Roller mill for grinding particulate material

A granular material, roller mill technology, applied in grain processing, etc., can solve the problems of expensive, hindering the shaft journal from pumping lubricant into the load area, complex and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

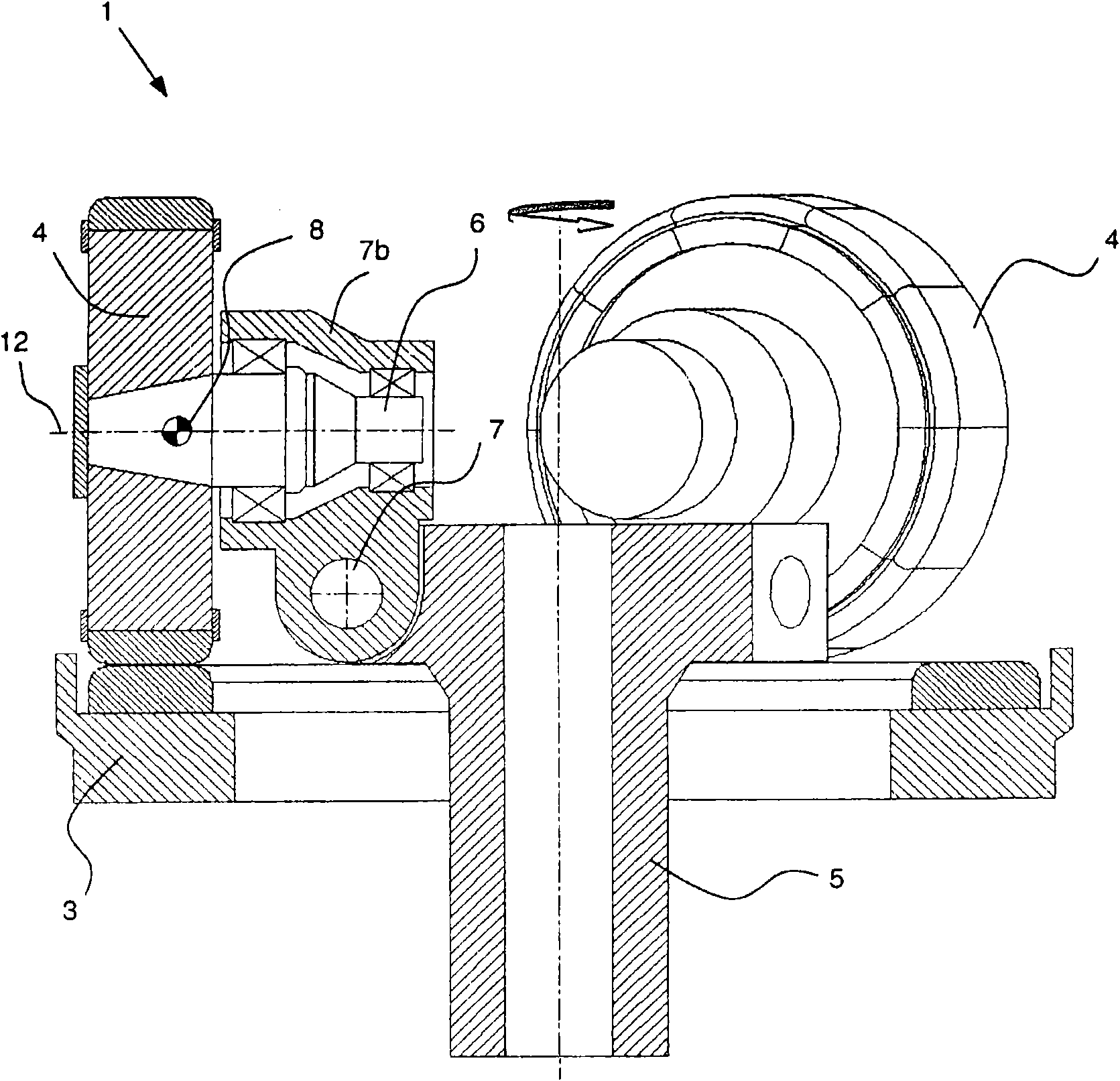

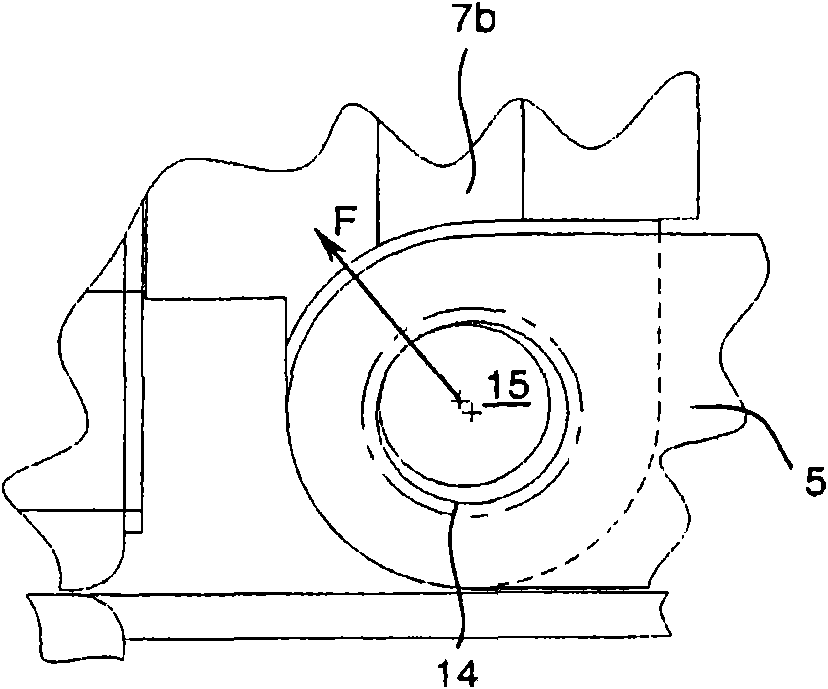

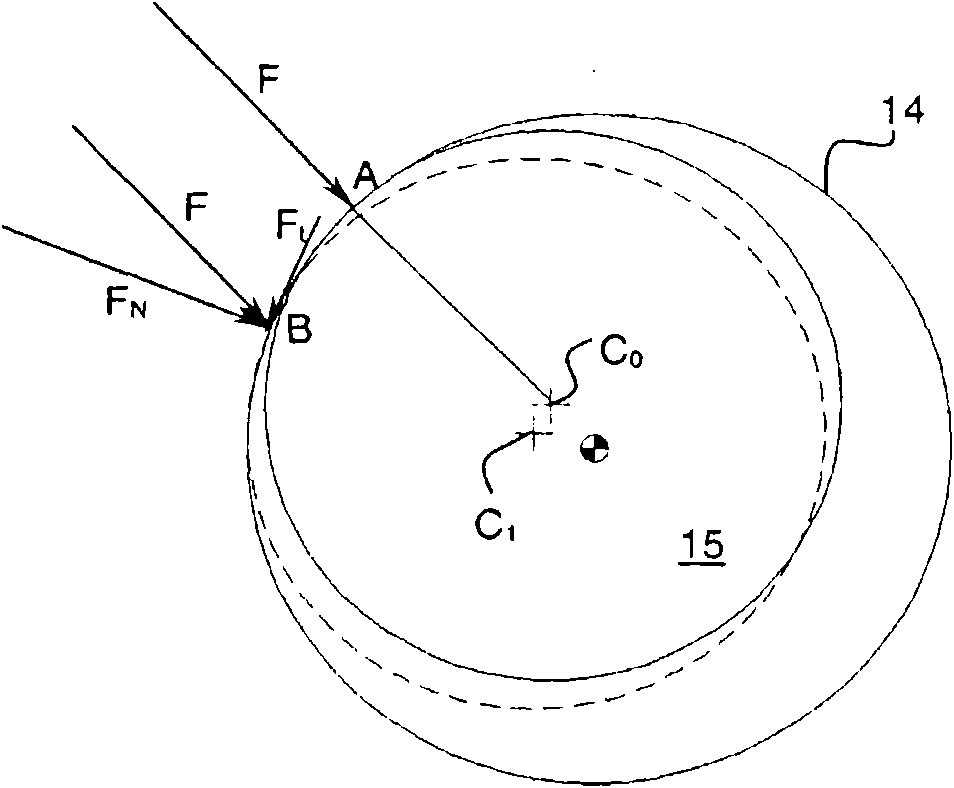

[0012] In the figure, a cross-sectional view of the roller mill 1 can be seen. The roller mill 1 includes a horizontal grinding table 3 and a set of rollers 4 cooperating therewith, the rollers being connected to a vertical shaft 5 and rotating around it. The roller 4 rotates around a separate horizontal roller shaft 6 connected to the vertical shaft 5 via a hinge connection portion 7 that allows the roller to rotate in an upward and downward direction while rotating around a vertical shaft. The centerline 12 moves freely in the plane. The plane in which the roller moves does not necessarily include the centerline of the vertical axis. In order to obtain a small sliding or shearing effect in the grinding zone, the roller is sometimes or very often rotated slightly by an angle, which means that its centerline does not always pass through the centerline of the vertical axis.

[0013] The rotation center of the hinge connection part 7 may be placed in the same horizontal plane as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com