Star sensor calibrator and method for calibrating high-precision star sensor

A technology of star sensor and calibration device, applied in the direction of measuring device, instrument, etc., can solve the problems of difficulty in reaching star sensor, calibration accuracy, installation accuracy and rotation accuracy limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

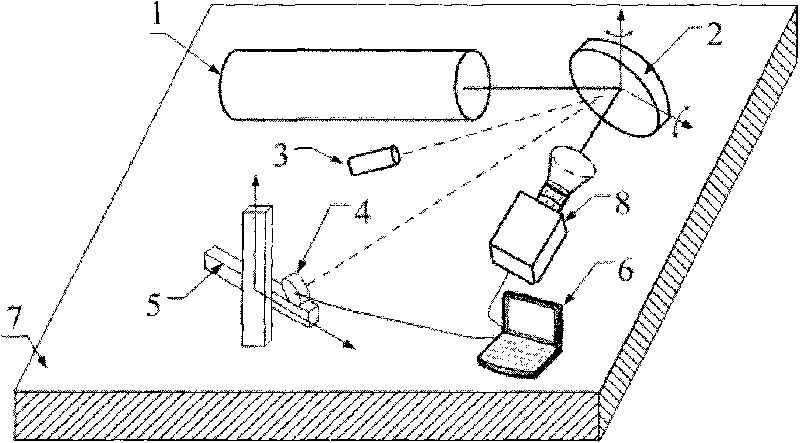

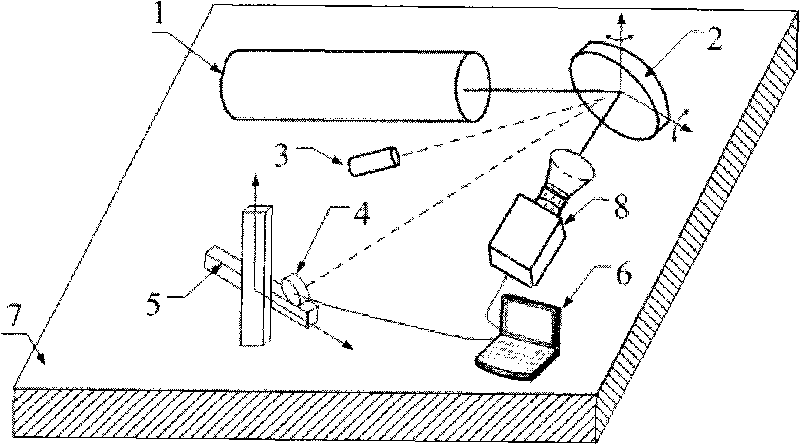

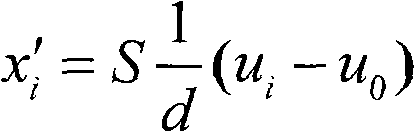

[0025] A single-star simulator 1 is placed on one side of the optical air-cushion platform 7, and a star sensor 8 to be calibrated is placed on the other side of the optical air-cushion platform 7. There is a two-dimensional adjustable plane mirror 2 on the corner, the angle between the two-dimensional adjustable plane mirror and the optical axis of the single-star simulator is 45°±15°, and the center of the two-dimensional adjustable plane mirror reaches the star to be calibrated. The distance between the sensor is 20cm, the angle between the two-dimensional adjustable plane reflector is 90°±15°, and the distance is 15cm. A high-precision two-dimensional guide rail 5 is provided at 100 cm from the center. The high-precision two-dimensional guide rail can move vertically and horizontally on the optical air cushion platform 7. The laser detector 4 of the laser angle measuring device is installed on the high-precision two-dimensional guide rail 5 , the laser light emitted by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com