Deeply hydrodearomatized catalyst and preparation method

A technology of deep hydrogenation and catalyst, which is applied in the direction of chemical instruments and methods, hydrogenation refining of aromatics, metal/metal oxide/metal hydroxide catalyst, etc. Suitable for deep hydrodearomatization process, weak acidity and other problems, to achieve the effect of improving anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: This example illustrates the preparation of amorphous silica-alumina powder.

[0023] Aluminum chloride is added to distilled water, stirred until dissolved to obtain an aluminum-containing compound aqueous solution (a), and the concentration of aluminum ions in the solution is 2wt%; commercially available ammonia water is added into an appropriate amount of distilled water to dilute to obtain a precipitant with an ammonia ion concentration of 10wt% Solution (b): adding appropriate amount of distilled water to industrial water glass to dilute to obtain solution (c) with silicon dioxide content of 60 wt%.

[0024] Take a steel reaction tank, add distilled water and stir in the tank, after heating to 60°C, open the valves of the containers containing solutions (a) and (b) respectively, maintain the reaction temperature, control the flow rate, and make the pH of the reaction system The value is maintained at 7.0-7.2, and the neutralization reaction time is compl...

Embodiment 2~9

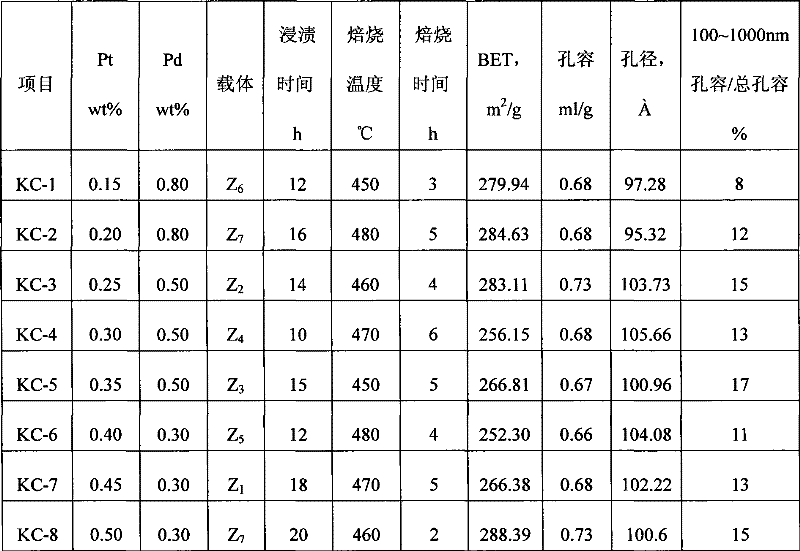

[0028]According to the experimental procedure of Example 1 and the raw materials and operating conditions shown in Table 1, powder F with different properties can be obtained 2 , F 3 , F 4 , F 5 , F 6 , F 7 , F 8 , F 9 ; The obtained powder properties are shown in Table 1.

[0029] Table 1 The physical and chemical properties of the powder obtained in Example 1

[0030]

Embodiment 10

[0031] Example 10: This example illustrates the shaping of the carrier.

[0032] The powder obtained in Example 1 has a total pore volume of 0.43ml / g and a surface area of 230m 2 The pseudo-boehmite (f) of / g is mixed evenly, and the addition of pseudo-boehmite is 15% of the weight of the molding carrier, and then 3% of the binder silica sol (g) of the weight of the molding carrier is added, after kneading Extrusion molding. After the mixed powder is kneaded and extruded, it is dried in the air atmosphere at 120°C for 5 hours, and then heated to 450°C for 6 hours to obtain the shaped carrier Z 1 , the properties of the obtained carrier are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com