Tufting machine

A technology of tufting machine and yarn, which is applied in the field of tufting machines, and can solve the problems of complex structure and inability to produce pile fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

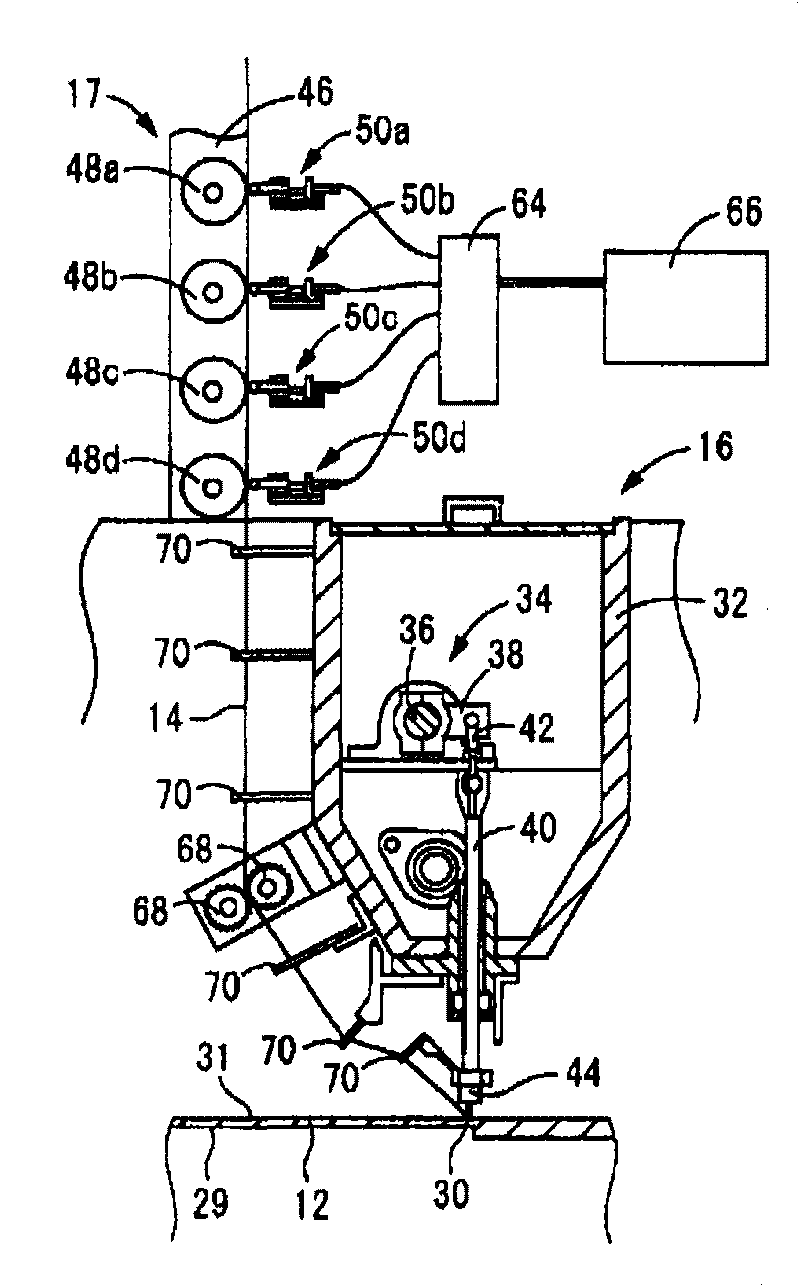

[0037] Hereinafter, in order to clarify the present invention more specifically, embodiments of the present invention will be described in detail with reference to the drawings.

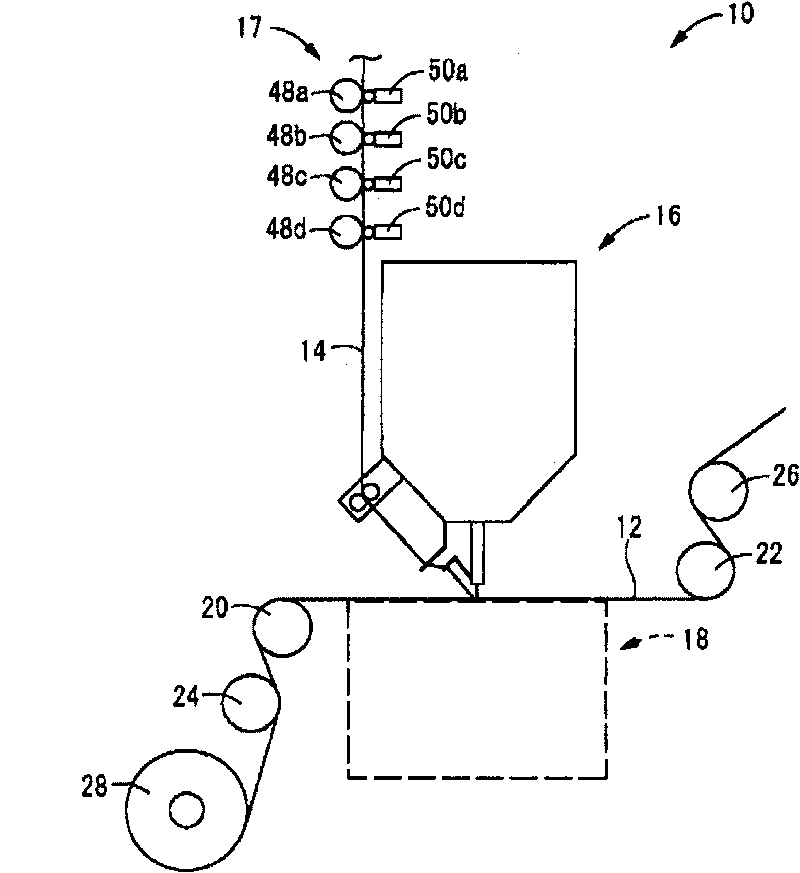

[0038] First, in figure 1 In , the outline|summary of the tufting machine 10 which is one Embodiment of this invention is shown. The tufting machine 10 is constituted as follows: above the base fabric 12 developed in the substantially horizontal direction, an implanting mechanism 16 for implanting the yarn into the base fabric 12 and a thread supply device for supplying the yarn 14 to the implanting mechanism 16 are provided. The thread feeding mechanism 17, on the other hand, is provided with a fluff mechanism 18 for forming fluff under the base fabric 12. In addition, in the following description, unless otherwise stated, the so-called up and down directions refer to figure 1 in the up and down direction.

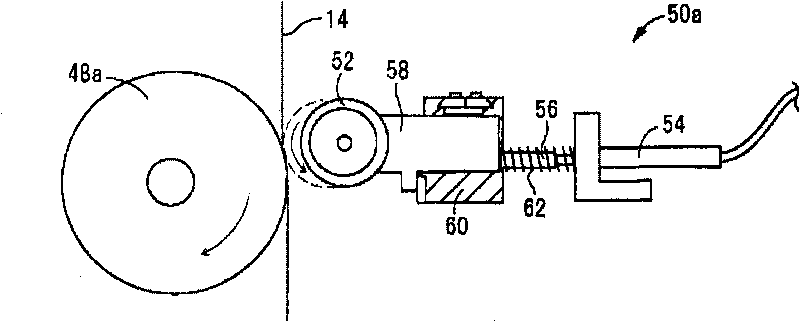

[0039] In more detail, on both sides in the horizontal direction of the fluff mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com