Automatic puer tea stacking and fermenting device

A technology of automatic stacking and fermentation equipment, which is applied in tea treatment before extraction, etc. It can solve the problems of unstable tea fermentation quality, fear of exporting fermented tea, and difficult control, so as to improve air permeability and drainage characteristics, and prevent rot and growth. Insect phenomenon, the effect of eliminating direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

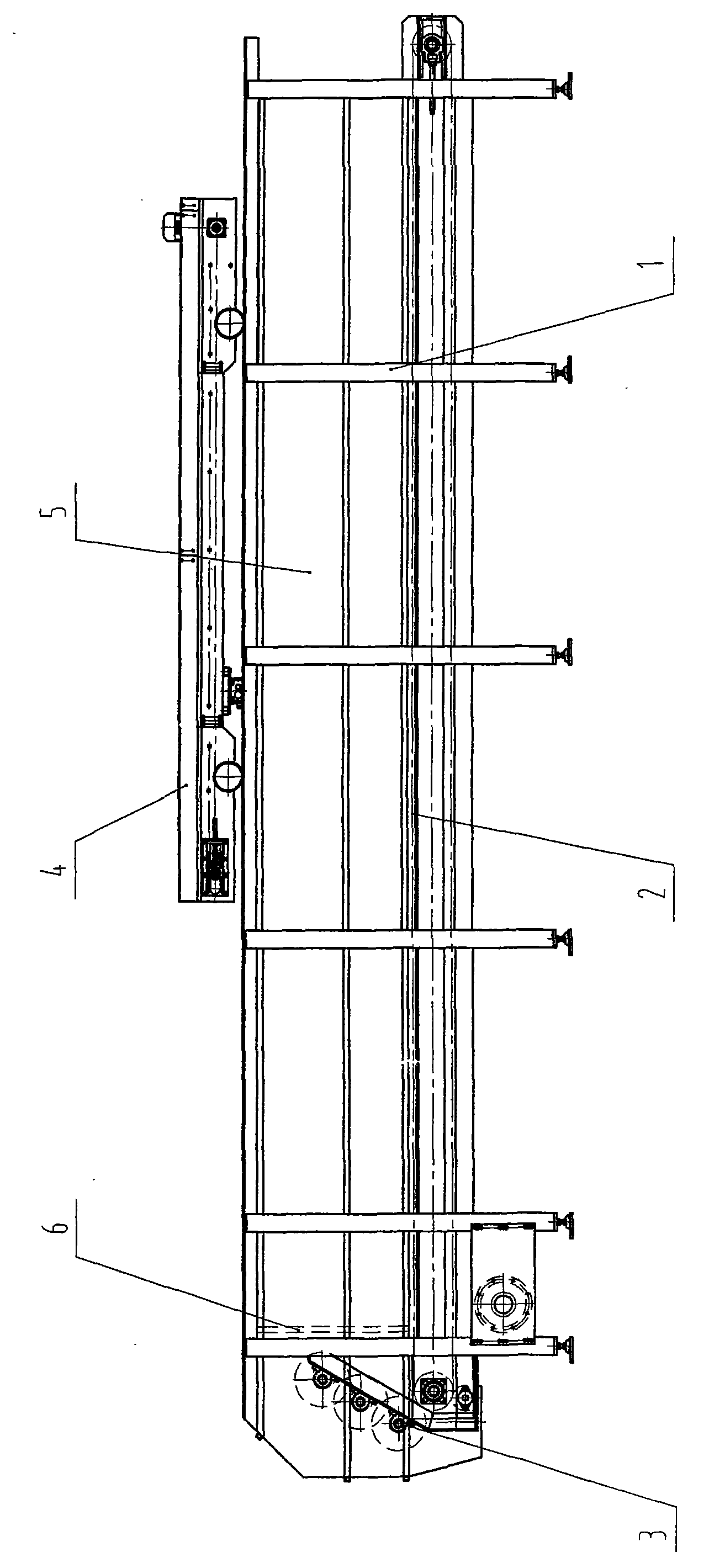

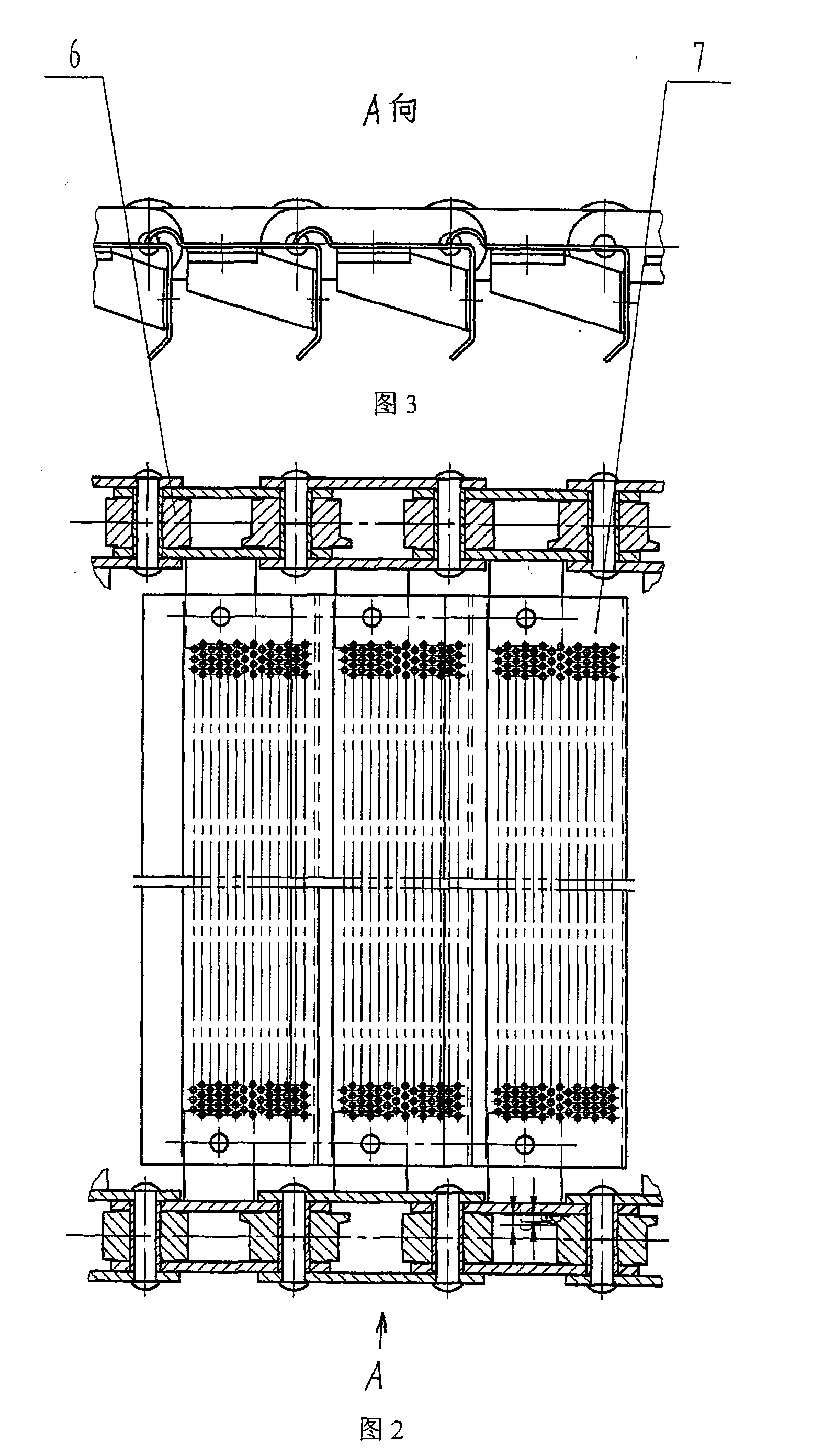

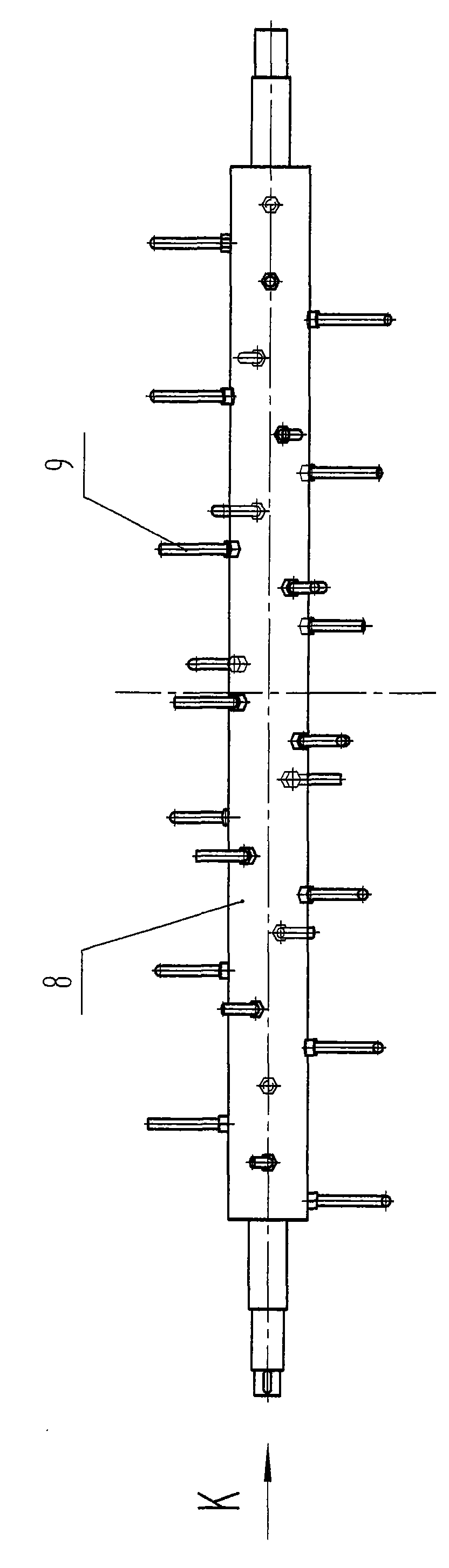

[0025] Such as figure 1 As shown, the automatic stacking fermentation equipment of the present invention is composed of a cabinet body 1, a bottom mesh conveying mechanism 2 in the cabinet body, a raking roller 3 at the front end of the cabinet body, and a reciprocating material spreading conveyor 4 on the top of the cabinet body. The bottom mesh conveying mechanism is composed of multiple combined stainless steel punching mesh driven by the conveyor chain 7 on both sides of the bottom mesh. The stainless steel punching mesh is a steel plate bent into an L shape, and the side in contact with the tea is punched. It is used to support the tea leaves to ensure the ventilation and drainage of the tea leaves. The other side plays the role of reinforcement and support. Driven by the motor, the perforated mesh plate can carry the tea leaves forward. After the stacking and fermentation, the stainless steel mesh plate can transport the tea leaves Automatically send out the device. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com