Device and method for processing cleaning fluids

A cleaning liquid and equipment technology, applied in the direction of using liquid cleaning method, cleaning method and utensils, filtration treatment, etc., can solve the problems of abandoning large storage tank volume, reducing practicability, long downtime, etc., and achieving pump power Minimize, increase utility, high traffic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

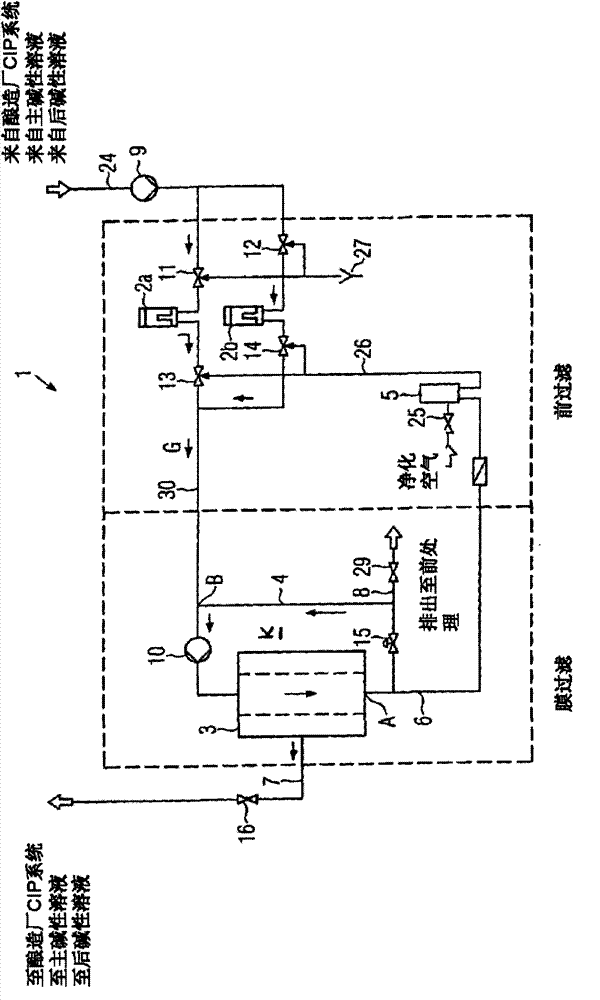

[0027] According to the invention, a washable coarse filter such as a disc filter 2 is combined with a cross-flow filter 3 for the treatment of contaminated cleaning liquids occurring in breweries.

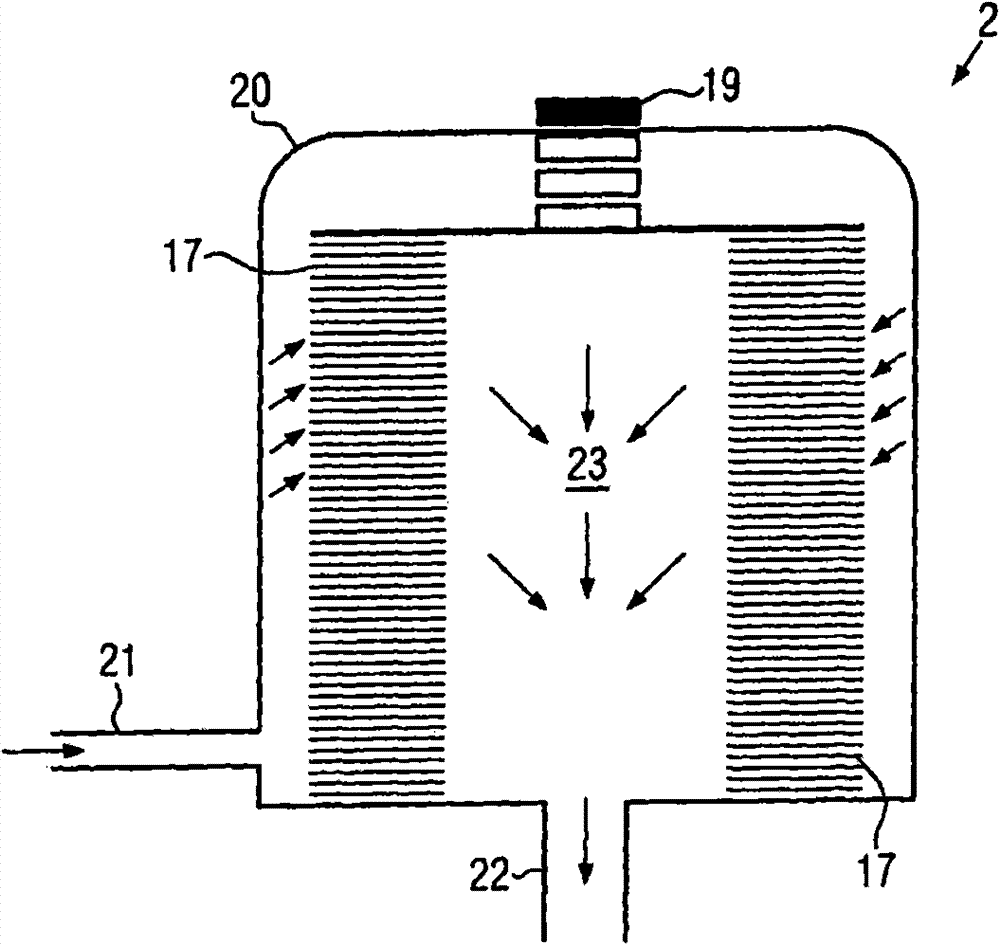

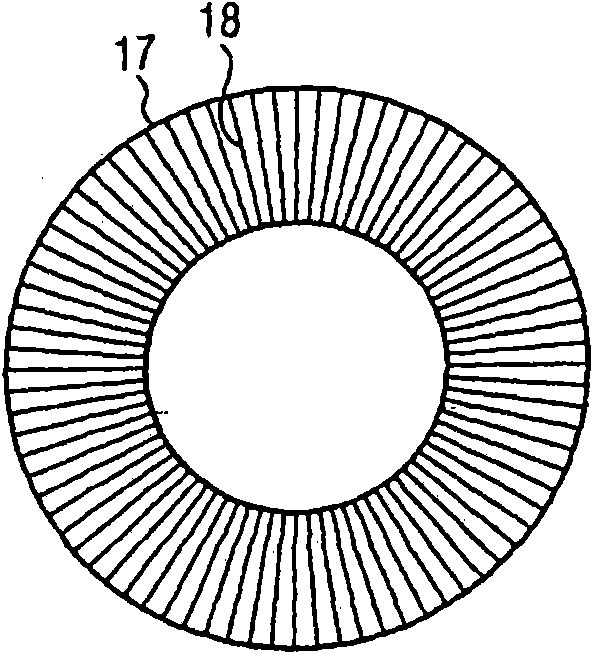

[0028] For example, a disc filter is shown in Figures 2a and 2b. The disc filter comprises a filter housing 20 as well as a raw liquid supply 21 and a crude filtrate outlet 22 . According to the present invention, the cleaning liquid is supplied to the disc filter 2 through the supply unit 21 . The disc filter 2 comprises a plurality of filter discs 17 arranged one above the other. As can be seen from FIG. 2b, the filter disk 17 is designed as a filter ring. The filter discs 17 are pressed together by the elastic force of the spring 19 . The filter disc comprises ribs 18 on at least one side. Preferably, the groove or ridge 18 extends substantially radially outwards. The ribs of the stacked discs 17 thus form filter holes through which unfiltered liquid passes through the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| filtration precision | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com