Filter for a fabric dyeing machine

A filter and cloth dyeing machine technology, applied in the filter field, can solve the problems of reducing the efficiency and productivity of the cloth dyeing machine, time-consuming filter cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention proposes a self-cleaning filter used in a cloth dyeing machine to save or reduce the need for manual filter cleaning.

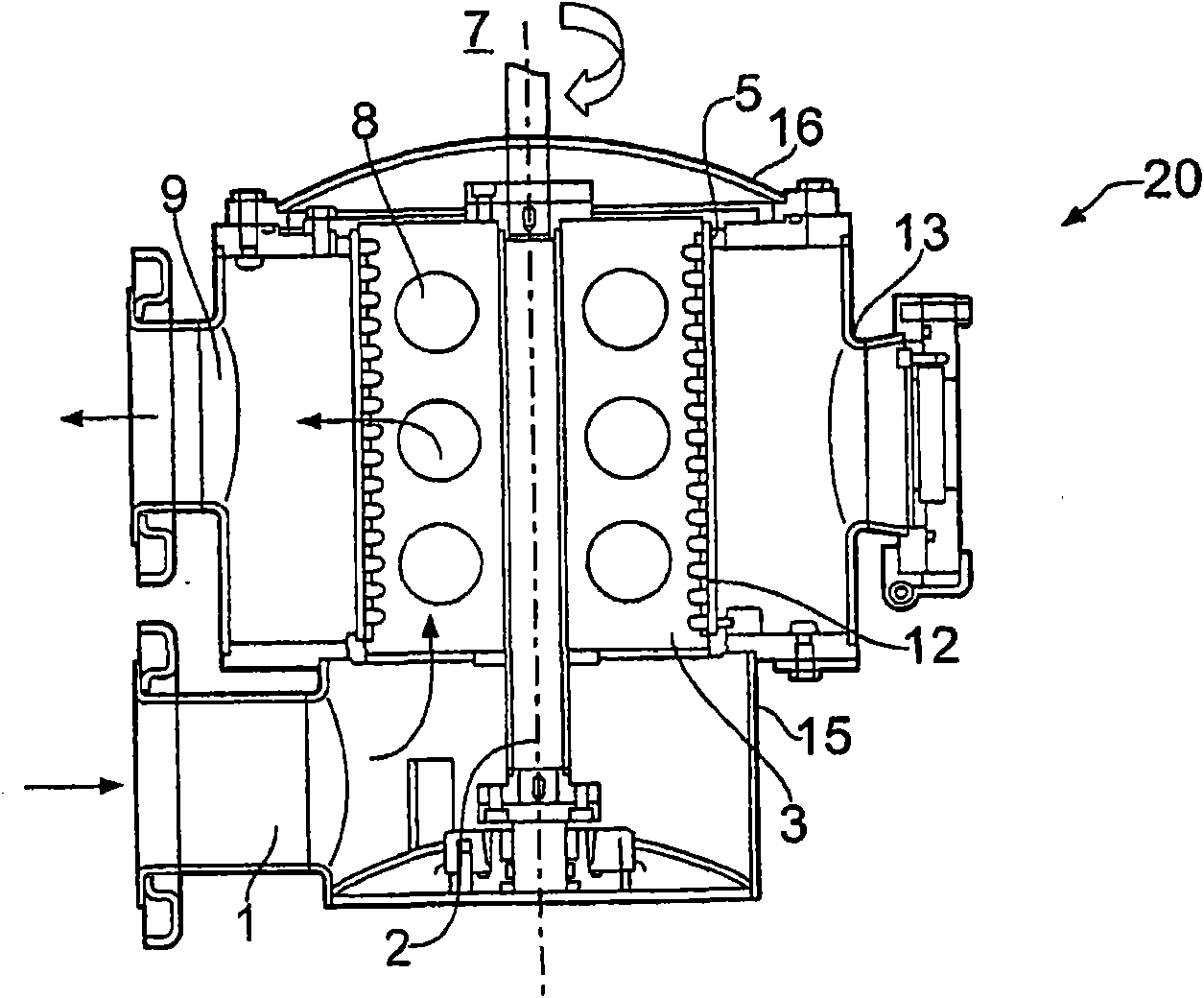

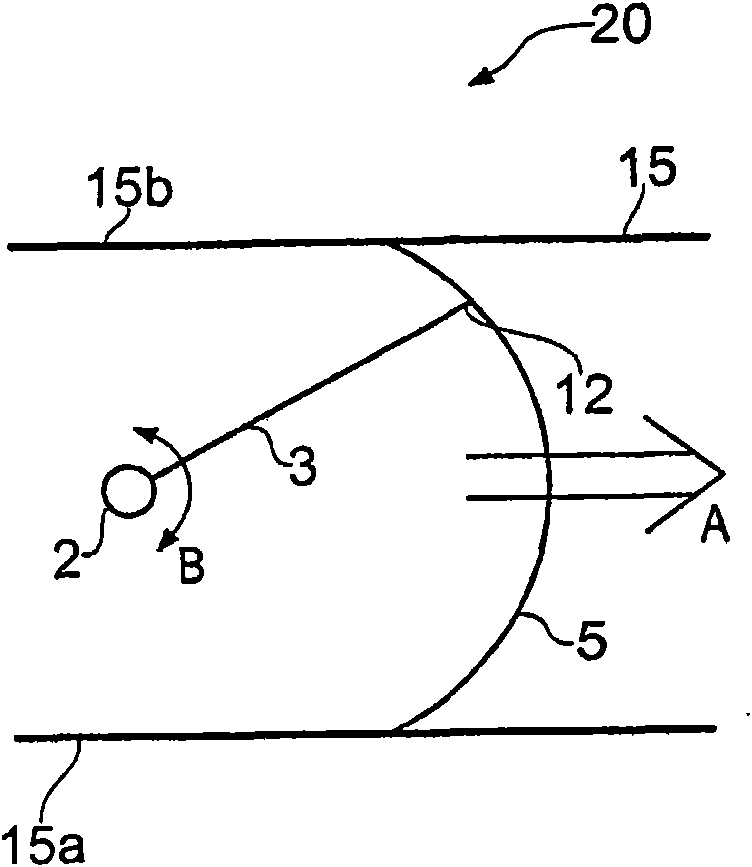

[0020] figure 1 A cutaway side view of a filter according to one embodiment of the invention is shown. The filter 20 comprises a hollow container 15 which accommodates various components which will be described later. The container 15 is generally cylindrical and is provided with a fluid inlet 1 at the lower part of its side wall and a fluid outlet 9 at the upper part of its side wall. The inlet 2 and the outlet 9 are arranged to be connected to the pipes defining the flow path of the dye liquor in the dyeing machine. Thus, the dye liquor from the dyeing machine can enter the inlet 1, pass upwards through the central part of the container 15, and return to the dyeing machine via the outlet 9, as figure 1 indicated by the arrow in .

[0021] A rotatable shaft 2 is mounted vertically through the center of the container 15 . Sui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com