Method and system for driving electromagnetic valve of diesel engine

A solenoid valve drive, diesel engine technology, applied in the direction of machines/engines, electrical control, mechanical equipment, etc., can solve the problems of inability to realize the "partially open" state, inability to realize fuel injection, etc., and achieve good inheritance and wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

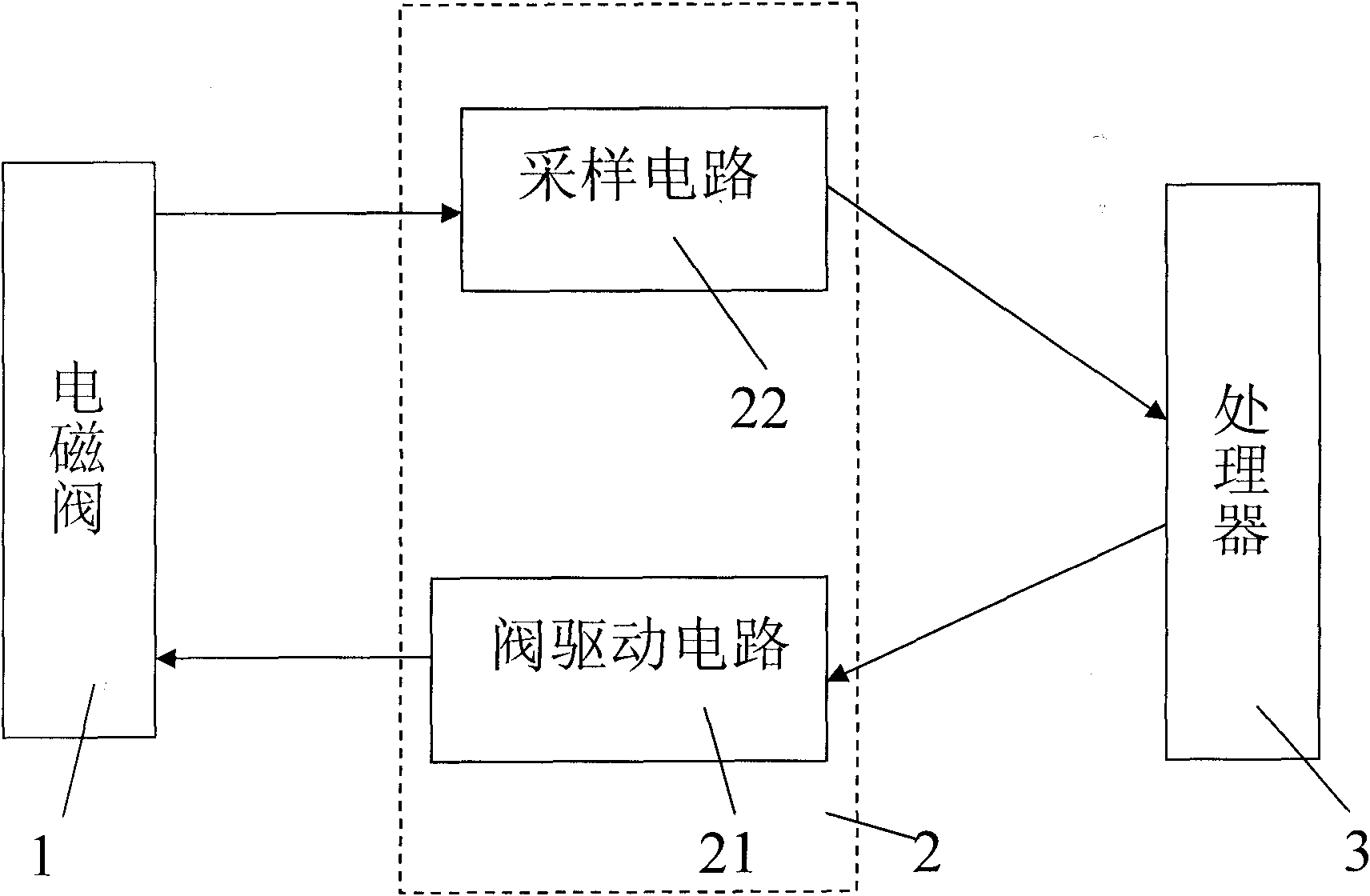

[0023] Such as figure 1 As shown, the driving system of the present invention includes a solenoid valve 1 , a sampling and driving unit 2 and a processor 3 . Solenoid valve 1 is the moving part in the fuel injection system, it is the injector solenoid valve in the common rail fuel injection system, and it is the high pressure pump solenoid valve in the unit pump fuel injection system. The sampling and driving unit 2 includes a sampling circuit 21 and a valve driving circuit 22 . The sampling circuit 21 samples the driving current of the solenoid valve 1 and sends the collected actual driving current to the processor 3 . The valve driving circuit 22 adjusts the driving current of the solenoid valve 1 according to the control signal of the processor 3 .

[0024] What the processor 3 of the present invention adopts is the FreeScale MC9S12XEP100 type sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com