Assistant cooling structure of water-cooled platform

An auxiliary cooling and water cooling technology, which is applied in the testing of machines/structural components, measuring devices, vibration testing, etc., can solve problems such as temperature rise, and achieve the effects of increased power, easy implementation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

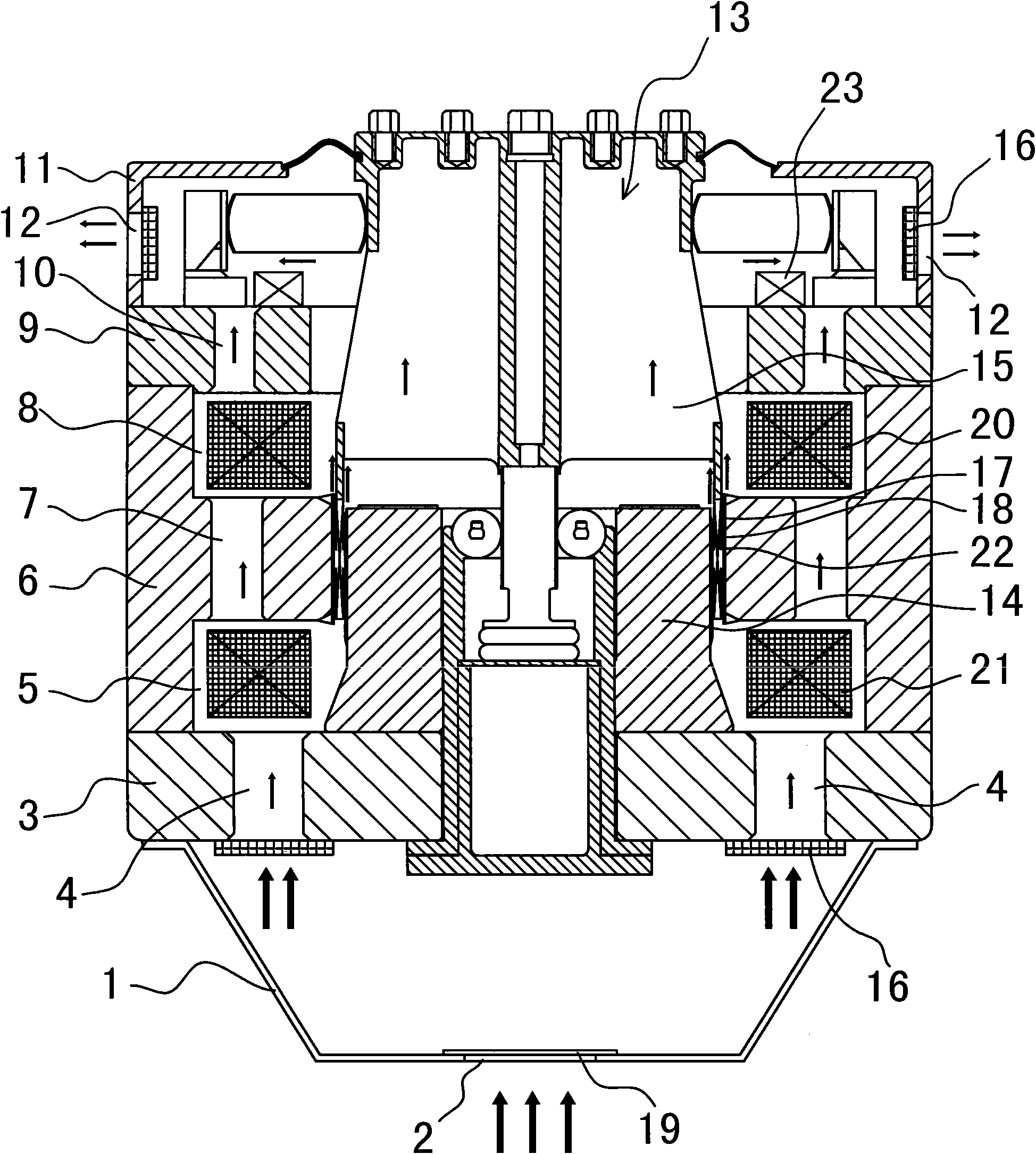

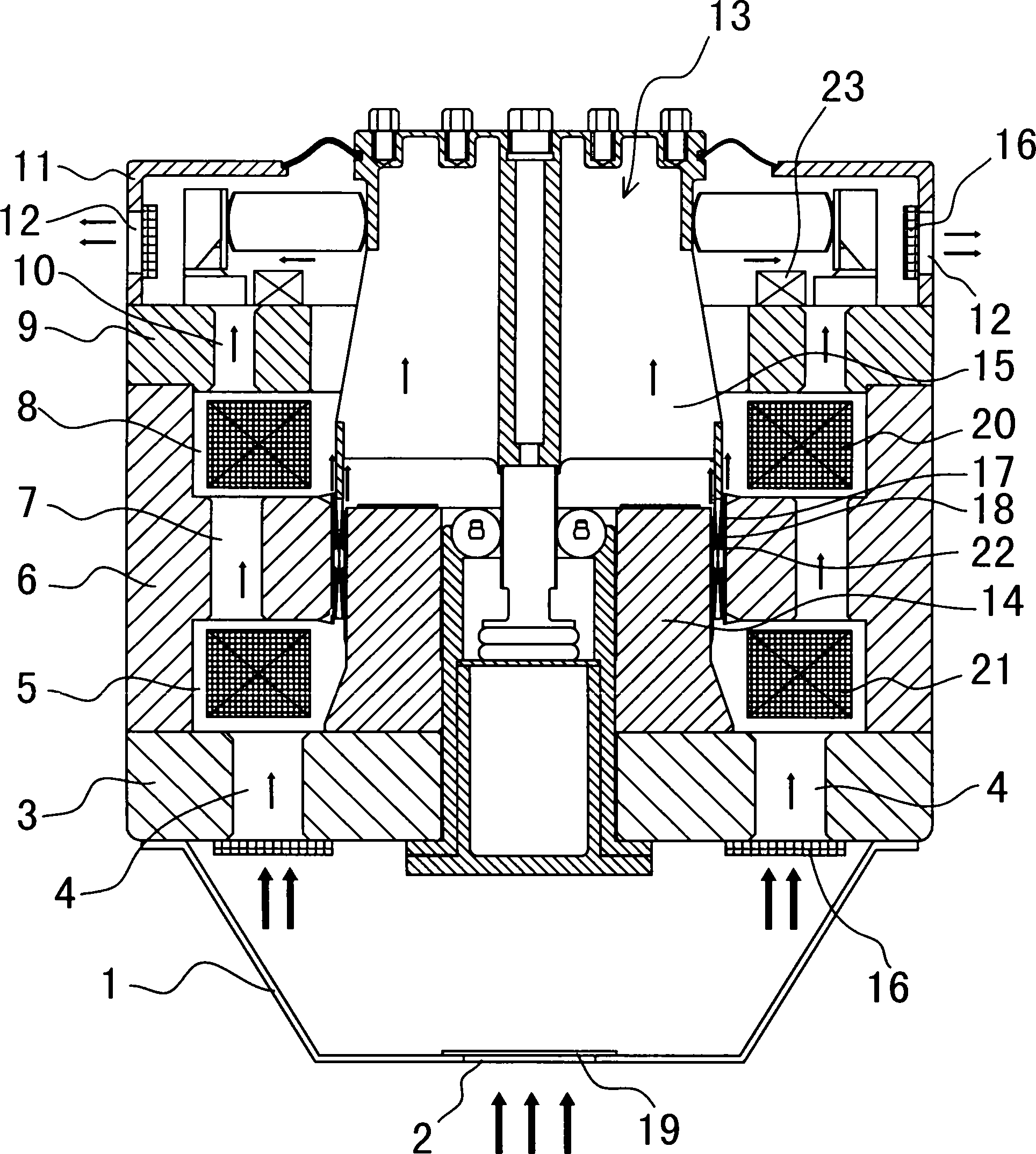

[0019] Example: see attached figure 1 Shown:

[0020] An auxiliary cooling structure for a water-cooled platform, an air inlet 2 is provided on the lower casing 1 of the water-cooled platform (specifically in the center of the bottom), and the air inlet 2 is covered with a mesh plate 19 to prevent the inhalation of debris; and On the bottom 3 of the magnetic cylinder of the water-cooled table, a plurality of first ventilation openings 4 are evenly distributed around the circumference, and these first ventilation openings 4 communicate with the inner cavity of the lower casing 1 and the placement space 5 of the lower excitation coil. On the magnetic cylinder ring 6 of the water-cooled platform, a plurality of second vents 7 are evenly distributed around the circumference, and these second vents 7 communicate with the placement space 5 of the lower excitation coil and the placement space 8 of the upper excitation coil; A plurality of third vents 10 are evenly distributed around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com