Operation analysis apparatus

A technology of job analysis and job application in the direction of instrumentation, total factory control, textiles and papermaking, etc., to achieve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] (Overall structure of the embodiment of the invention)

[0060] Below, with reference to the accompanying drawings, based on Figure 1 to Figure 15 , the sewing machine work analysis system 100 including the work analysis device 101 according to the present invention will be described.

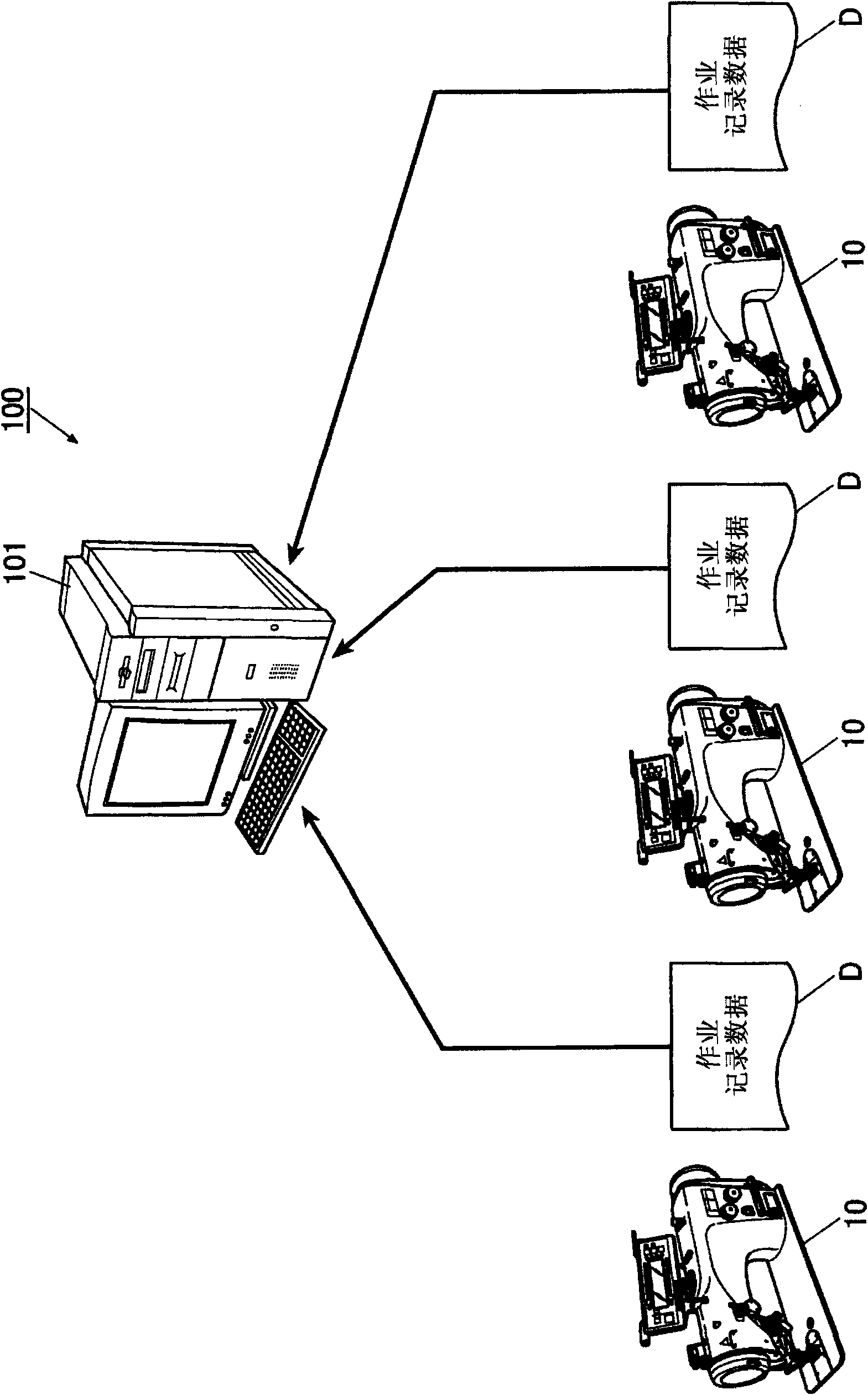

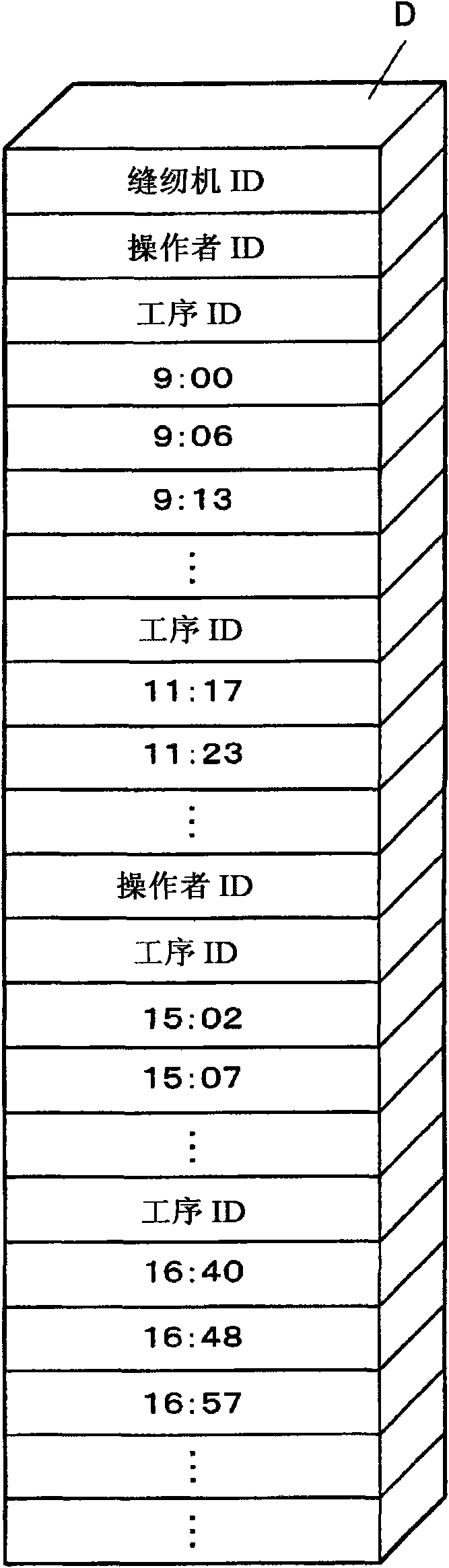

[0061] like figure 1 As shown, this job analysis system 100 has: a plurality of production management sewing machines 10; send / receive.

[0062] A personal computer or a workstation is used as the above-mentioned job analysis device 101 . In addition, wireless or wired communication means such as wireless LAN and wired LAN may be used for transmission / reception of job log data between job analysis device 101 and each production management sewing machine 10 .

[0063] (Production management sewing machine)

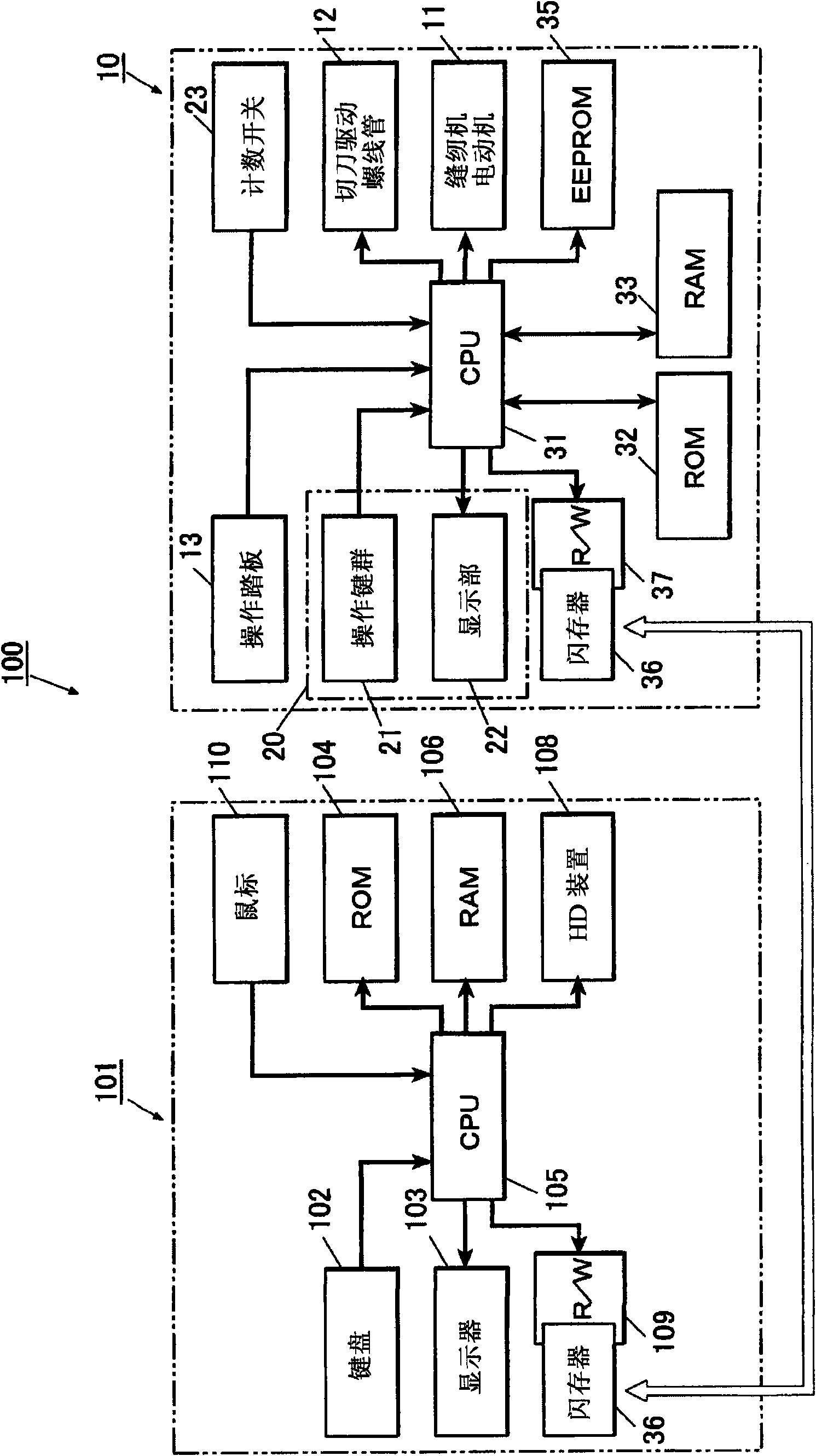

[0064] exist figure 2 Among them, each production control sewing machine 10 has: a sewing machine motor 11, which is a driving source for driving a needle bar holding a sewin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com