Method for controlling a coffee machine grinder

A coffee machine and grinder technology, applied in the field of controlling coffee machine grinders, can solve problems such as difficult adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

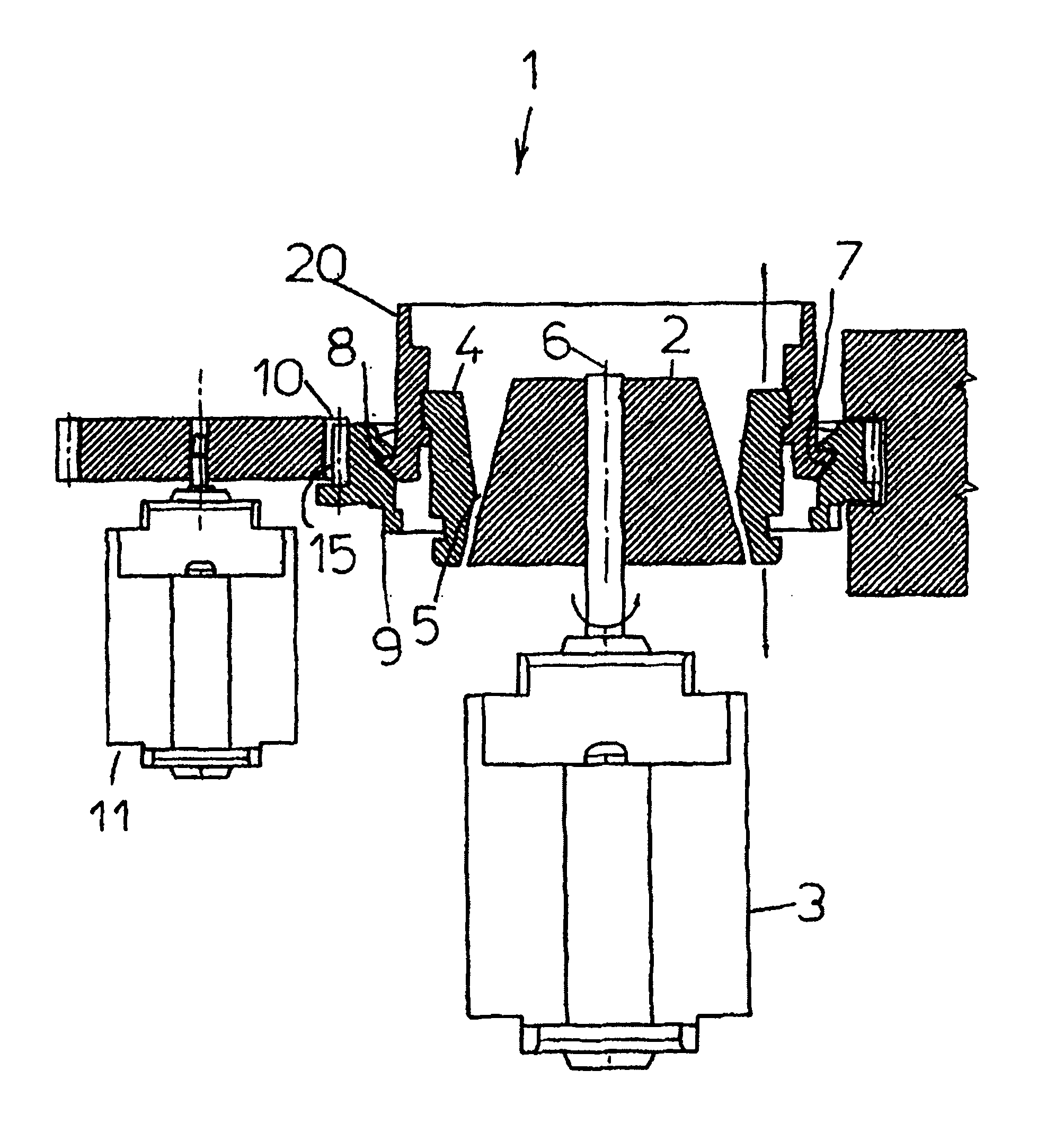

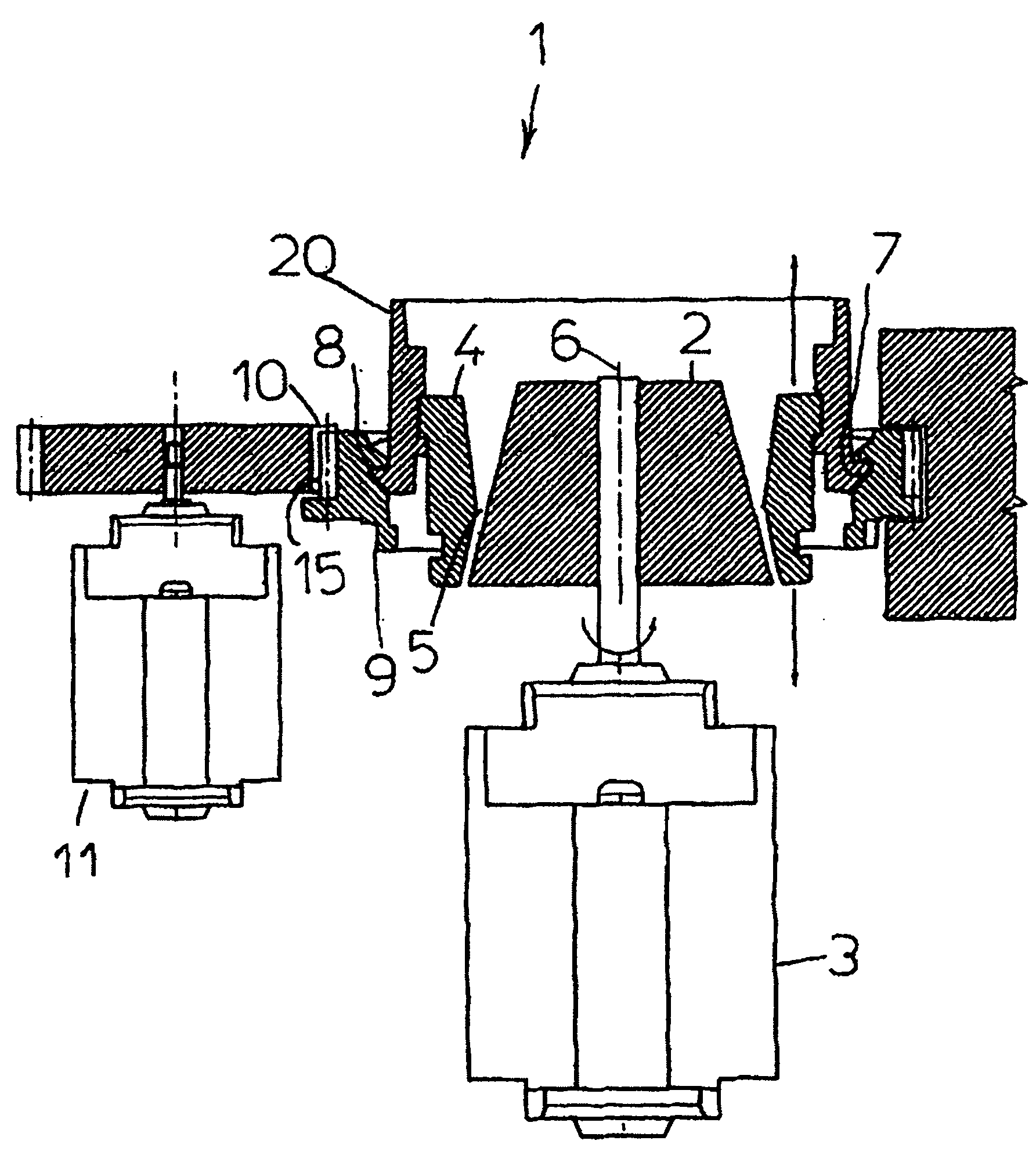

[0014] Referring to the accompanying drawings, an automatic coffee machine grinder is generally indicated by reference numeral 1 .

[0015] The grinding machine 1 comprises an inner grinding wheel 2 and an outer grinding wheel 4 which are coaxial with respect to an axis 6 and define a gap 5 which determines the size of the particles to be ground therein.

[0016] The inner grinding wheel 2 can be driven in rotation about the axis 6 by the first motor 3, while the adjusting ring nut 9 of the gap 5 is in operative engagement with the outer grinding wheel 4, so that the latter (outer grinding wheel 4) translates parallel to the axis 6 in order to be able to modify the gap 5 its own width.

[0017] Specifically, the teeth 7 protruding radially from the periphery of the support cup 20 of the outer grinding wheel 4 engage with a cam profile 8 provided along the inner side wall of an adjusting ring nut 9 which in turn has external teeth 15 which in turn Meshes with a gear 10 carried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com