Soft and hard combined traction method for long-cable installation of cable-stayed bridge

A technology of soft traction and cable-stayed bridges, applied to cable-stayed bridges, bridge forms, bridges, etc., can solve the problems of long traction distance, large traction force of long cable installation, etc., and achieve the effect of convenient docking and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

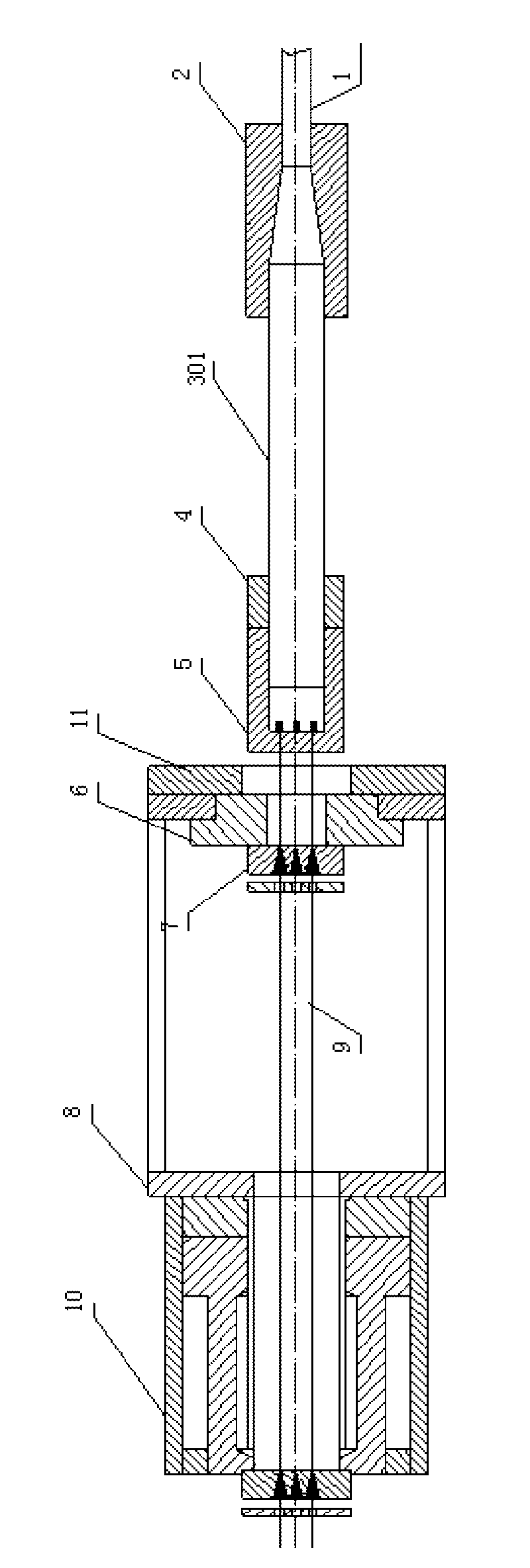

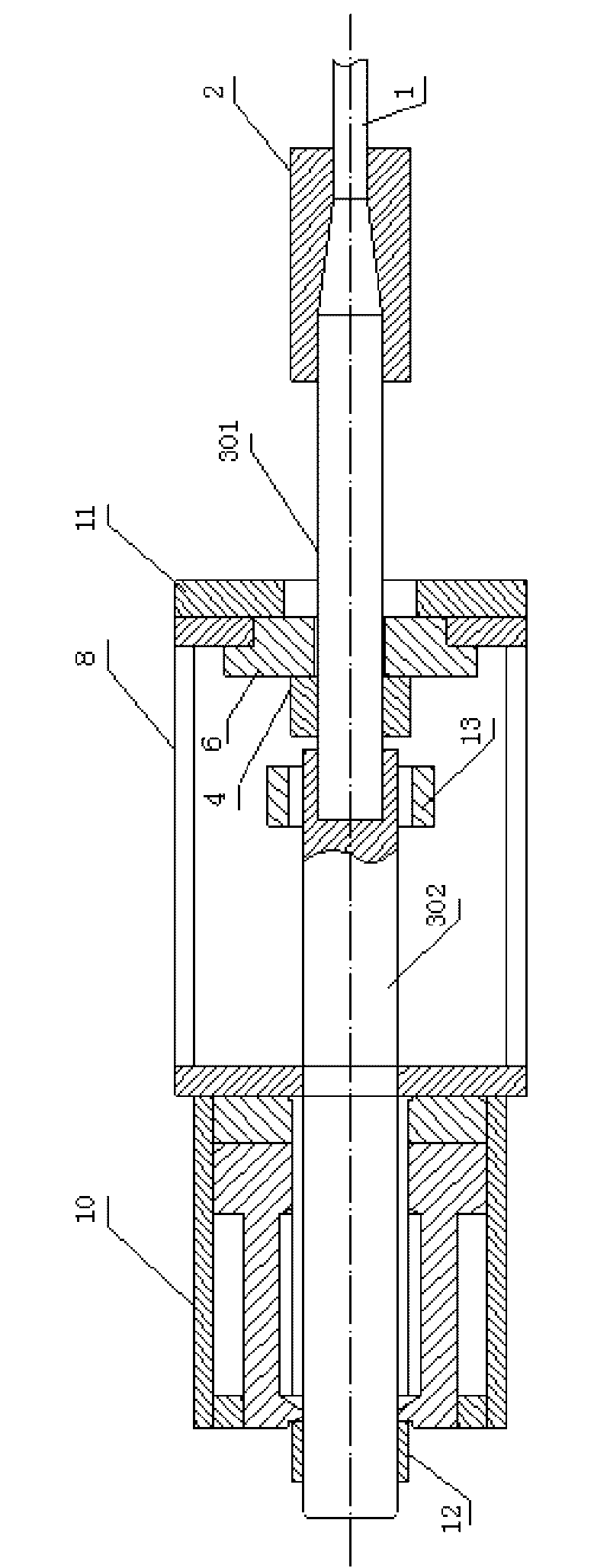

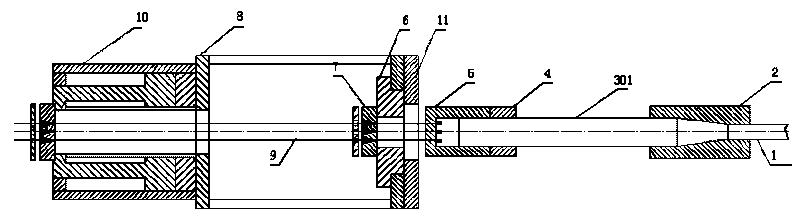

[0010] Such as figure 1 and figure 2 As shown, the long cable of the cable-stayed bridge is installed with soft and hard combined traction devices, including: cable-stayed cable 1, cable-stayed anchor head 2, thin tension rod 301, thick tension rod 302, tension rod anchor nut 4, soft traction head 5. Auxiliary anchor backing plate 6, soft traction self-locking tool anchor 7, support foot 8, soft traction steel strand 9, jack 10, stay cable anchor back plate 11, tool nut 12, stay cable anchor nut 13. The center part of the bottom of the support leg 8 and the jack 10 has the lower shuttle hole for the shuttle thick tension rod 302, the stay cable anchor pad 11 at the top of the support leg 8 has the upper shuttle hole for the shuttle soft traction head 5, the lower shuttle hole and the upper shuttle hole On one axis, one end of the thin tension rod 301 is connected to the stay cable 1 through the cable anchor head 2, and the bottom of the thin tension rod 301 is fixed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com