Steering mechanism capable of improving friction performance and abnormal sound

A technology of friction performance and adjustment mechanism, applied in the direction of mechanical steering gear, etc., can solve problems such as excessive gap, too small, not well controlled, etc., achieve good effect, effective control of abnormal sound quality problems, and effective control of product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

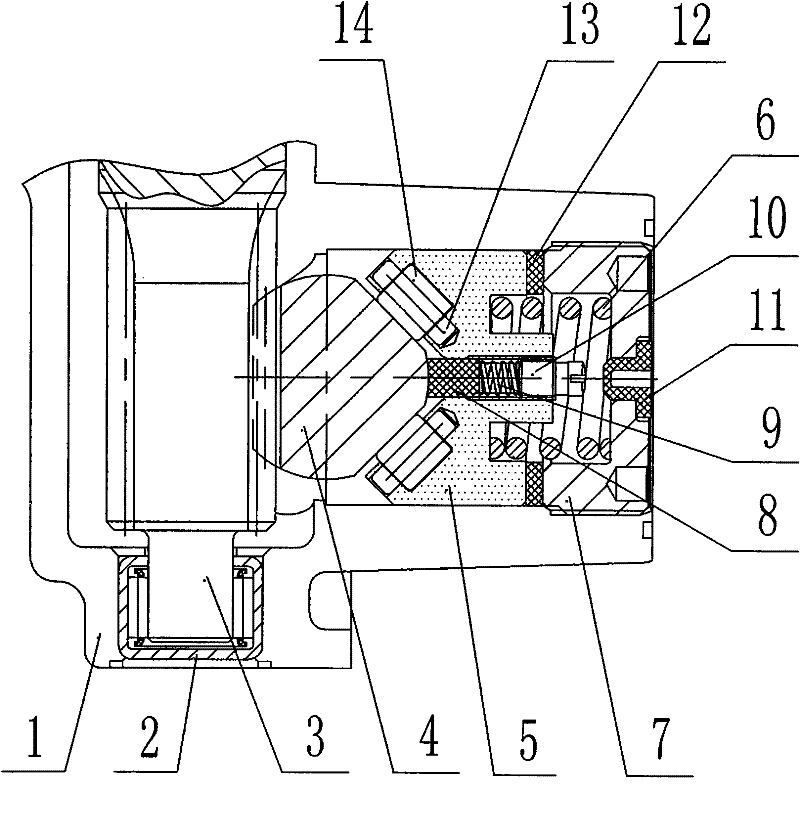

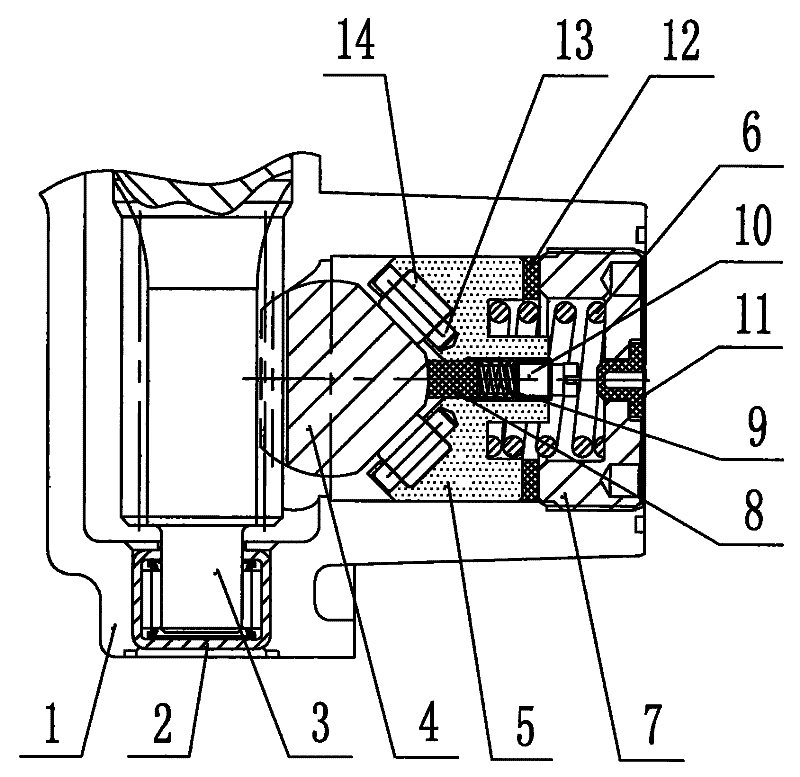

[0011] An adjustment mechanism that can improve the friction performance and abnormal noise of the steering gear, which consists of a main body shell 1, a gear shaft fixed bearing 2, a gear shaft 3, a rack 4, a rack support base 5, a rack support spring 6, and a screw plug 7. Friction block 8, friction block spring 9, friction adjustment screw 10, screw plug cover rubber plug 11, rubber gasket 12, roller support pin 13 and rack support roller 14, the main body shell 1 is fixed by the gear shaft The bearing 2 is fixed with a gear shaft 3 , the gear shaft 3 is fixed relative to the main body shell 1 , the gear shaft 3 is engaged with a rack 4 , and the rack 4 floats relative to the main body shell 1 . The back of rack 4 is designed as a V-shaped support surface. One side of rack 4 is fixed with a rack support base 5 by screw plug 7, rack support spring 6 and rubber gasket 12, and one side of rack support base 5 is designed to match the V-shaped support surface of rack 4. Consis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com