Dynamic sealing vertical self sucking pump with high suction lift

A self-priming pump and sealing type technology, applied in the field of high-suction vertical self-priming pump, can solve the problems of cavitation, long self-priming time, easy leakage of shaft seal, etc. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

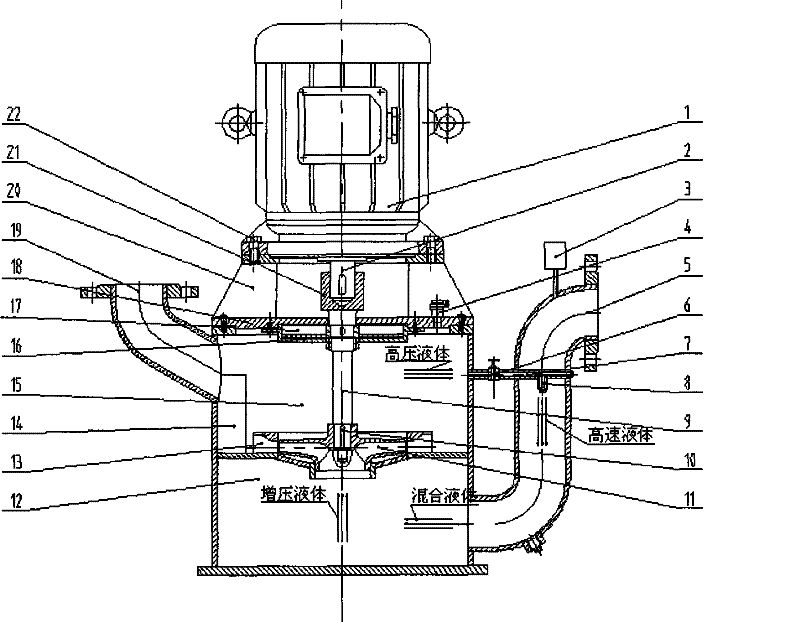

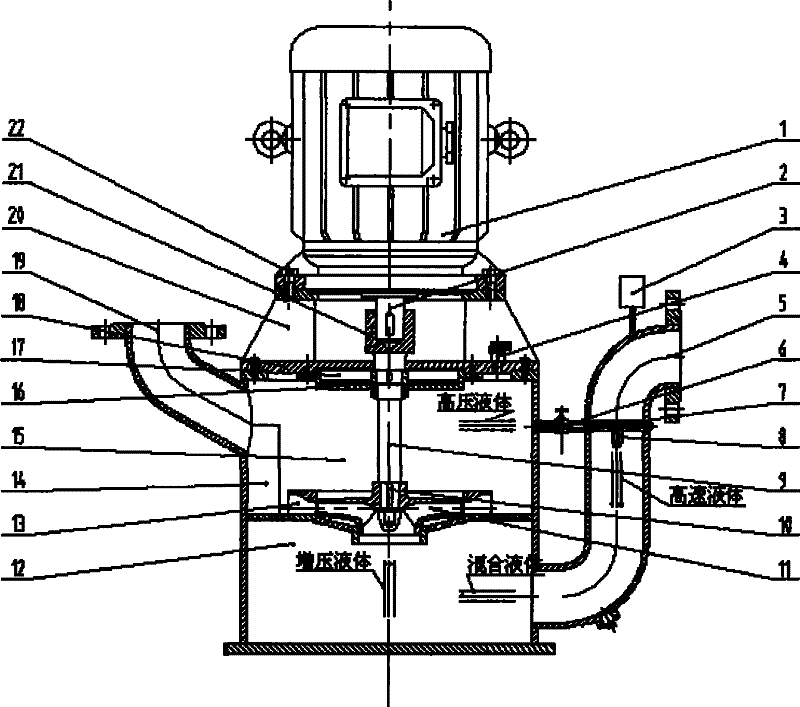

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0010] Depend on figure 1 It can be seen that the present invention includes: the motor 1 is connected and fixed on the pump bracket 20 by screws 22, the pump casing is composed of the pump water suction chamber 12 and the pump pressure water chamber 15, and is connected with the pump bracket 20; the left and right sides of the pump casing are provided with There is a self-priming pump inlet 5 and a pump outlet 19; an electromagnetic vacuum breaker valve 3 is provided at the 5 inlet of the self-priming pump, and an automatic exhaust valve 4 is provided on the upper part of the pressure water chamber 15 of the pump casing; the impeller 11 is connected to the pump through the connection key 10 The shaft 9 is connected, and the periphery of the impeller 11 is provided with a guide vane type gas-liquid mixer 13, and a partition 14 is provided betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com