Helix extrusion type sludge dehydrator

A sludge dewatering machine and screw extrusion technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of clogged water outlet gap, failure to discharge in time, and reduced processing capacity, so as to solve blockage and ensure smooth water outlet Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

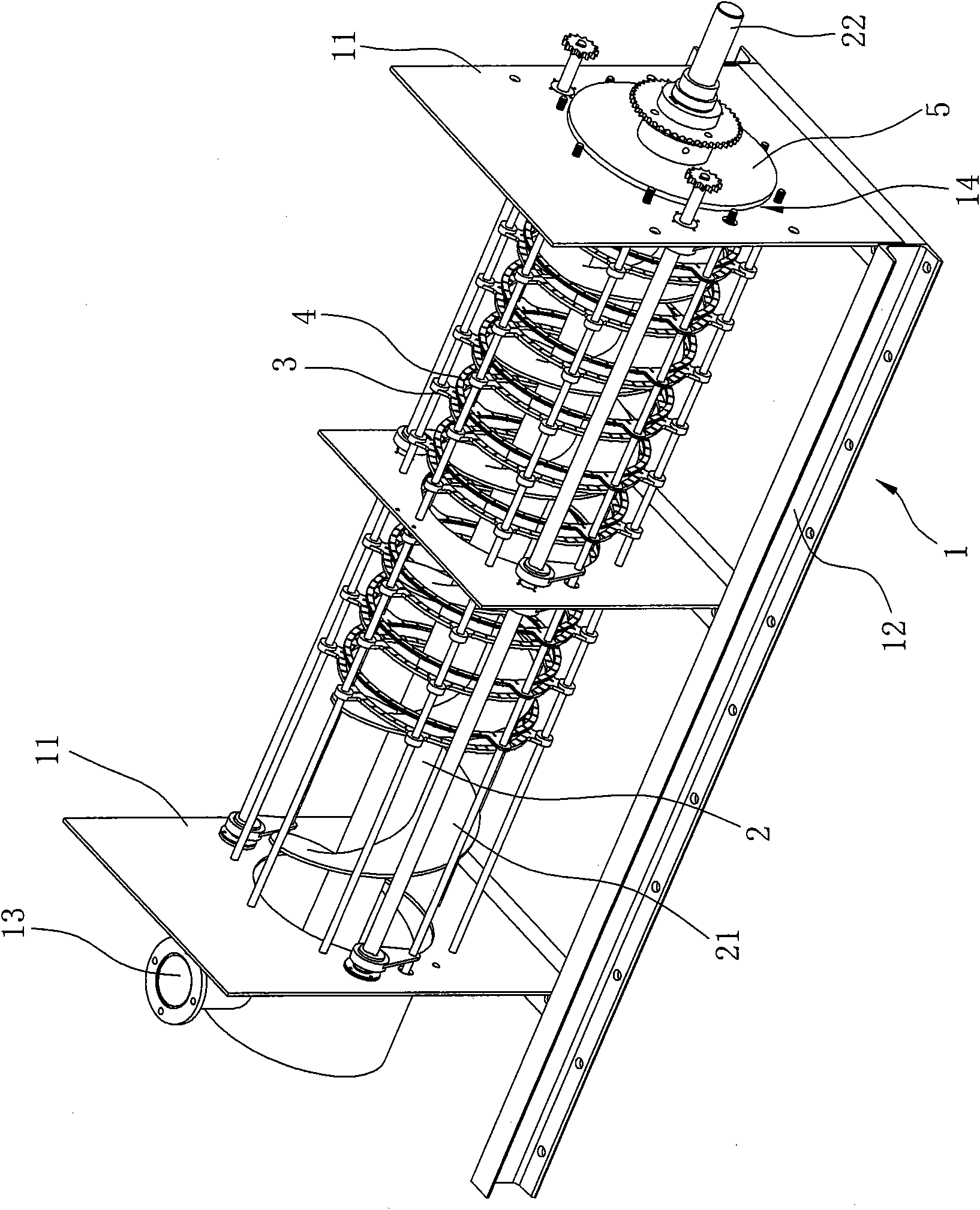

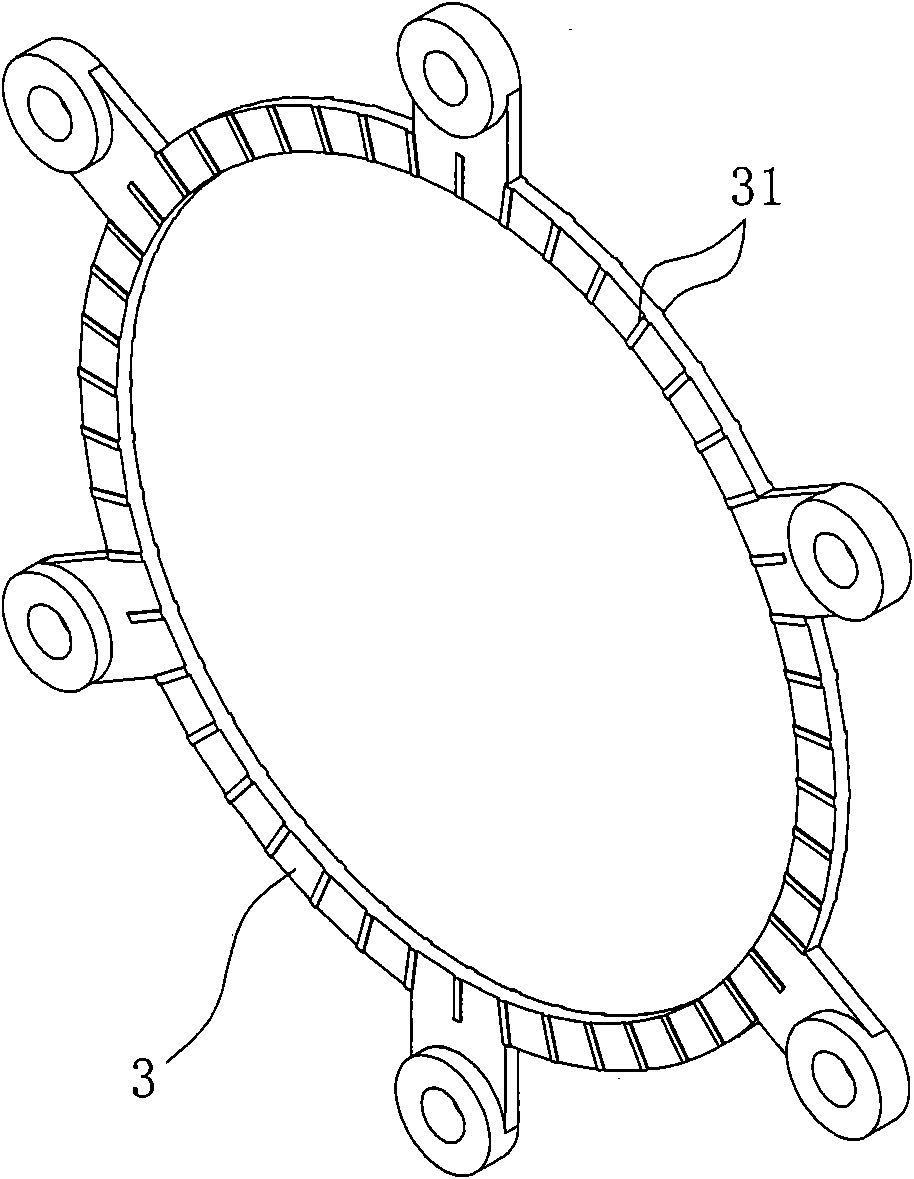

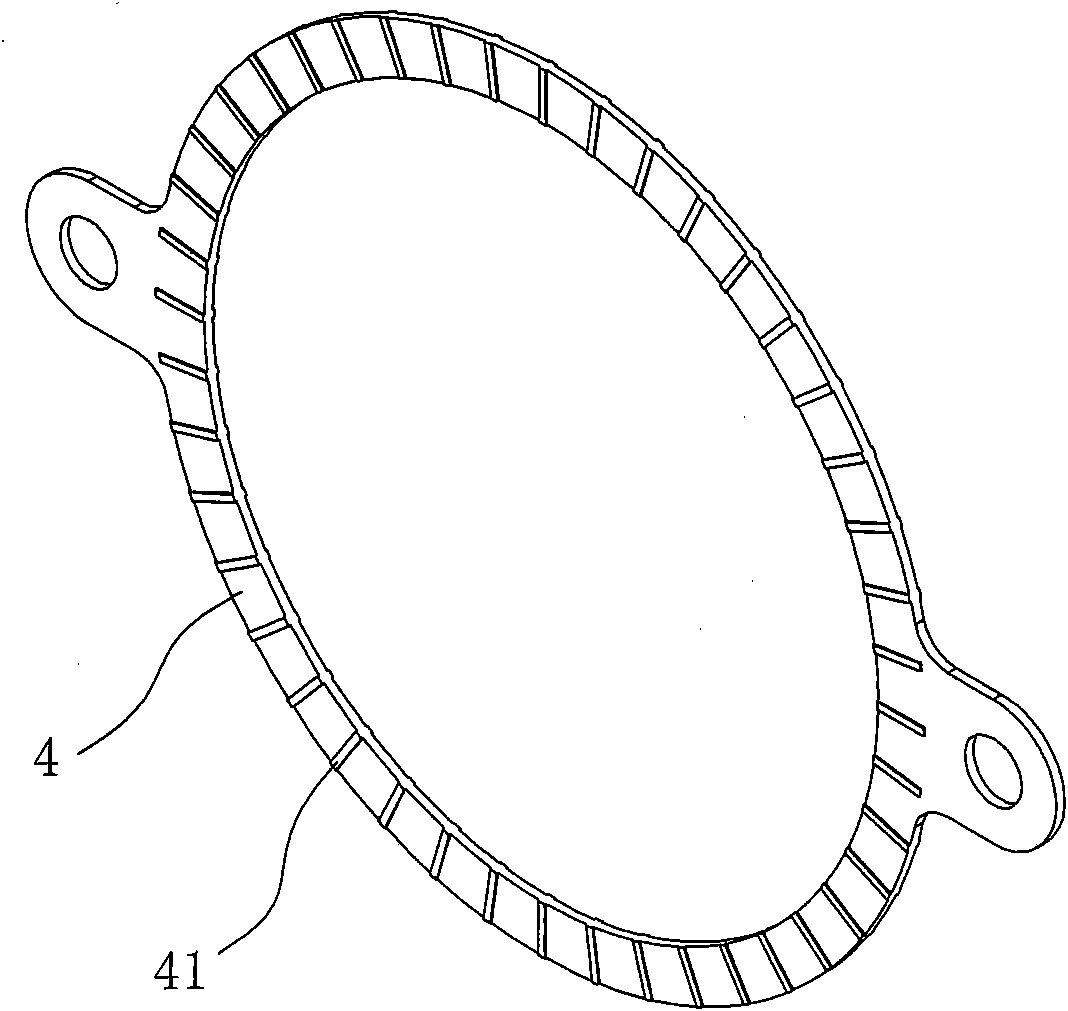

[0017] Such as figure 1 , figure 2 , image 3 As shown, the screw extrusion sludge dewatering machine includes an organic base 1, a water inlet part 13, a mud outlet part 14, a water outlet part, a screw shaft 2 that runs through the machine base 1 and has a helical blade 21 on the periphery, and A filter group composed of a plurality of annular static filter discs 3 and annular dynamic filter discs 4 intersecting and spaced on the periphery of the screw shaft 2;

[0018] Wherein, the machine base 1 includes a fixed frame 12 and a plurality of parallel support plates 11 fixed on the fixed frame 12. In this embodiment, three support plates 11 are provided, and the front end of the screw shaft 2 Part 22 penetrates through the through hole on the support plate 11 on the front side in the machine base 1, and a back pressure plate 5 is also fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com