Beta-hydroxy fatty acid collecting agent for positive floatation of iron ore and application thereof

A technology of hydroxy fatty acid and fatty acid, which is applied in flotation, solid separation, etc., can solve the problems of weak effect and achieve the effect of increasing the collection capacity and improving the grade of concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

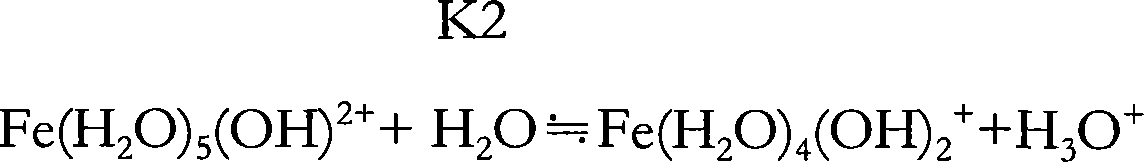

Method used

Image

Examples

Embodiment 1

[0034] The weight percentages of various components of the collector are 85% of β-hydroxy fatty acids, 2% of alcohols, 1% of inorganic salts, and the rest of water; wherein the composition of various β-hydroxy fatty acids accounts for 85% of the total β-hydroxy fatty acids The weight percentages are as follows:

[0035] Beta-Hydroxytridecanoic Fatty Acid 11%, Beta-Hydroxytetradecanoic Acid 20%, Beta-Hydroxypentadecanoic Acid 25%, Beta-Hydroxyhexadecanoic Acid -Hydroxy octadecanoic acid 10%, β-hydroxy fatty acid with a carbon chain below thirteen fatty acid is 2%, and β-hydroxy fatty acid with a carbon chain above octadecanoic acid is 1%

Embodiment 2

[0037] The weight percentages of various components of the collector are 87% of β-hydroxy fatty acids, 2% of alcohols, 1% of inorganic salts, and the rest of water; wherein the composition of various β-hydroxy fatty acids accounts for 87% of the total β-hydroxy fatty acids The weight percentages are as follows:

[0038] β-Hydroxytridecanoic acid is 12%, β-hydroxytetradecanoic acid is 21%, β-hydroxypentadecanoic acid is 22%, β-hydroxyhexadecanoic acid is 20%, β-hydroxyheptadeca fatty acid is 11%, -Hydroxy octadecanoic acid 12%, β-hydroxy fatty acid with a carbon chain below thirteen fatty acid is 1%, and β-hydroxy fatty acid with a carbon chain above octadecanoic acid is 1%.

Embodiment 3

[0040] The application of the β-hydroxy fatty acid collector of embodiment 2, consumption is 300 grams / ton dry ore amount, and the percentage by weight of ore pulp is 38%, and the pH of ore pulp is 10.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com