Table centrifuge outer sleeve being capable of placing centrifuge tubes with different diameters simultaneously

A technology of centrifuge tubes and centrifuges, applied to centrifuges and other directions, to achieve the effect of cheap materials, easy to buy, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

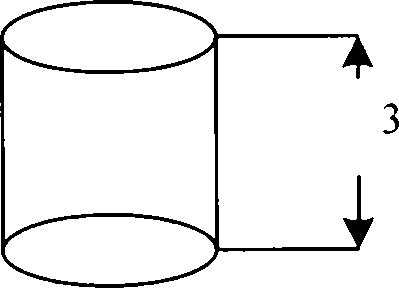

[0029] Such as Figure 1-6 As shown, an outer sleeve for placing centrifuge tubes on a desktop centrifuge includes 2-5 trays 2 of the same shape and size, a chassis 1, a cylindrical sleeve 3 with two ends open, positioning pins 4, positioning Pin fixing sleeve 6 and screw cap 5, aperture adjusting gasket 8.

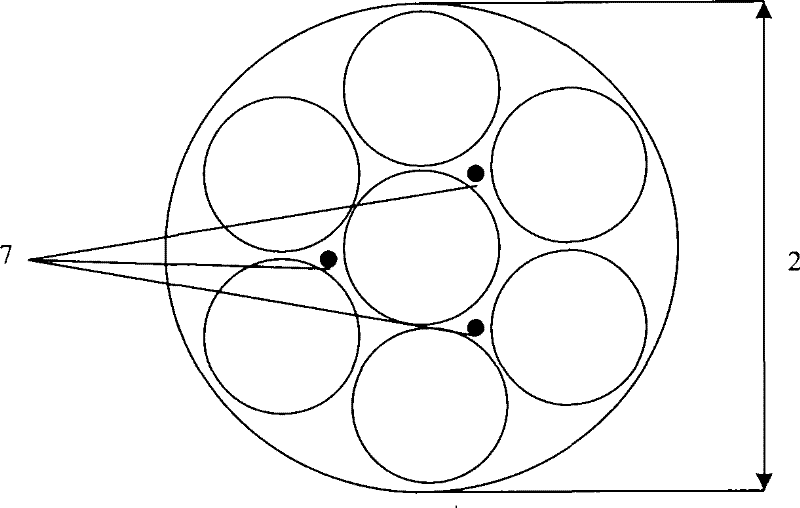

[0030] Each tray 2 is evenly provided with 7 round holes of the same diameter, and sleeves 3 are fixed in the round holes, and the heights of the sleeves 3 on the same tray 2 are the same, and their upper open end and lower open end They are respectively on the same plane; and the round holes set on different pallets 2 correspond to each other and have the same size;

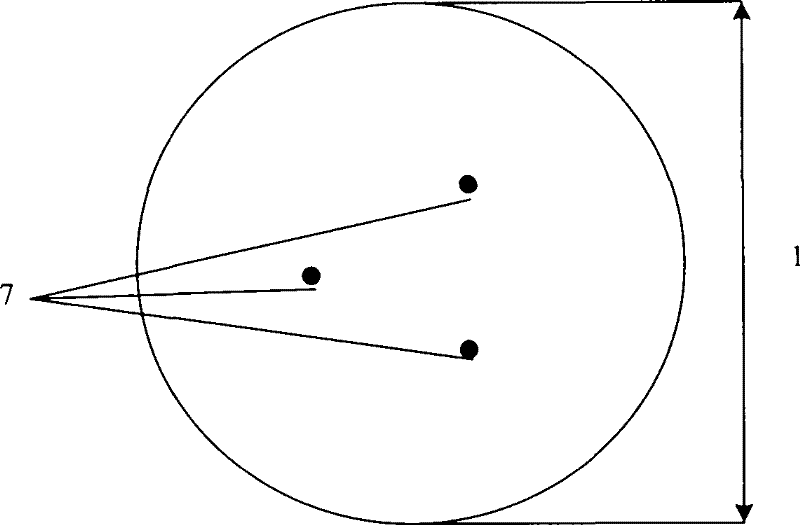

[0031] The shape and size of the chassis 1 and the tray 2 are the same, and the three trays 2 are stacked on the chassis 1 in turn, and each tray 2 is stacked with an aperture adjustment gasket 8 (the diameter of the aperture adjustment gasket is 10cm). 1. Three positioning holes 7 are symmetrically arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com