Polishing device for steel box girder T rib sliced mouth

A technology of steel box girder and cutout, which is applied in the field of steel box girder T-rib cutaway grinding device, which can solve the problems of low production efficiency and high labor intensity, and achieve the effects of improving production efficiency, reducing production cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

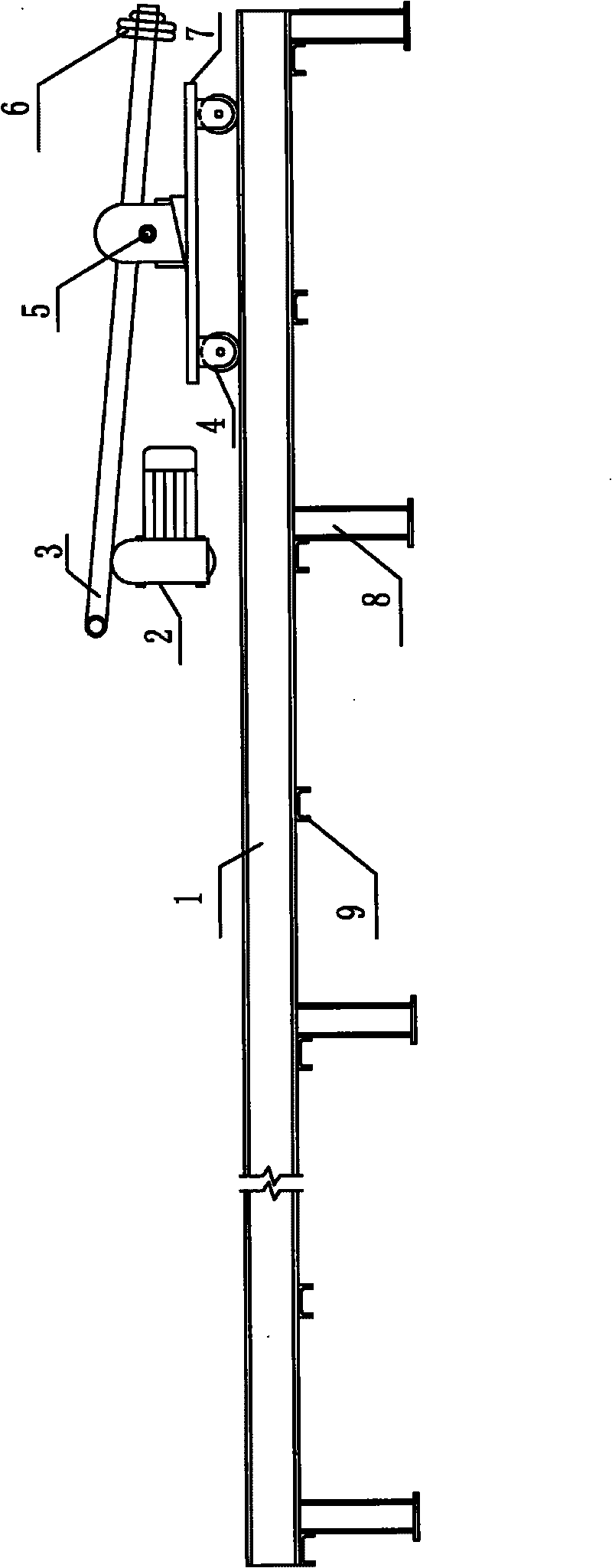

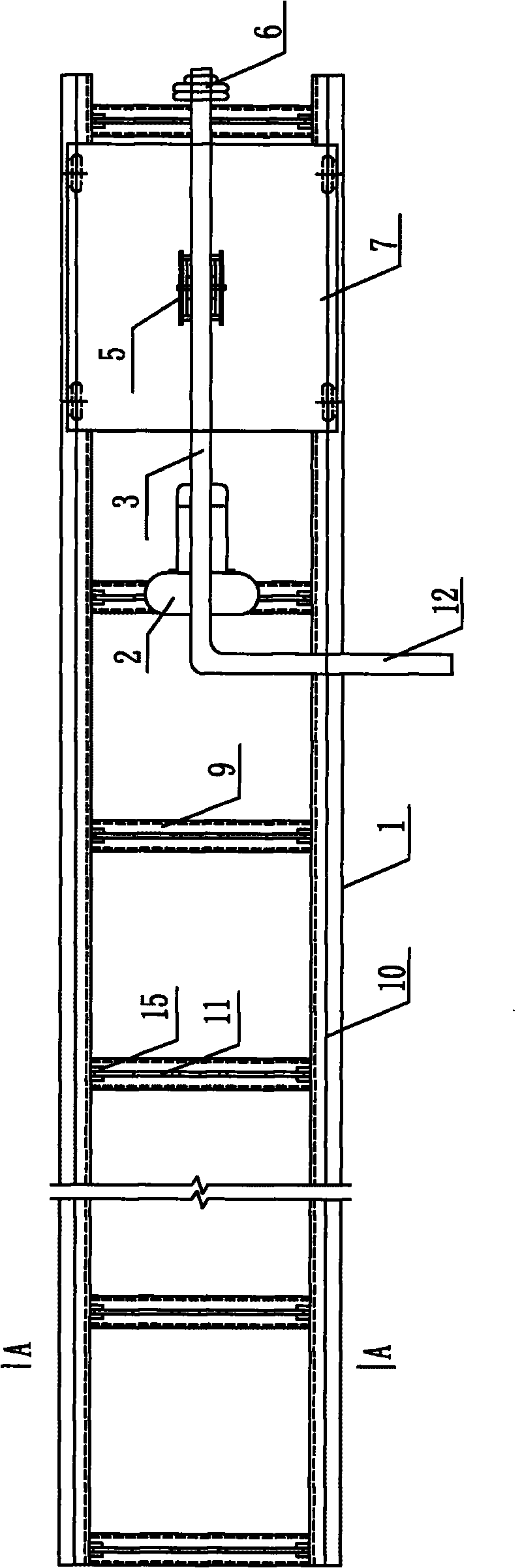

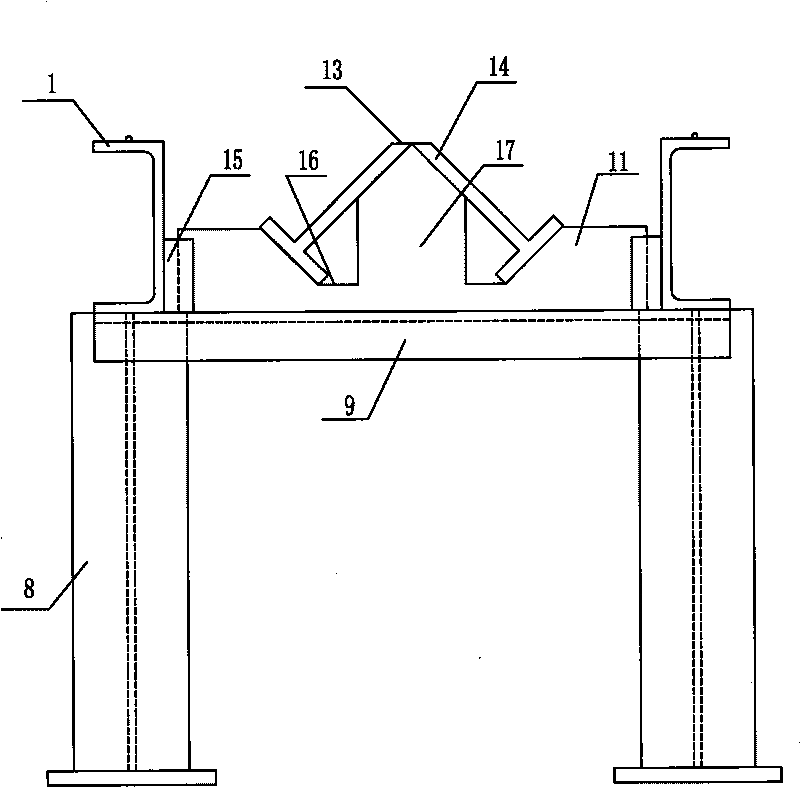

[0013] In order to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the embodiments and accompanying drawings, see Figure 1 to Figure 3 :

[0014] A steel box girder T-rib slit grinding device implemented according to the present invention is composed of a tire frame, a clamp, a walking trolley 7, a grinder mounting frame, and a grinder 2, and the tire frame includes a column 8, a cross beam 9 and a track beam 1. The column 8 stands in two straight lines on the ground foundation to support the beam 9 and the track beam 1. The track beam 1 is two channel steels, which are connected longitudinally to the top of the two columns 8, and the beam 9 is transversely connected to the Two channel steels, columns 8, beams 9 and track beams 1 are connected to form a frame structure, which stands stably. Track beam 1 upper surface is provided with slideway 10, and the width of slideway 10 is sligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com