Austenitic stainless steel

An austenitic and stainless steel technology, which is applied in the field of high-strength austenitic stainless steel and heat-resistant steel, can solve problems such as cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

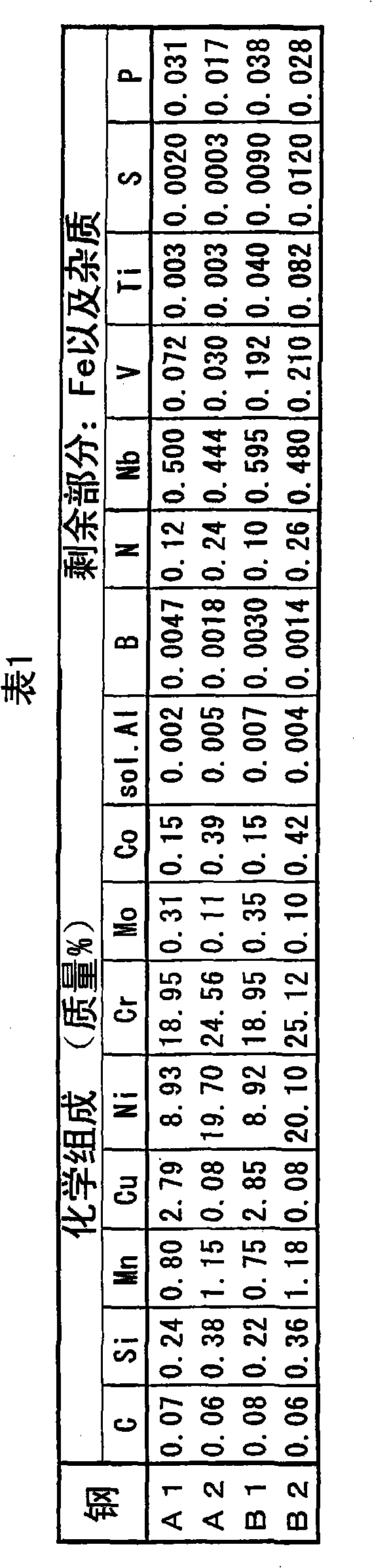

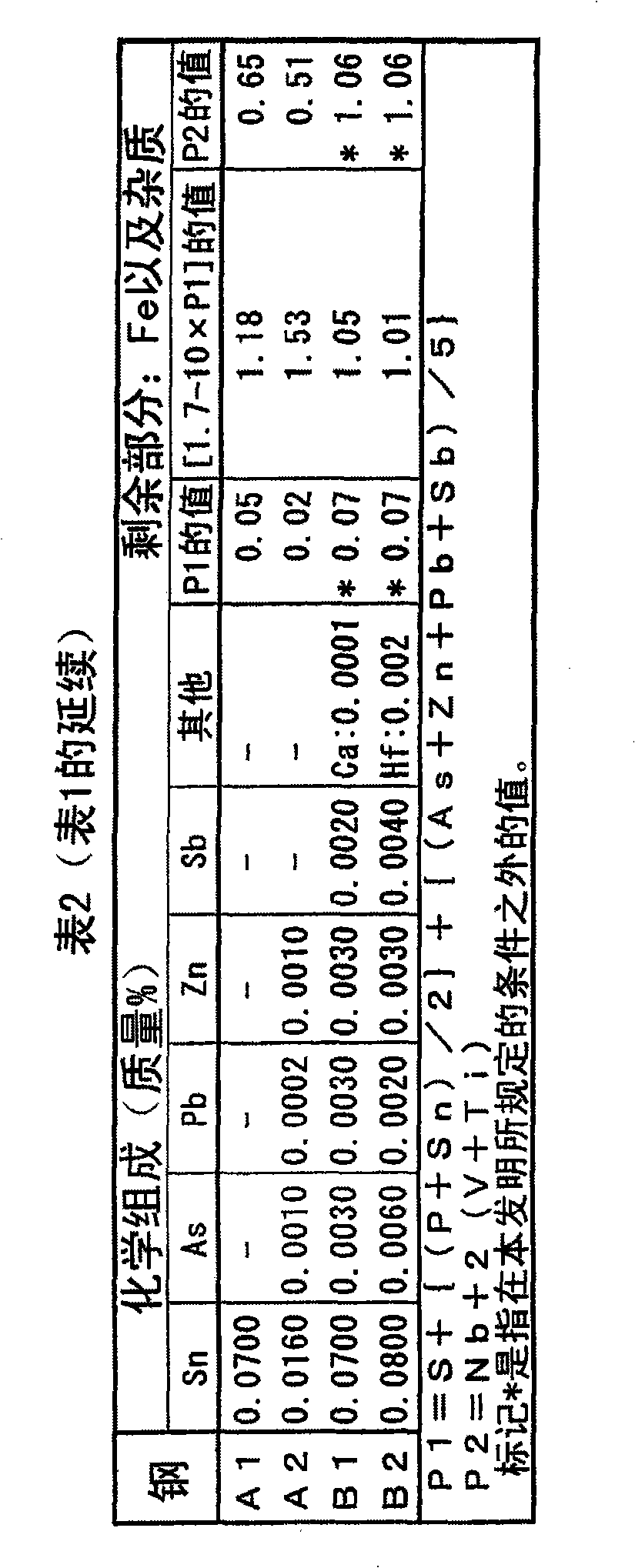

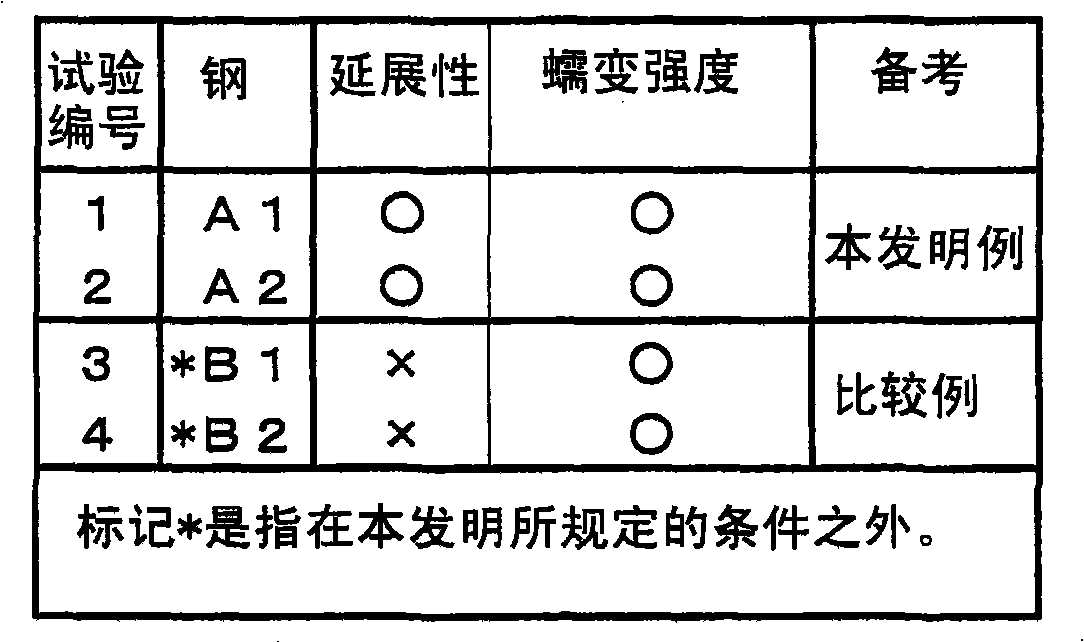

[0153] The austenitic stainless steels having the chemical compositions shown in Table 1 and Table 2, namely steel A1, steel A2, steel B1, and steel B2 were melted in an electric furnace, and formed by hot forging and hot rolling. Then, it is heated to 1200°C and water-cooled heat treatment is performed, and then a steel plate with a thickness of 20 mm, a width of 50 mm, and a length of 100 mm is produced by machining.

[0154] In addition, steel A1 and steel A2 in Table 1 and Table 2 are steels whose chemical composition falls within the range specified by the present invention. On the other hand, steel B1 and steel B2 are steels of comparative examples in which the values of parameters P1 and P2 are outside the conditions specified in the present invention.

[0155]

[0156]

[0157] Then, a V-shaped groove with an angle of 30° and a weld root thickness of 1mm was processed along the length direction of the steel plate of steel A1, steel A2, steel B1, and steel B2, and then JIS...

Embodiment 2

[0168] The austenitic stainless steels having the chemical compositions shown in Table 4 and Table 5, namely steels A3 to A13, steel B3, and steel B4 were melted in an electric furnace, and formed by hot forging and hot rolling. Then, it is heated to 1200°C and water-cooled heat treatment is performed, and then a steel plate with a thickness of 20 mm, a width of 50 mm, and a length of 100 mm is produced by machining.

[0169] In addition, the steels A3 to A13 in Tables 4 and 5 are steels with chemical compositions within the range specified by the present invention. On the other hand, steel B3 and steel B4 are steels of comparative examples in which the value of parameter P2 is outside the range specified by the present invention.

[0170]

[0171]

[0172] A sample of 12mm×12mm×100mm is selected from the central part of the steel plate with a thickness of 20mm, a width of 50mm, and a length of 100mm prepared as described above, and the sample is subjected to a HAZ simulation therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com