Method for processing large workpiece boring hole by using drilling machine

A technology for mechanical processing and large workpieces, which is used in drilling dies for workpieces, metal processing equipment, reaming devices, etc. Simple, low processing cost, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

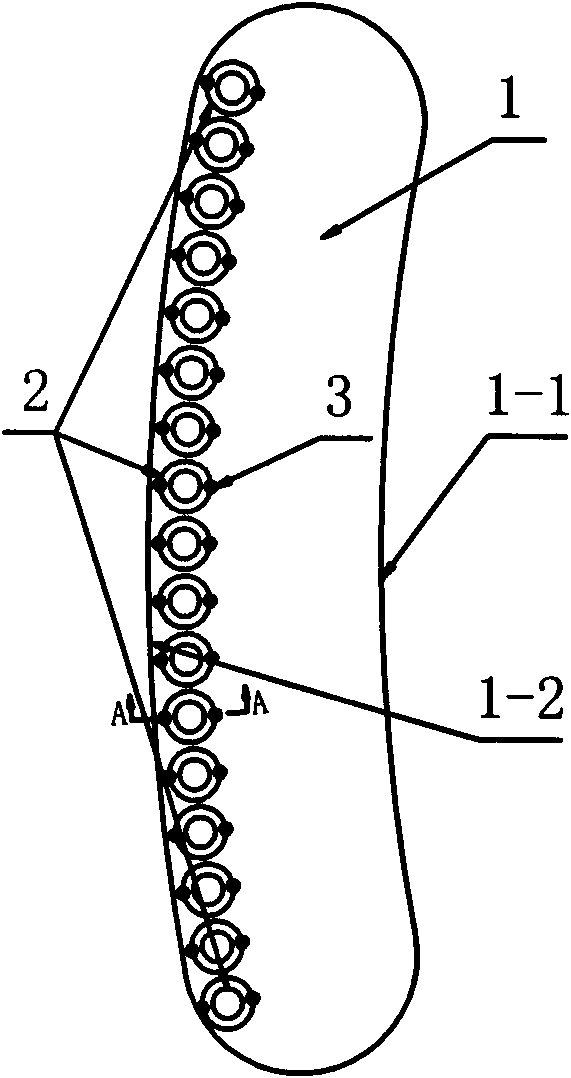

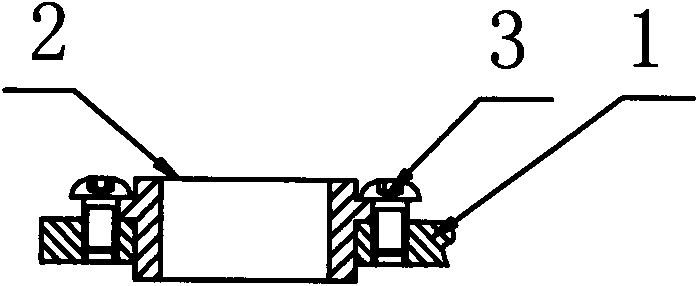

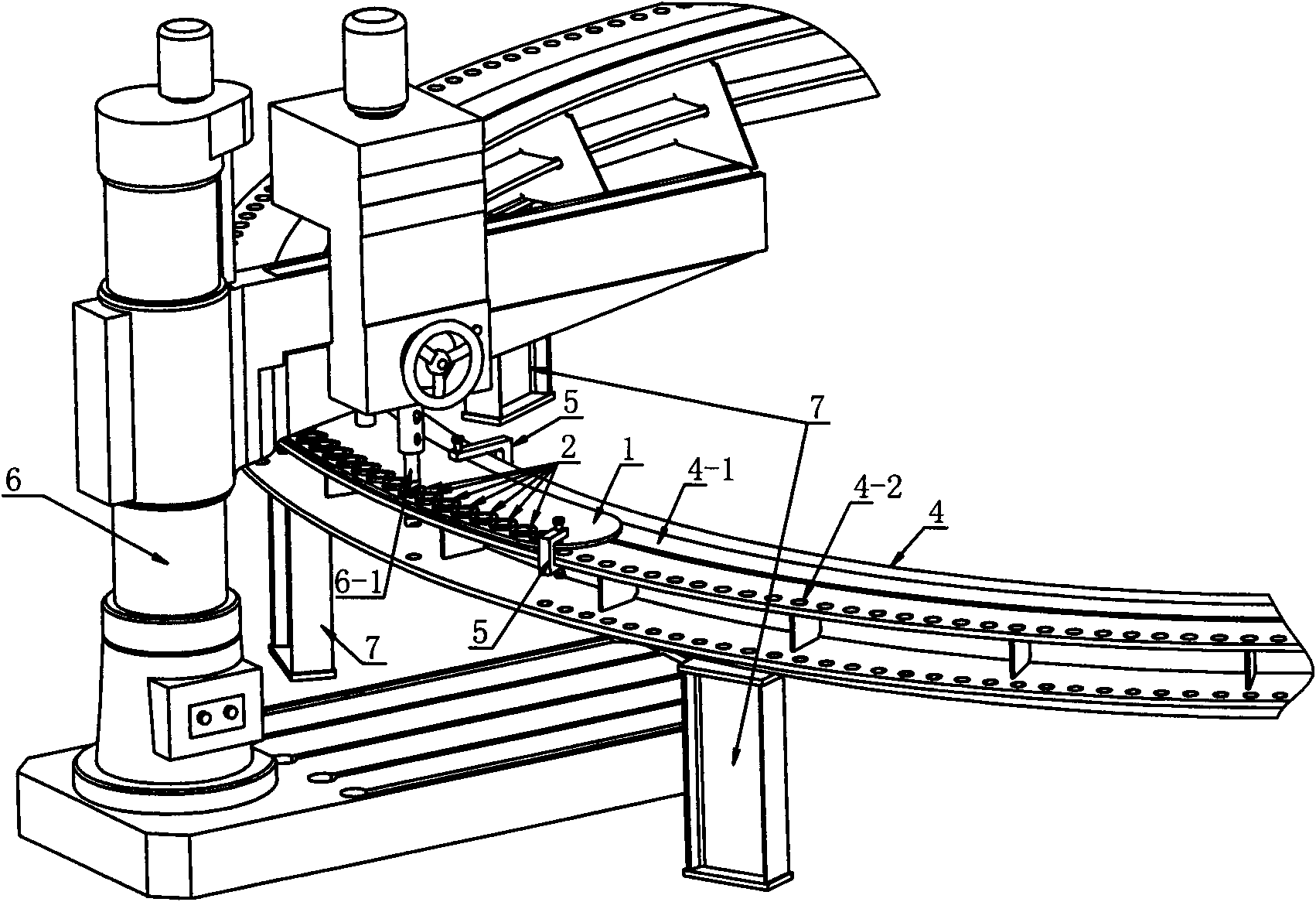

[0024] Such as figure 1 and figure 2 As shown, it is the drilling and reaming sleeve template used in the present invention, including template 1. In this embodiment, the processed workpiece is a stacker-reclaimer rotary disk with a diameter of 7.5m, and the radial drilling machine is used to pass the indexing of the drilling and reaming sleeve template on the rotary disk. 248 sets of holes with a diameter of Φ50mm are processed on the end surface of the circumference. The shape of the template and the upper holes are completed by laser cutting. The template is arc-shaped, and the diameter of the outer arc 1-2 is equal to the diameter of the outermost circle of the turntable , the diameter of the inner arc 1-1 of the arc template is equal to the diameter of the inner circle of the walking track surface 4-1 on the rotary disk 4, which is conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com