Test system for performance test of dust collector indicator

A test system and indicator technology, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of insufficient vacuum degree of the vacuum cleaner and the inability to quantitatively evaluate the indicator performance, etc., and achieve stable and reliable technical performance indicators. Save development time and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

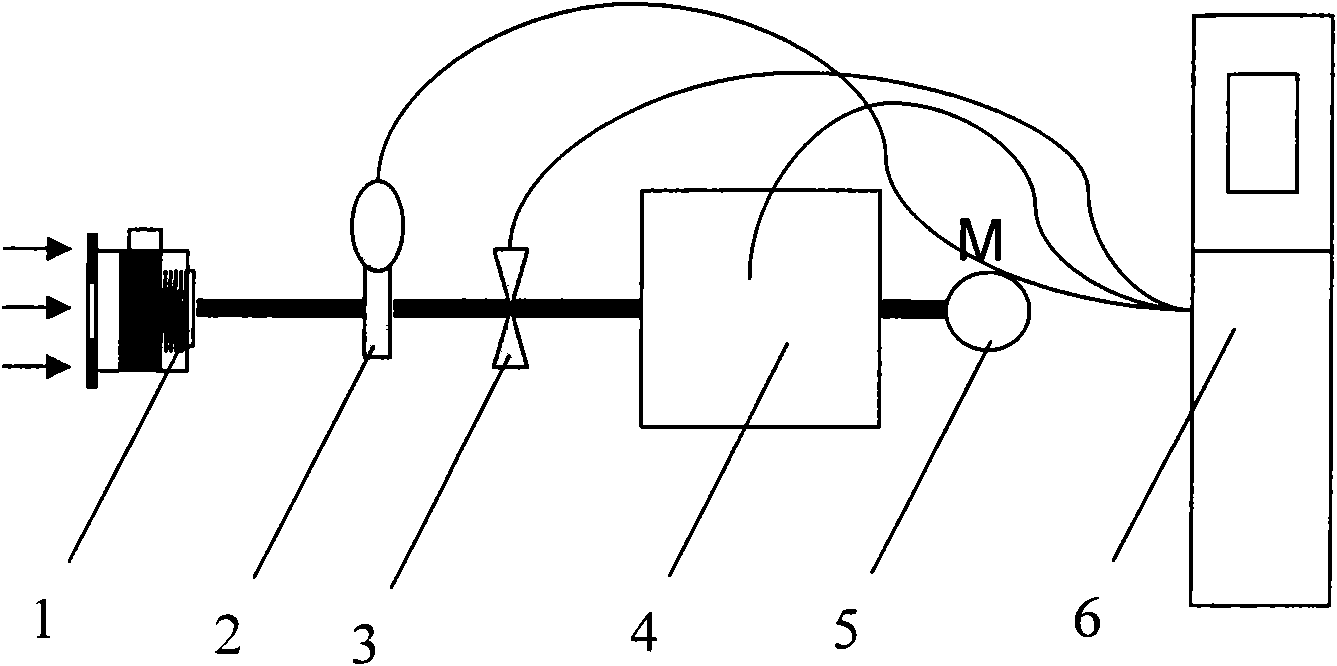

[0017] The structure of the test system used for the performance test of the vacuum cleaner indicator of the present invention will be described in conjunction with the accompanying drawings and embodiments.

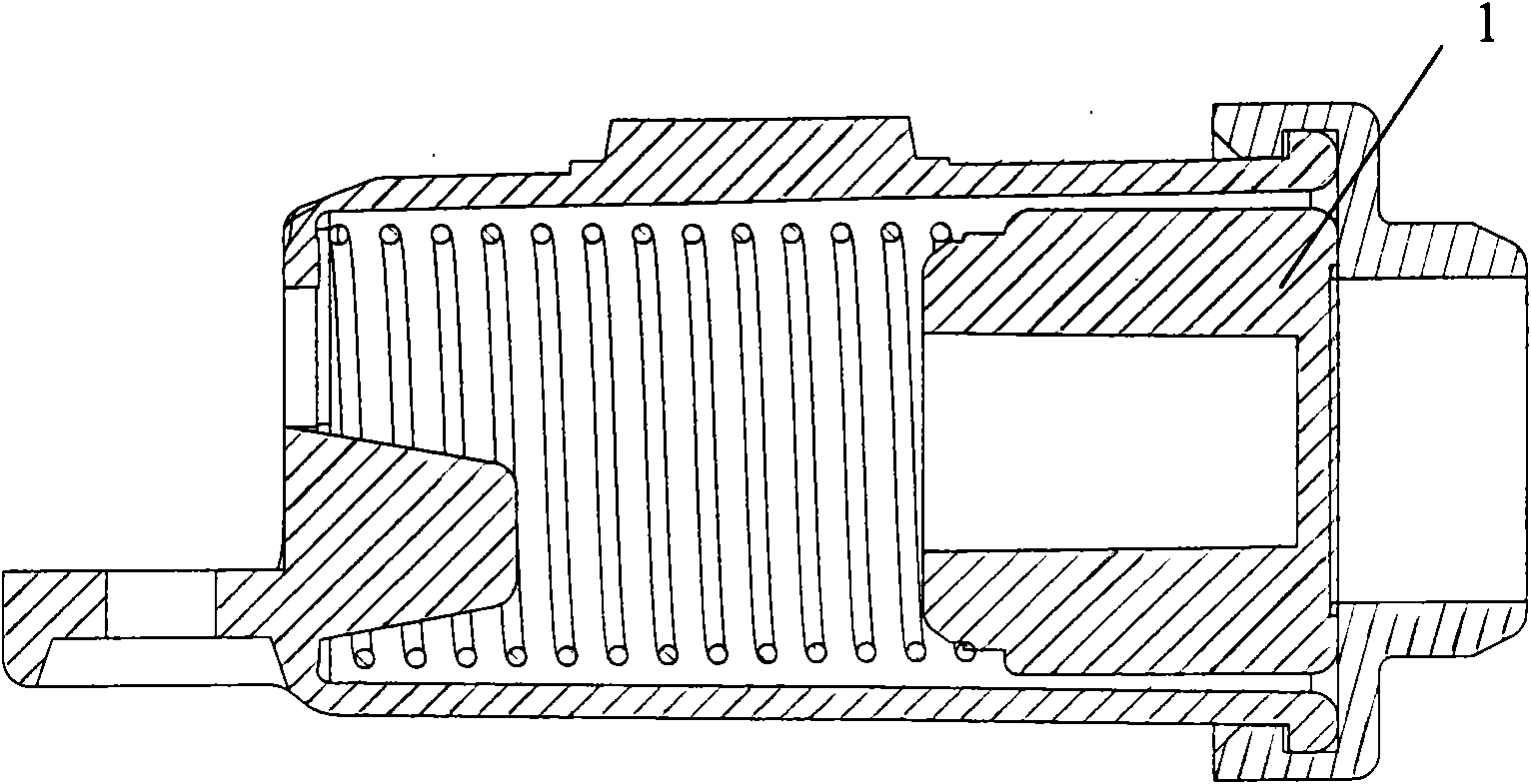

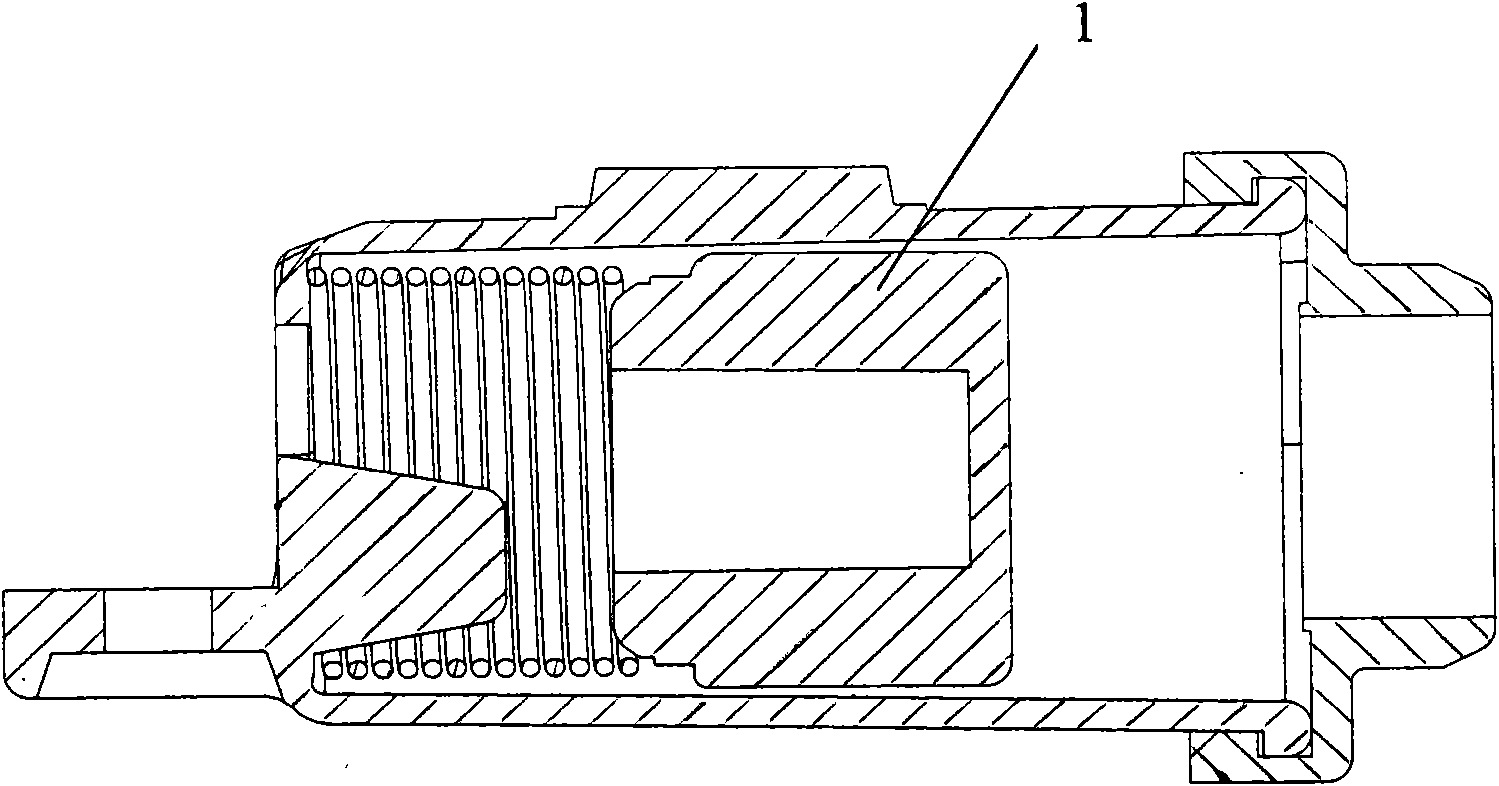

[0018] The structure of the test system used for the performance test of the vacuum cleaner indicator of the present invention is that the indicator body 1 in the indicator is electrically connected with a flow sensor 2, a control valve 3, and a vacuum pressure sensor 4 in turn, and the vacuum pressure sensor 4 is connected with a vacuum pump 5 ; The flow sensor 2, the control valve 3, and the vacuum pressure sensor 4 are electrically connected to the computer 6 for signal transmission and data collection. The measurement range of the flow sensor 2 is 0-40L / S; the measurement range of the vacuum pressure sensor 4 is 0 to -30KPa.

[0019] The vacuum cleaner indicator performance testing system of the present invention can quantitatively evaluate the performance of the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com