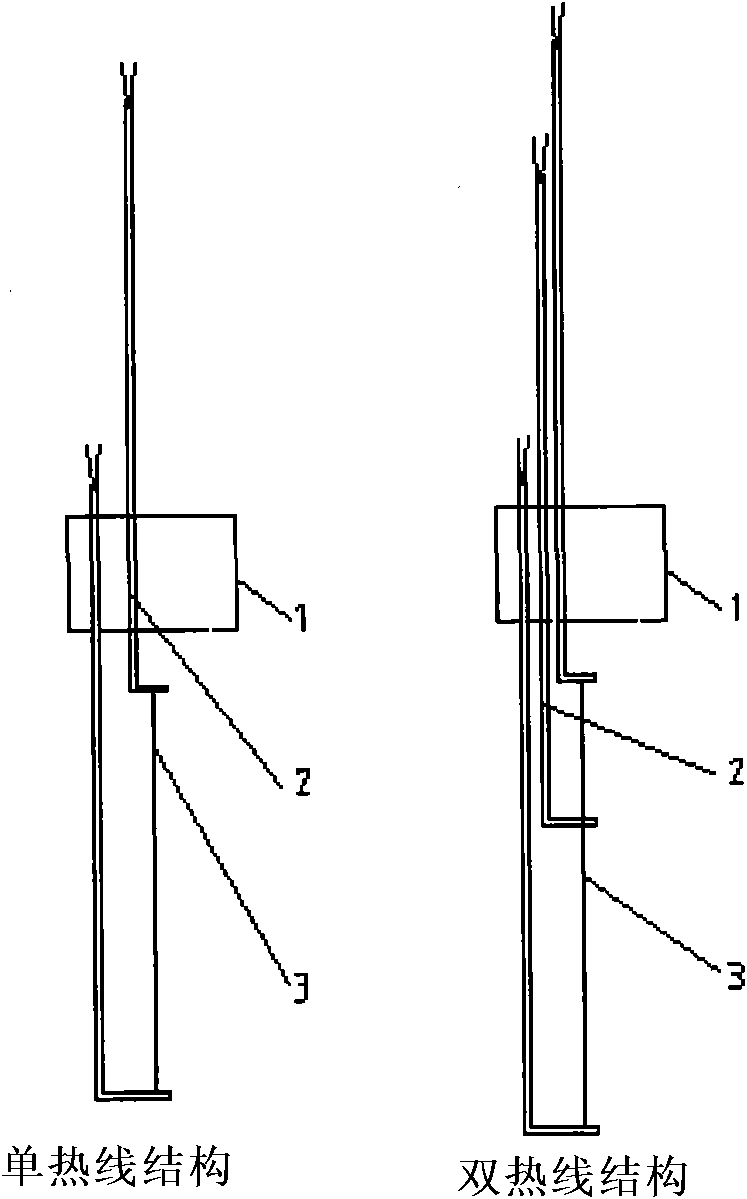

[0027] (2) Weld the hot wire directly on the wire support, so that only 2 solder points are needed for a single hot wire, and only 3 solder points are needed for a double hot wire, and the welding is also very easy. In the structure of the present invention, only 6 wires need to be drawn out from the dual heating wires, which simplifies the structure of the dual heating wires.

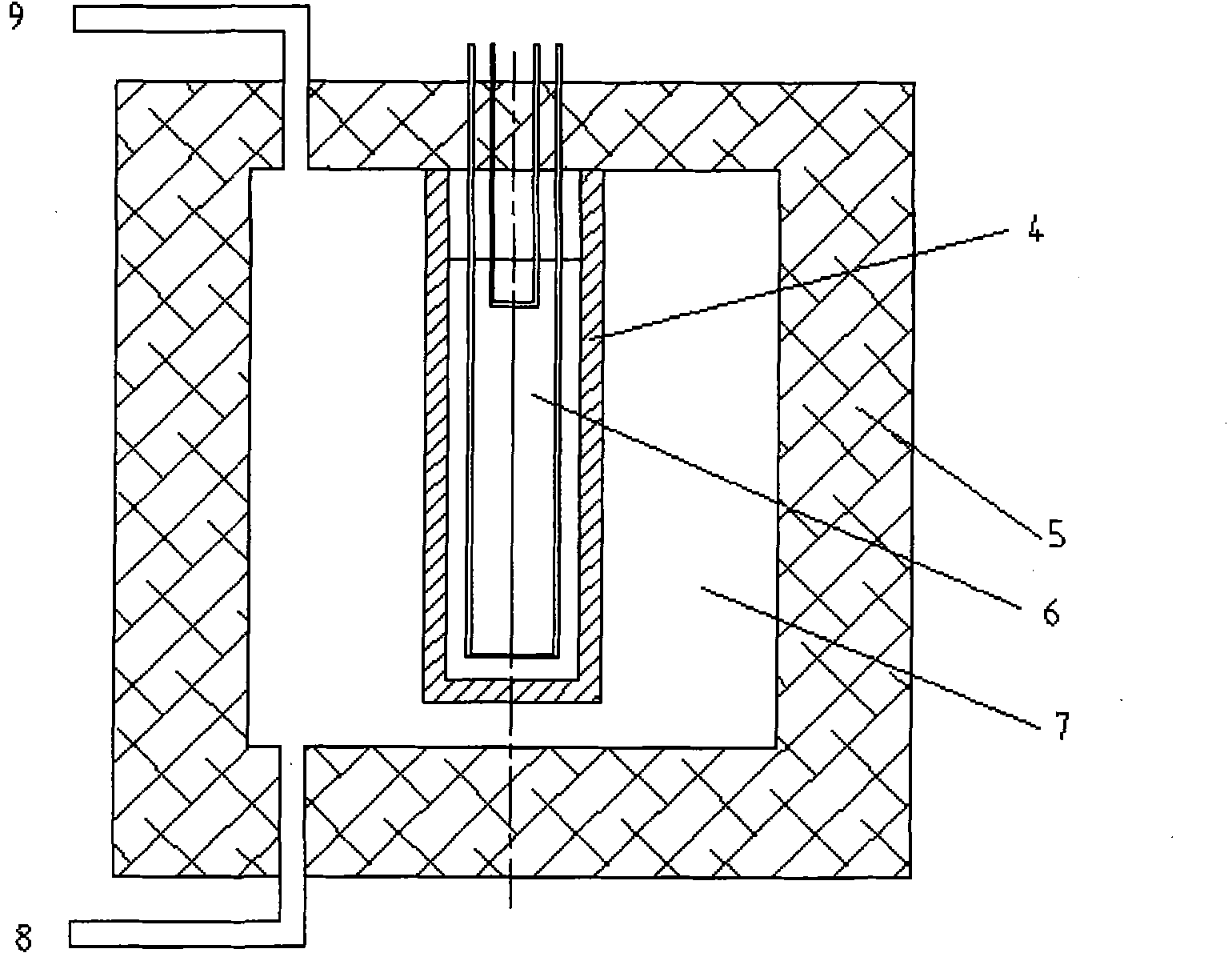

[0028] Figure 1~2 It is three kinds of hot wire fixing structure di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com