Edge milling machine

An edge milling machine and host technology, applied in milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problems of poor workpiece clamping rigidity, low precision of dovetail guides, affecting milling accuracy, etc., and achieve workpiece clamping rigidity. Good, good heat dissipation and chip removal effect, simplified design and production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

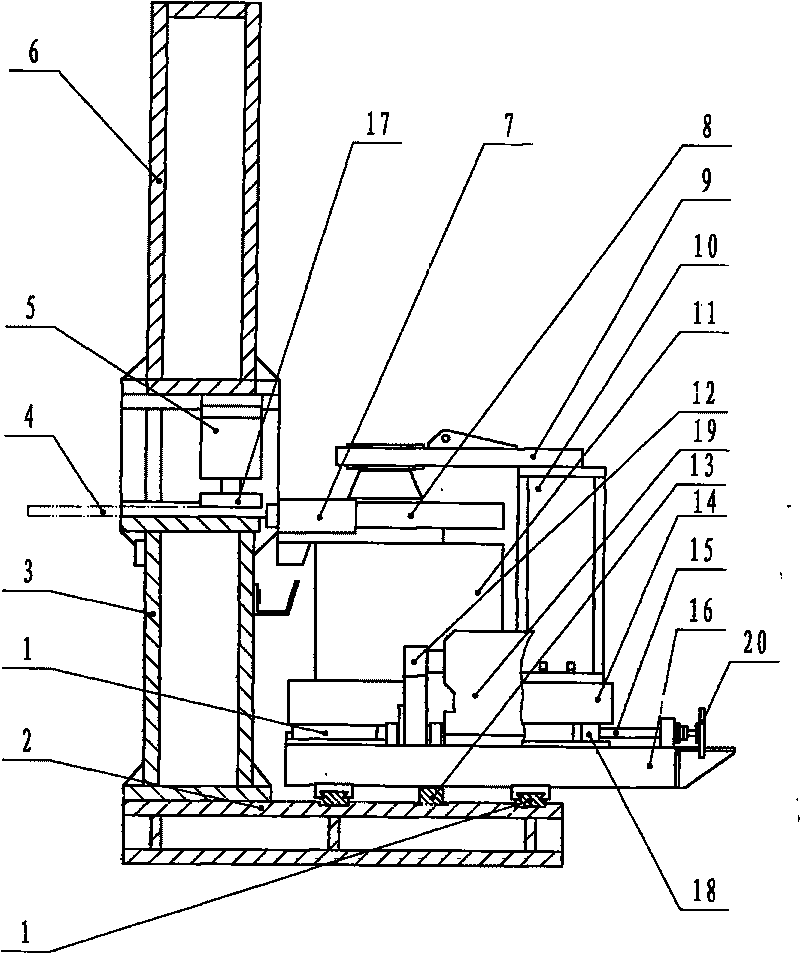

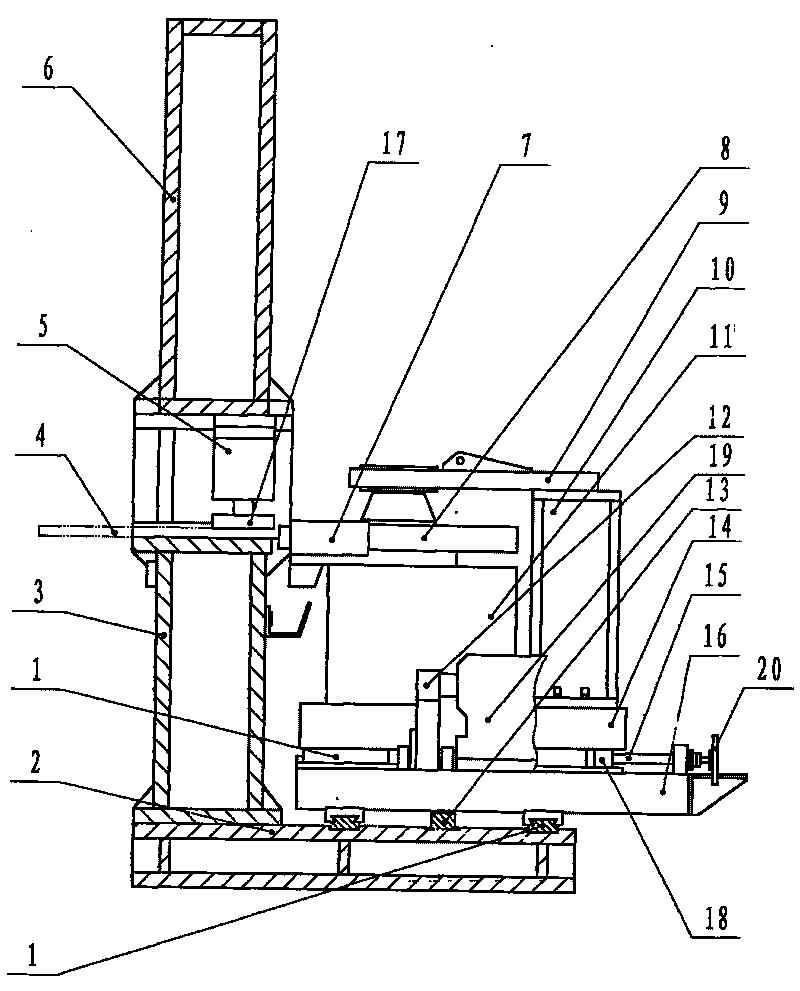

[0008] Referring to the drawings, it includes a bed 3, the bed is fixed on the base 2, the upper beam 6 is fixed on the bed 3 through the connecting beam, and 12 oil cylinders 5 of its clamping structure are evenly fixed on the upper beam 6, and the oil cylinders 5. There is a plywood presser foot 17 below; the main machine 11 is fixed on the horizontal support plate 14, and the main shaft of the main machine is equipped with a cutter head 8; the lower part of the vertical support plate 16 of the cutter mechanism is fixed on the slider of the lower slider guide rail assembly 1, and the slider The guide rail of the guide rail assembly 1 is fixed on the base 2; the motor reducer 19 of the cutting mechanism is fixed on the vertical support plate 16, and the motor reducer 19 is equipped with a gear 12, which meshes with the rack 13, and the rack 13 is fixed to the base 2, the screw nut 18 of the feed mechanism is fixed on the horizontal support plate 14, the screw 15 is screwed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com