Improved holographic dynamic balancing method of high-speed main shaft

A high-speed spindle and holographic technology, applied in the field of holographic dynamic balance, can solve the problems of monitoring false alarms and wrong diagnosis conclusions, and achieve the effect of improving efficiency, improving accuracy and improving separation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

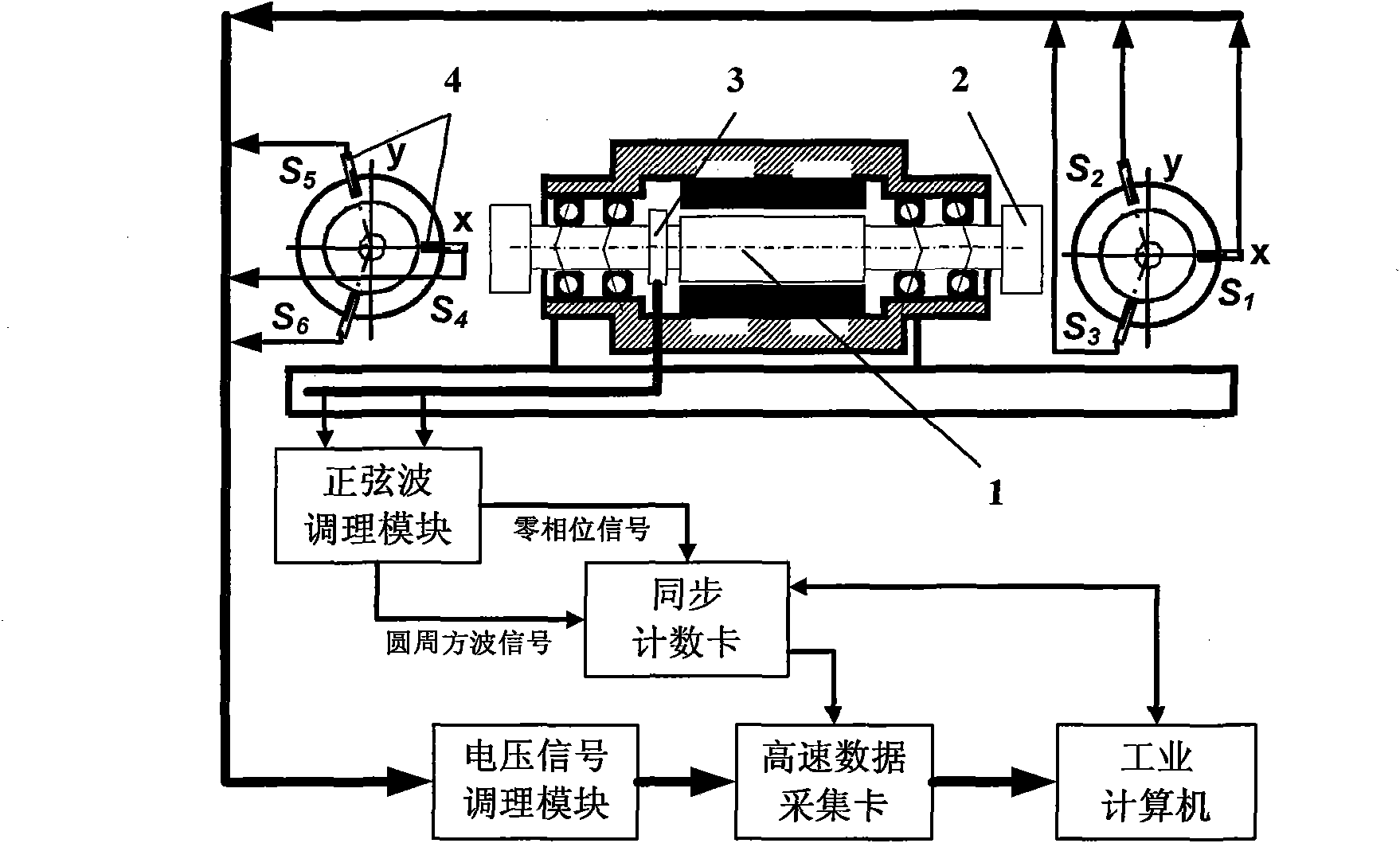

[0027] In order to understand the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings.

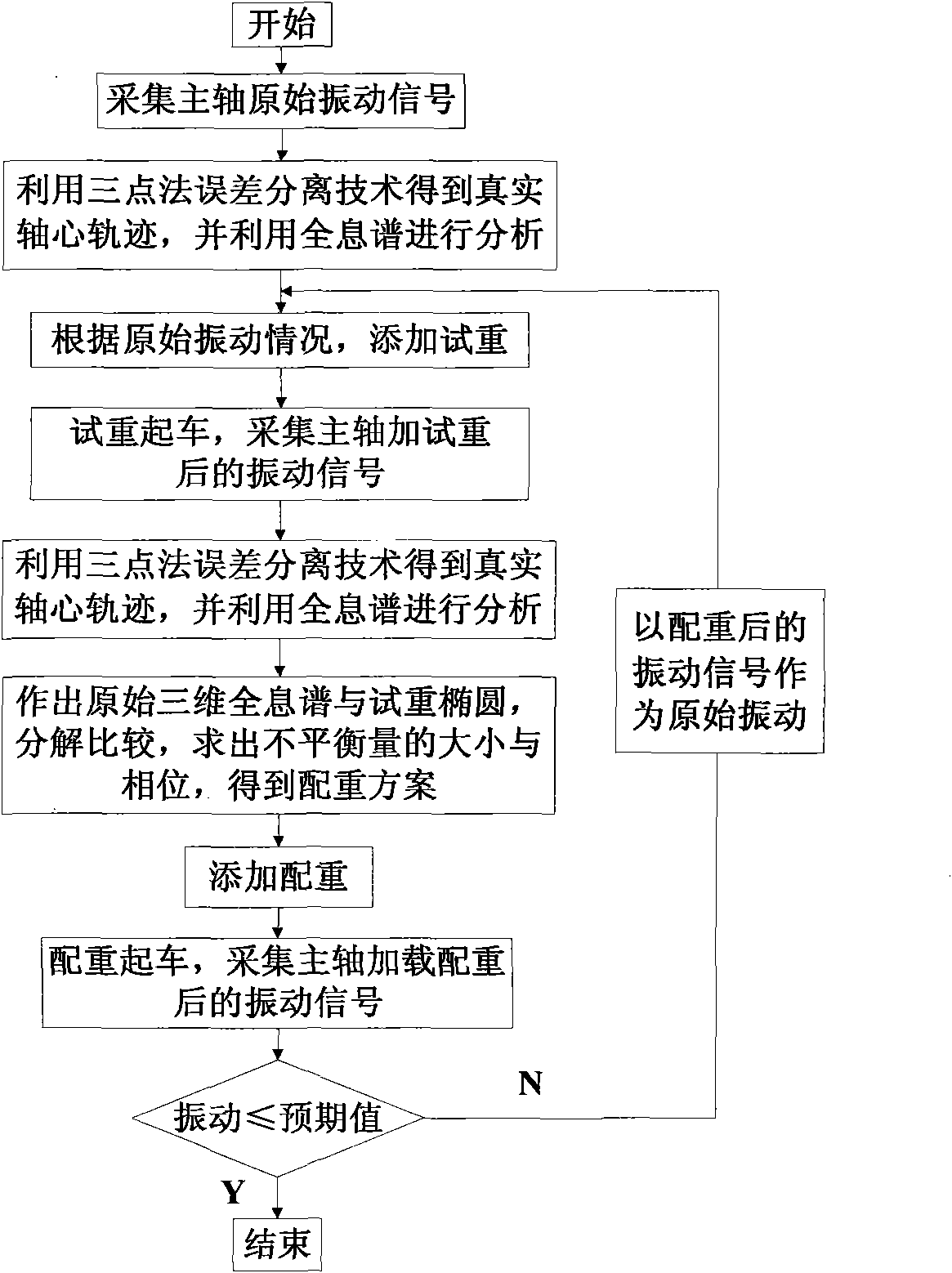

[0028] figure 1 Shown, the concrete balancing step of the inventive method is:

[0029] Step 1, collecting the original vibration signals of the two test sections at the balanced speed of the faulty spindle;

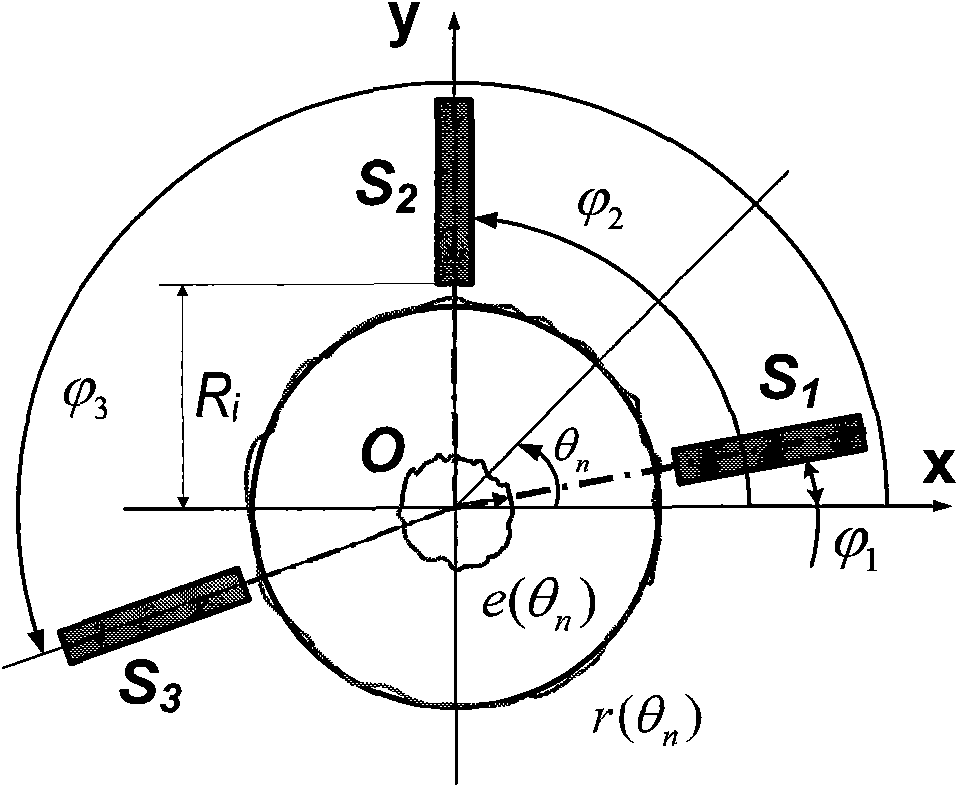

[0030] Step 2, according to the error separation technology of the three-point method, the roundness error separation is performed on the vibration signals of the two sections at both ends of the main shaft, and the actual axis center track after the roundness error is eliminated is obtained;

[0031] Step 3, according to the information fusion technology, obtain the power frequency two-dimensional hologram of each test section for the x and y components of the axis trajectory obtained in step 2; judge whether the main vibration main fault source is unbalanced; obtain each test The initial pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com