Magnetic suspension electromotive force rotary wing flying saucer

一种磁悬浮、电动力的技术,应用在航空飞行器领域,能够解决飞碟碟体不可控反扭矩等问题,达到易于实现动力控制、重量轻、克服旋翼反扭矩的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

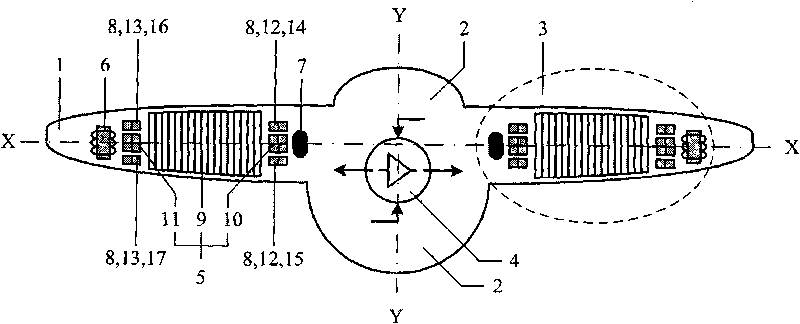

[0022] Embodiment 1: Single-rotor maglev point power rotor flying saucer

[0023] refer to figure 1 and figure 2 , the single-rotor maglev electric power rotor flying saucer includes: a dish shell 1, a disc cabin 2, a rotor system 3, and a control system 4, wherein the rotor system 3 is a magnetic levitation electric power rotor system, which consists of a magnetic levitation rotor wheel 5, an electric power ring 6, The magnetic levitation shaft 7 and the magnetic levitation guide rail 8 are composed; the electric power ring 6, the magnetic levitation shaft 7 and the magnetic levitation guide rail 8 are fixed on the disc shell 1; It is connected radially (X-X) between the magnetic levitation inner ring 10 and the magnetic levitation outer ring 11 to form an impeller; the magnetic levitation guide rail is divided into the magnetic levitation inner ring guide rail 12 and the magnetic levitation outer ring guide rail 13, and the magnetic levitation inner ring guide rail 12 is f...

Embodiment 2

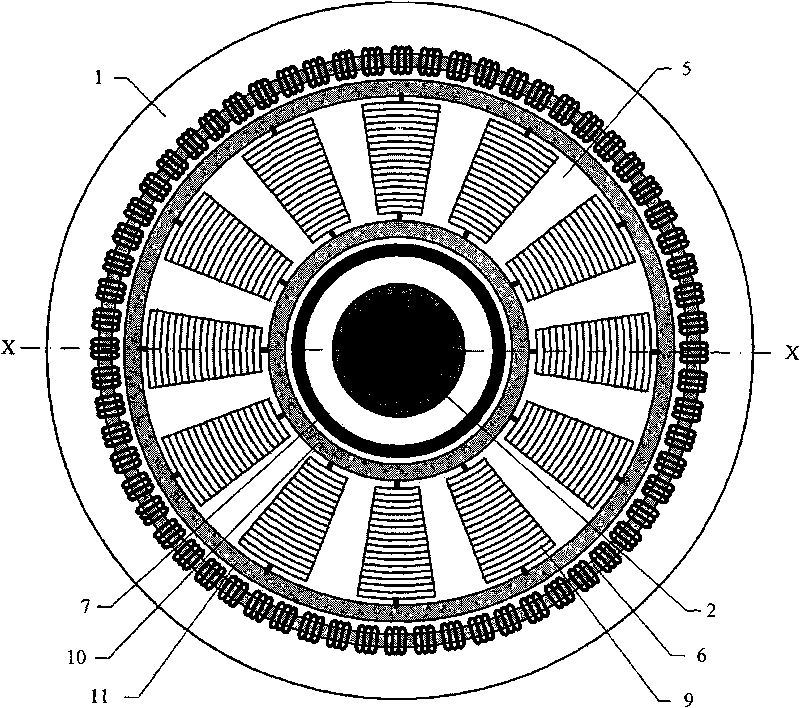

[0028] Embodiment 2: Rotor wheel radial magnetic levitation structure

[0029] A magnetic levitation electric power rotor flying saucer, the magnetic levitation rotor wheel 5 is suspended on the magnetic levitation shaft 7 in the radial direction (X-X) according to the principle of magnetic levitation.

[0030] Such as Figure 5 Design the radial magnetic levitation structure of magnetic levitation rotor wheel 5 as shown, on the outer edge of the magnetic levitation inner ring 10 of the magnetic levitation rotor wheel 5 and the magnetic levitation shaft 7, paired magnets 22 are placed, and the magnet polarity of the magnetic levitation inner ring 10 is N pole facing inward, the S pole facing outward; the magnet polarity of the magnetic levitation shaft 7 is that the S pole faces inward, and the N pole faces outward. According to the principle that like magnets repel each other, the magnetic poles N on the outer edge of the magnetic levitation inner ring 10 and the magnetic po...

Embodiment 3

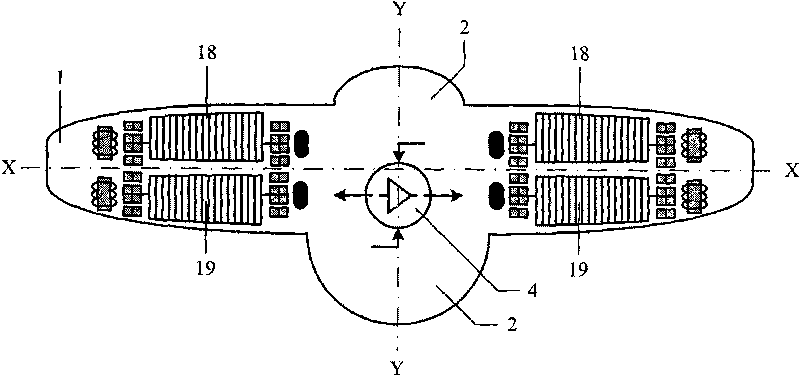

[0034] Embodiment 3: Rotor wheel axial magnetic levitation structure

[0035] A magnetic levitation electric power rotor flying saucer, the magnetic levitation rotor wheel 5 is suspended on the magnetic levitation guide rail 8 in the axial direction (Y-Y) according to the principle of magnetic levitation, that is: the magnetic levitation inner ring 10 is suspended in the upper guide rail groove 14 of the inner ring and the lower guide rail groove 15 of the inner ring Between them, the magnetic levitation outer ring 11 is suspended between the upper guide rail groove 16 of the outer ring and the lower guide rail groove 17 of the outer ring.

[0036] Such as Figure 6 The axial magnetic levitation structure of the design magnetic levitation rotor wheel 5 shown in the figure makes the magnet polarity of the magnetic levitation inner ring 10 and the magnetic levitation outer ring 11 be, the N pole is on the top, and the S pole is on the bottom; the inner ring upper guide rail groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com