Mouse profiling machine

A technology of copying machine and mouse, applied in the field of mouse copying machine, can solve the problems of difficult to adapt to mouse processing and production, low production efficiency of bamboo mouse, complicated production process, etc. less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

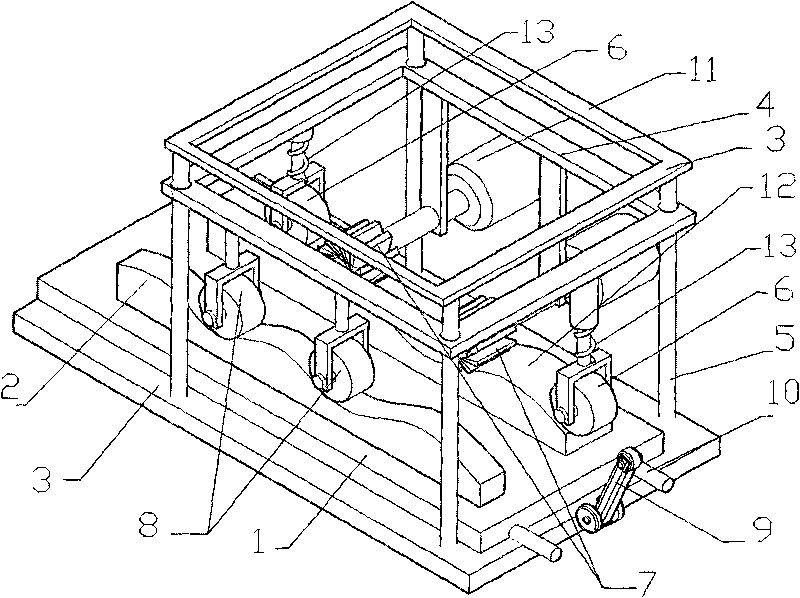

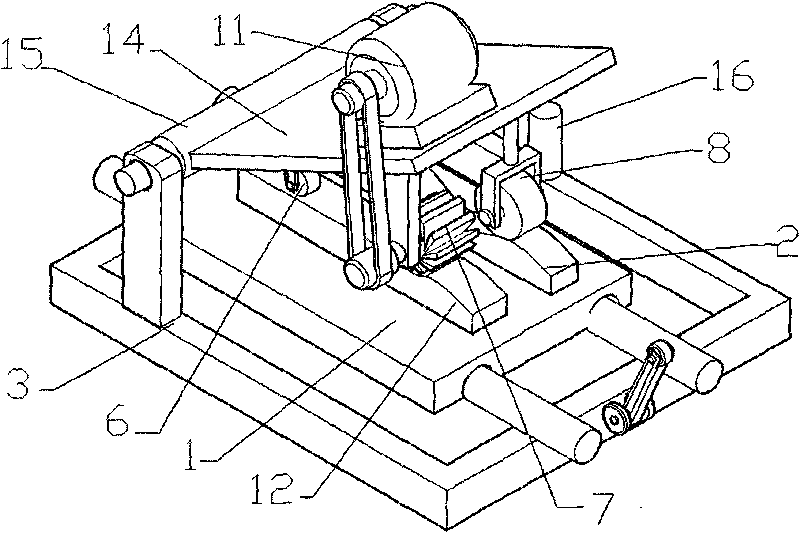

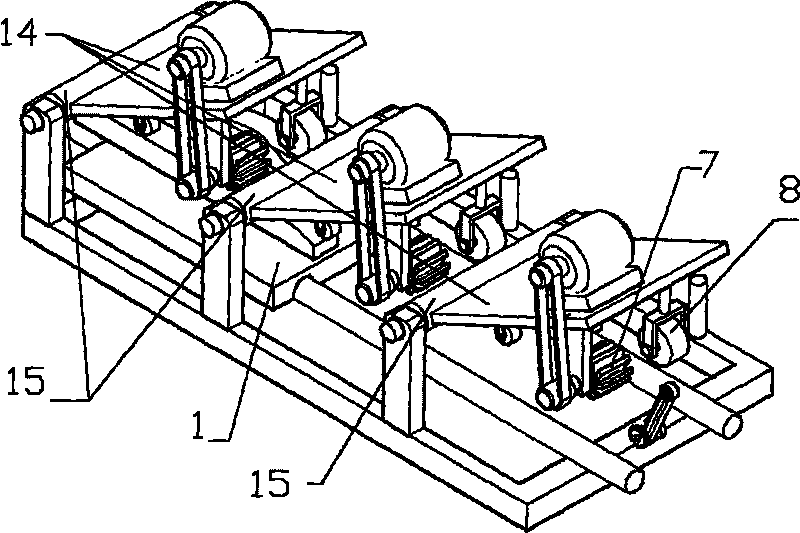

[0019] The present invention will be further described through embodiment now in conjunction with accompanying drawing. like figure 1 As shown, the carriage 4 is slidably connected to the vertical guide rod 5 through the through holes at its four corners up and down, and the vertical guide rod 5 is fixedly connected to the frame 3 . The workbench 1 is connected to the machine frame 3 through a longitudinal guide rod 10 located under the carriage 4 so as to be slidable back and forth. Two arc-shaped hobs 7 are connected longitudinally on the carriage 4, one front and the other behind. The spring 13 is connected to the carriage 4 . The two track wheels 8 are connected to the carriage 4 in a longitudinal direction, one in front and one behind, corresponding to the sides of the two arc-shaped hobs 7 respectively. The driving motor 11 of the arc hob 7 is also located on the carriage 4 . The rear portion of the frame 3 is connected with a limit switch 9 corresponding to the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com