Undisturbed switching method for operating modes of multi-stage pump station and energy dissipater thereof

A technology of non-disturbance switching and energy dissipation devices, which is applied in pump control, machine/engine, liquid variable capacity machinery, etc., and can solve problems such as parking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically described below in conjunction with the accompanying drawings.

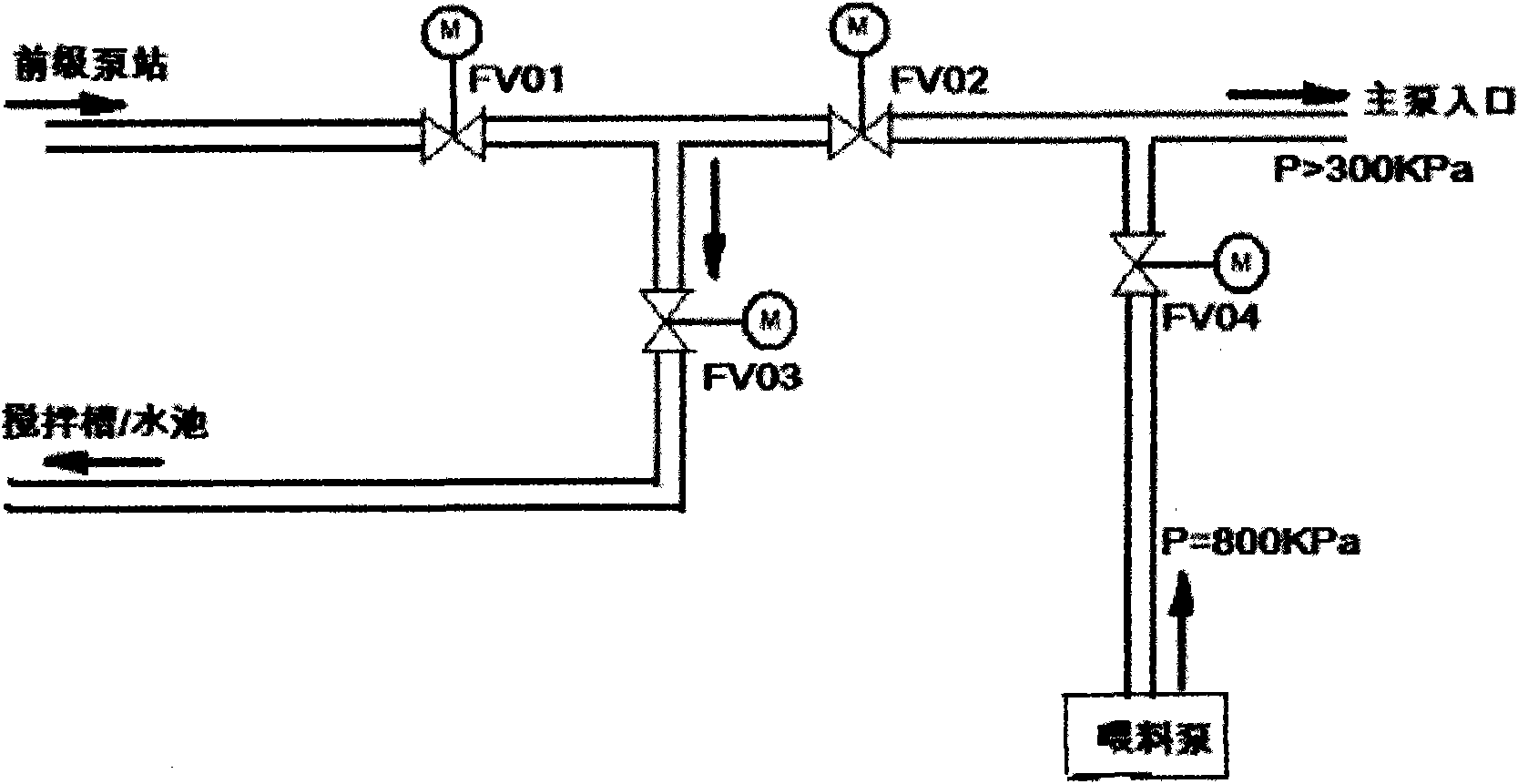

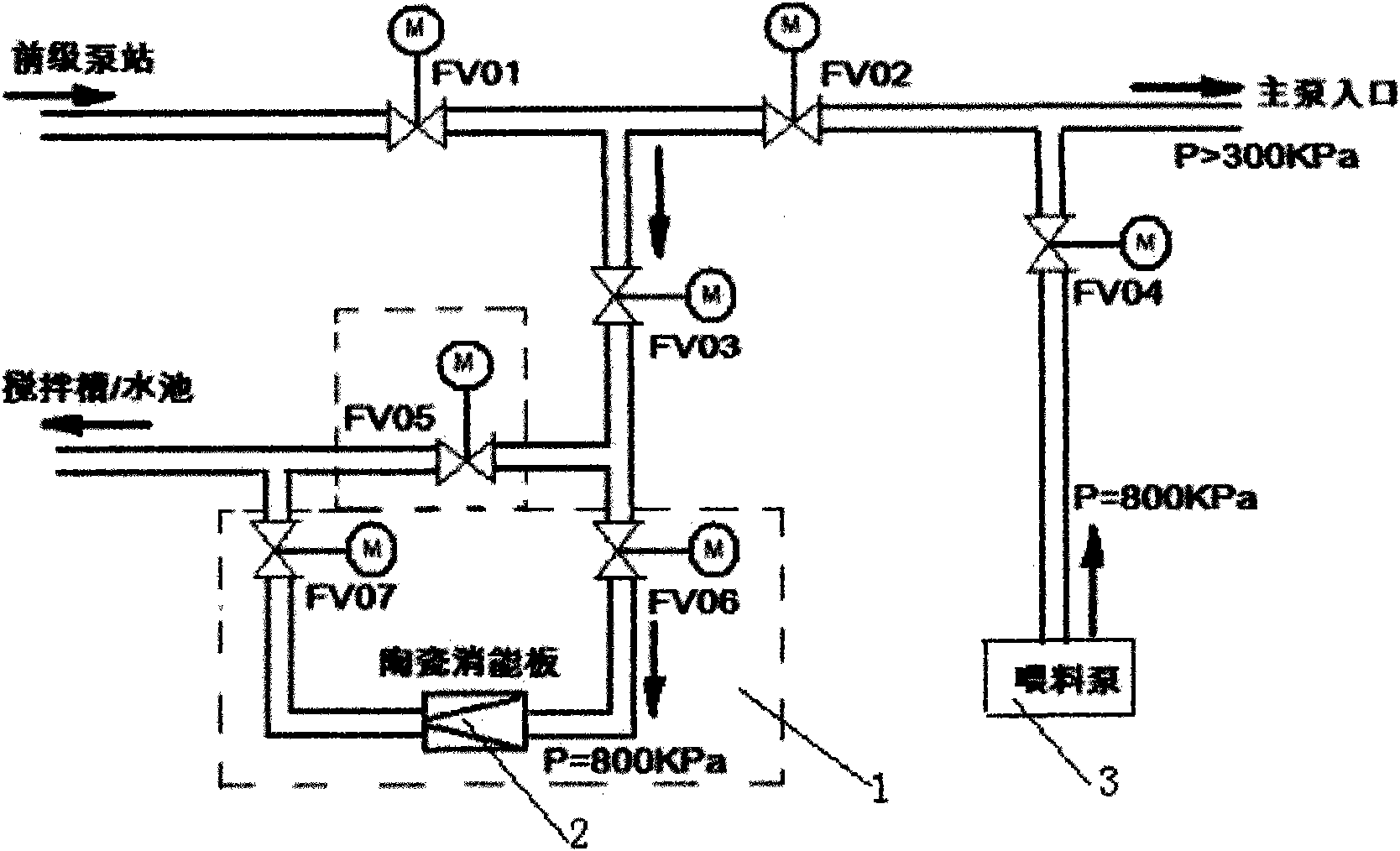

[0016] Such as figure 2 As shown, a first ball valve FV01 and a second ball valve FV02 are set between the front pumping station and the main pump inlet, a third ball valve FV03 is set between the output end of the first ball valve FV01 and the stirring tank / pool, and the second A feeding pump ball valve FV04 is provided between the output end of the ball valve FV02 and the feeding pump. In the present invention, a set of energy dissipation device 1 is added to the rear end of the ball valve FV03. As shown in the dotted line box in the figure, the energy dissipation device 1 includes ceramic Energy board 2, input port ball valve FV06 and output port ball valve FV07. The energy dissipation plate 2 is used to equalize the pressure at both ends of the energy dissipation plate 2 . At the same time, a control ball valve FV05 is added between the ball valve FV03 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com