Hydraulic oil cylinder

A technology of hydraulic oil cylinder and cylinder barrel, which is applied to fluid pressure actuating devices, valve details, engine components, etc., can solve problems such as affecting the product qualification rate, smashing the sealing surface of the steam valve, and failing to achieve the closing time of the steam valve. , to achieve the effect of improving production efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

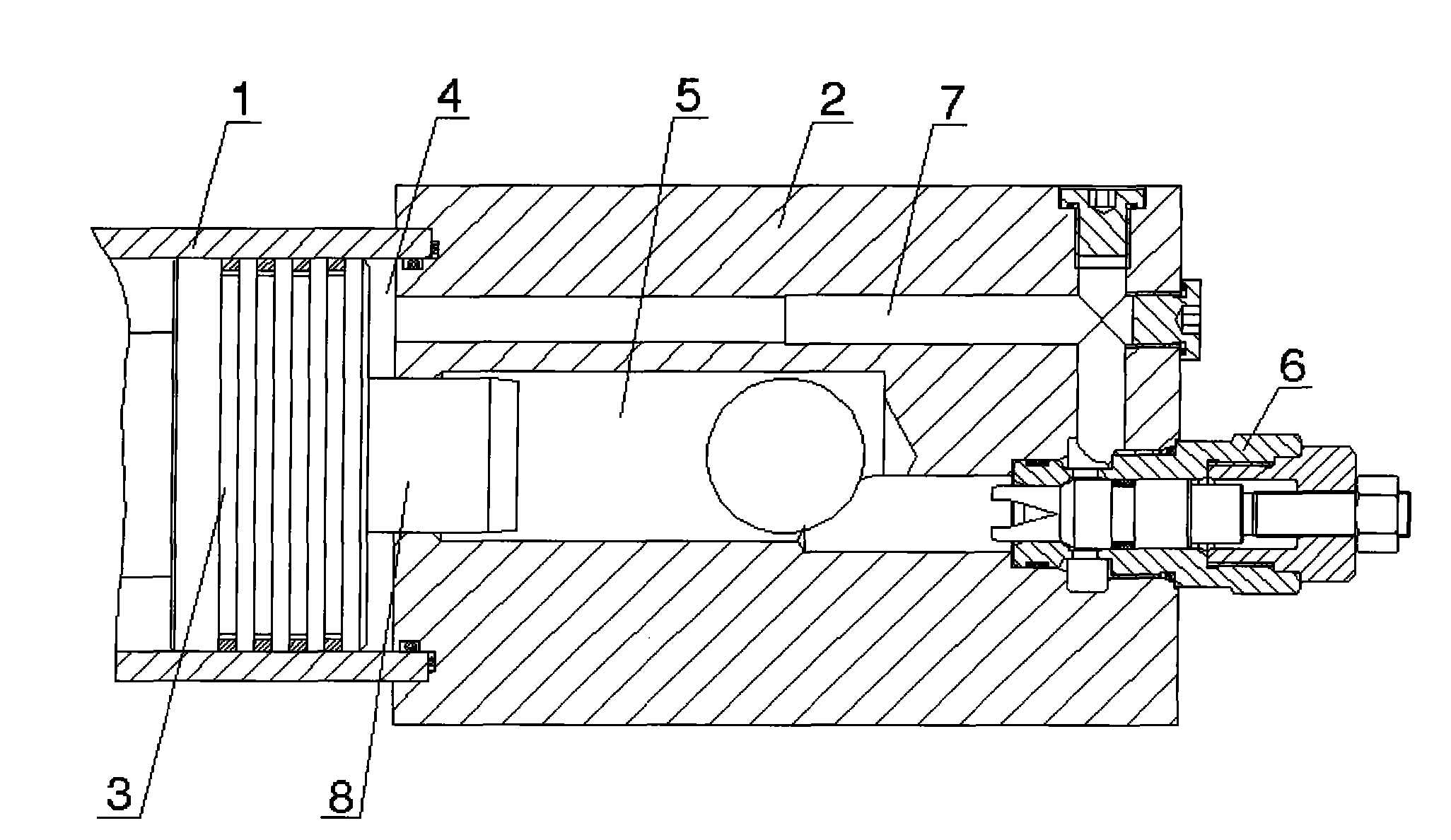

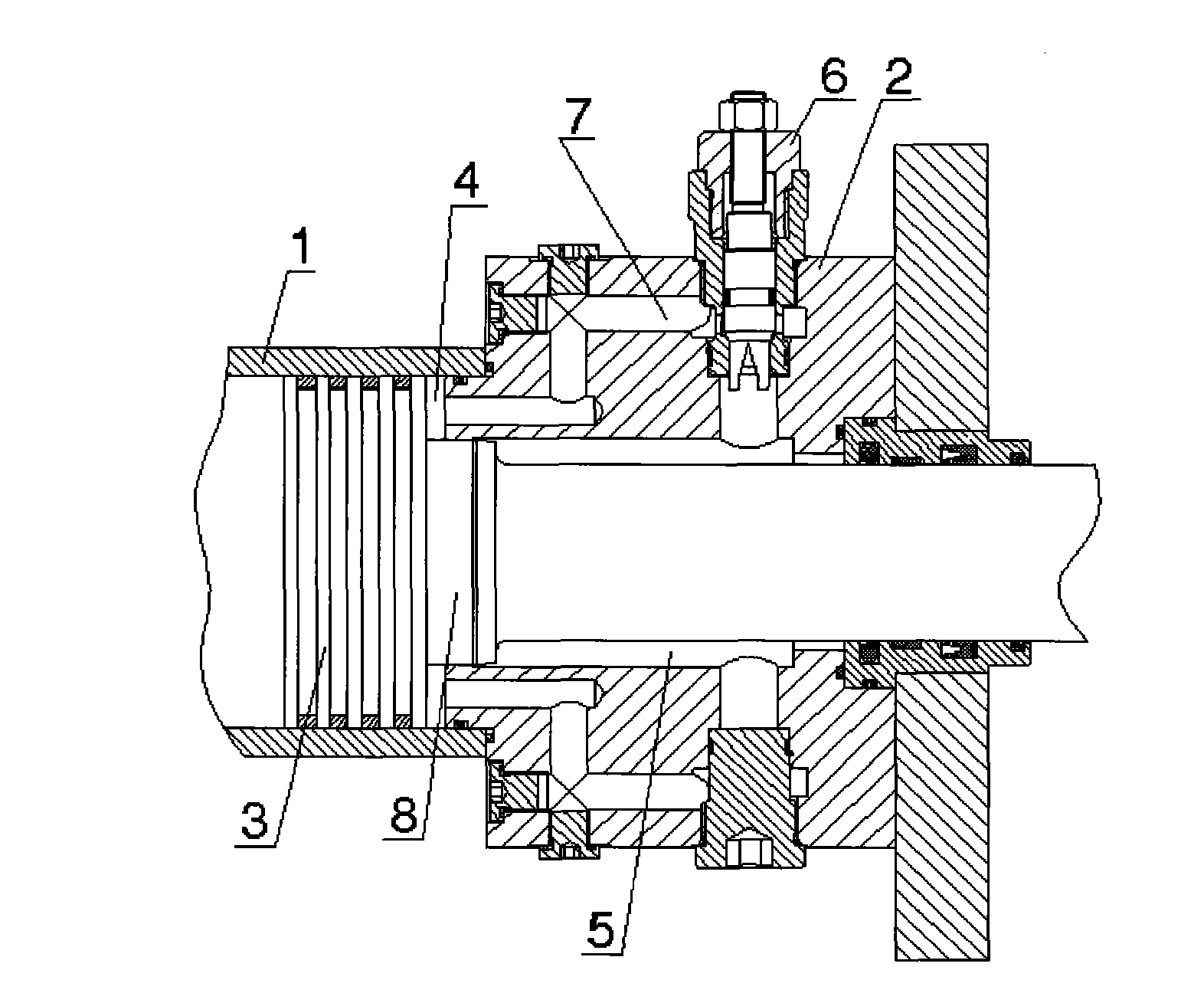

[0010] Such as Figure 1-Figure 2 As shown, a hydraulic cylinder provided by the embodiment of the present invention includes a cylinder 1, end caps 2 at the front and rear ends of the cylinder, and a piston 3 inside the cylinder. The piston 3 separates the cylinder 1 into two chambers at the front and rear Body 4, the end cover 2 corresponding to each cavity 4 is provided with an oil discharge chamber 5 communicating with the cavity 4, and the characteristic is that: the end cover 2 is provided with at least one adjustable buffer valve 6, The end cover 2 where each buffer valve 6 is located is provided with a channel 7 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com