Method for reducing harmful components by mechanical device

A mechanical device, a technology of harmful components, applied in waste heat treatment, furnace, lighting and heating equipment, etc., can solve the problems of secondary pollution, regardless of use, loss of heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

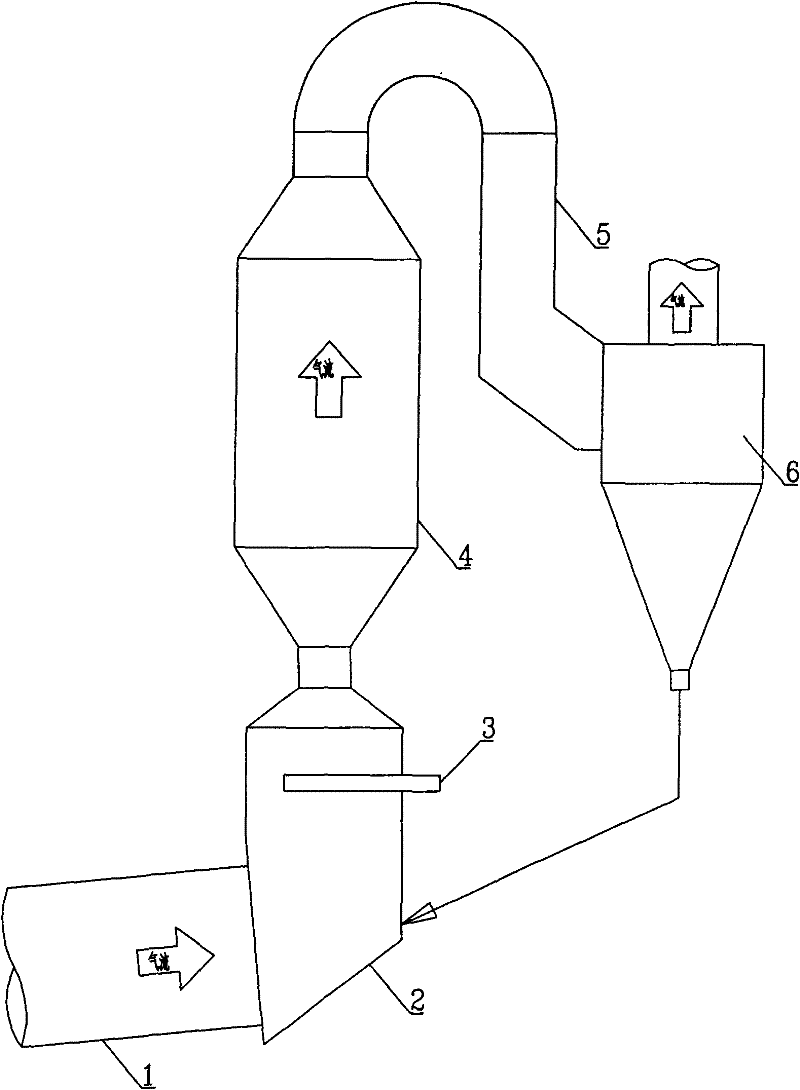

Embodiment 1

[0021] The mechanical device 3 is fixed or movable on the kiln tail smoke chamber 2 , and part of the mechanical device 3 extends into the kiln tail smoke chamber 2 .

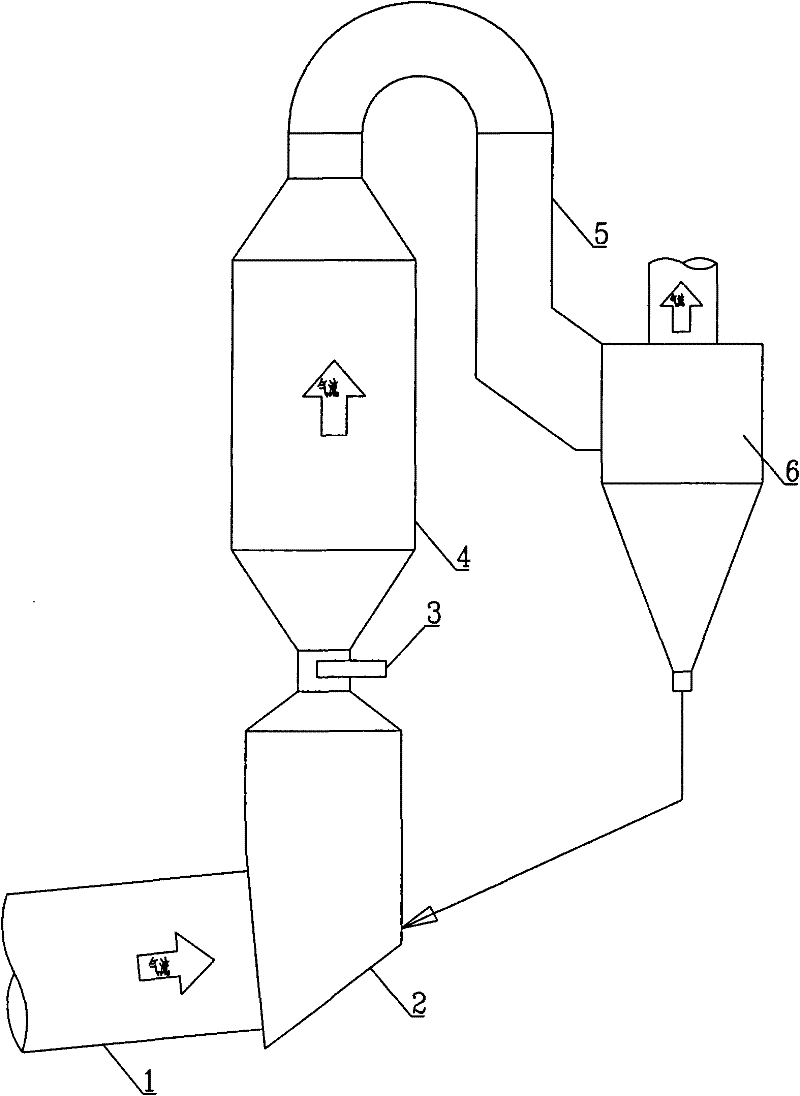

Embodiment 2

[0023] The mechanical device 3 is fixed or movable on the connecting pipe between the kiln tail smoke chamber 2 and the calciner 4 , and part of the mechanical device 3 extends into the calciner 4 .

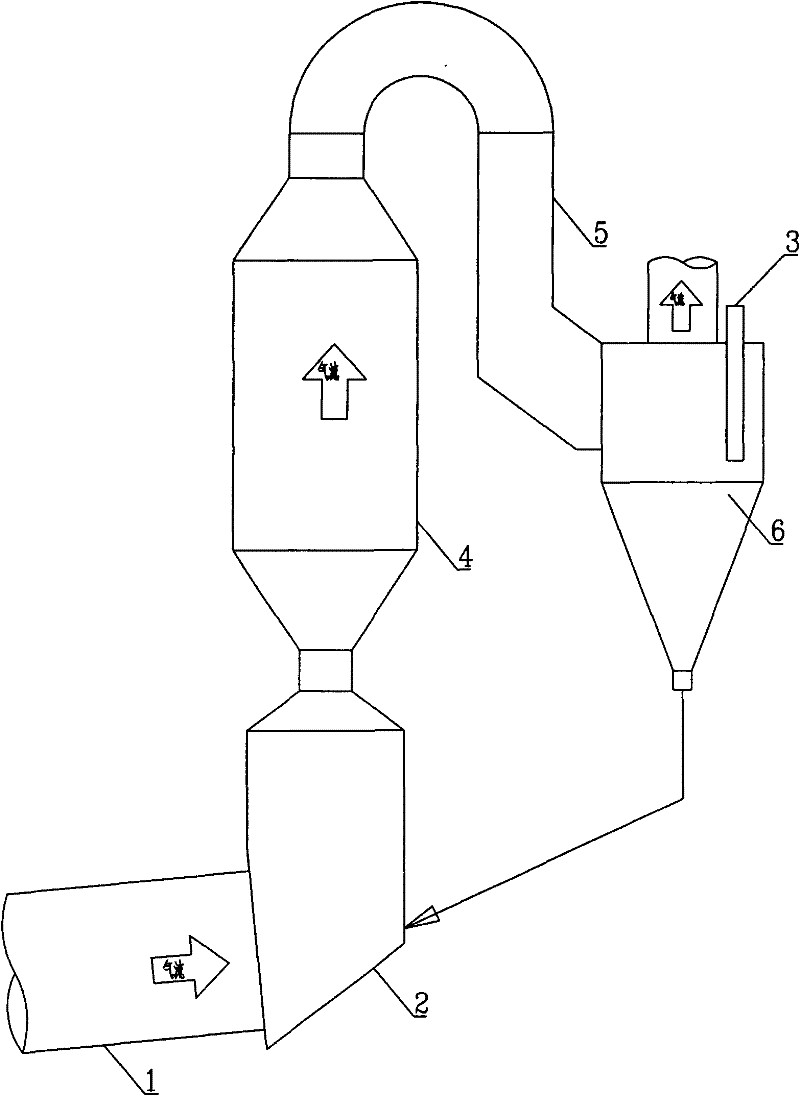

Embodiment 3

[0025] The mechanical device 3 is fixed or movable on the preheater system 6 , the preheater system 6 is used as a downstream device, and the mechanical device 3 partially extends into the preheater system 6 .

[0026] The mechanical device 3 can be installed in the downstream equipment such as the kiln tail smoke chamber 2 or the decomposition furnace 4 or the preheater system according to the nature of the harmful components that need to be eliminated. The mechanical device 3 can be in contact with the flue gas at the kiln tail, and can also be in contact with the flue gas at or downstream of the calciner 4 to condense and remove harmful substances in the flue gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com