Method for dyeing vivid fluorescent green on cotton knitwear

A fluorescent green, knitwear technology, applied in the field of bright fluorescent green dyeing of cotton knitwear, can solve problems such as color migration, quality does not meet basic requirements, color stains, etc.

Inactive Publication Date: 2011-01-05

ZHEJIANG YINHE PRINTING & DYEING

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After dyeing and washing with this formula, color fixing agent must be used to fix the color. After dehydration, the gray fabric dyed with direct green blue GL will migrate the color before drying, resulting in color stains.

After color fixation, the light fastness of 7GFF fluorescent yellow is basically lost, and the quality does not meet the basic requirements of the industry. However, replacing 7GFF fluorescent yellow with other bright yellows cannot achieve the vividness of green, so direct dyes cannot be used. method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

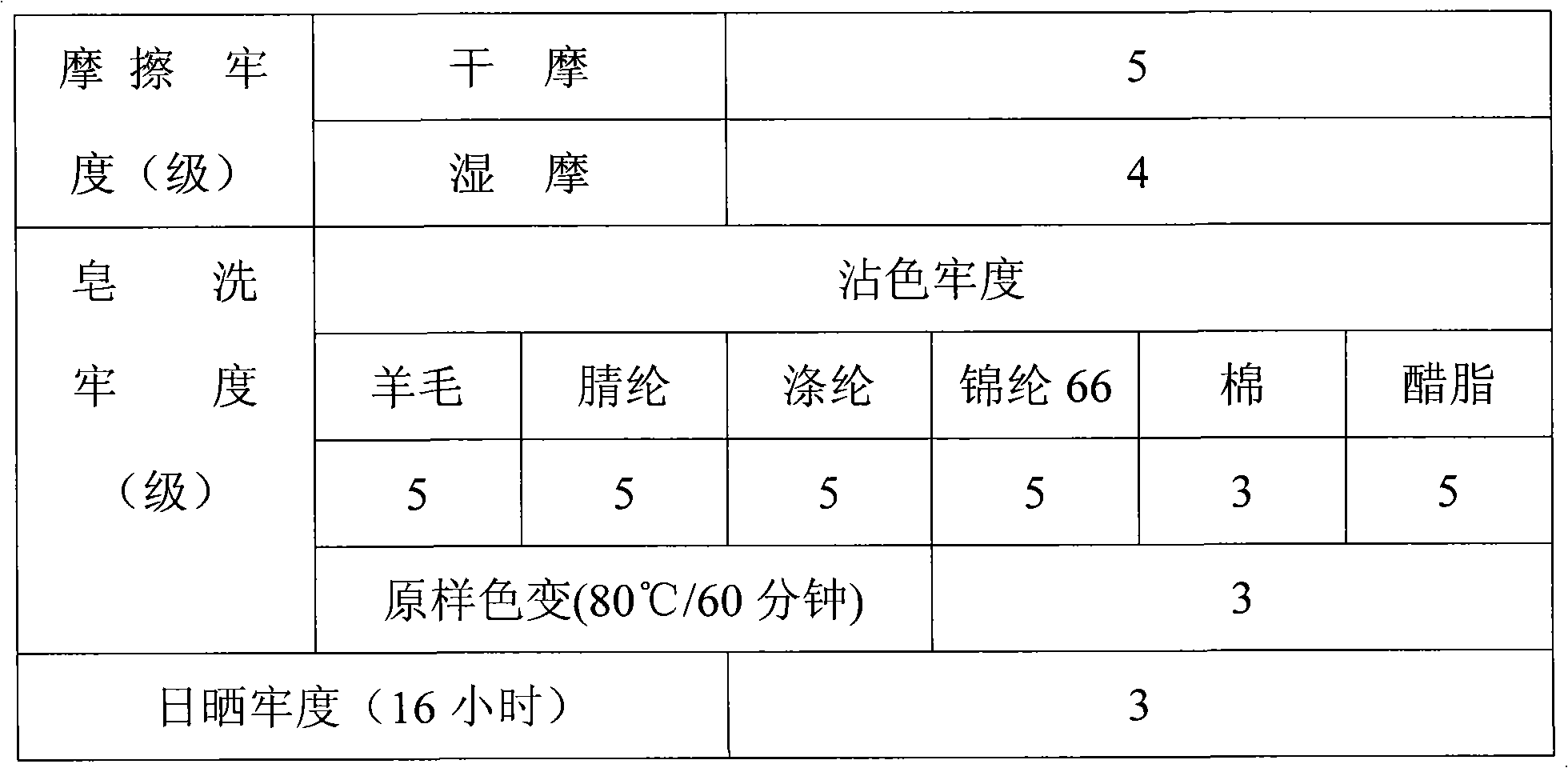

The invention relates to a method for dyeing cotton knitwear, in particular to a method for dyeing fluorescent green on cotton knitwear. The method comprises the following steps: 1) pretreating grey cloth; 2) placing the grey cloth and eightfold weight of water into a dye vat; 3) heating the grey cloth and the water to a temperature of 60 DEG C, adding reactive emerald blue MZ-HGN, 7GFF fluorescent yellow and salt into the dye vat in sequence to reserve the temperature for 30 minutes; 4) continuously heating the mixture to a temperature of 80 DEG C, and gradually adding calcined soda for fixation, and reserving the temperature for 30minutes; 5) continuously heating the mixture to a temperature of 100 DEG C, and reserving the temperature for 15 minutes; 6) comparing the grey cloth with a sample, cooling the grey cloth to a temperature of 70 DEG C, and removing dye liquor; 7) washing the grey cloth with water twice after the steps; 8) washing the water washed grey cloth with soap once at a temperature of 90 DEG C; 9) washing the grey cloth which is washed by the soap for 2 or 3 times with water; 10) carrying out softening treatment on the water washed grey cloth at 40 DEG C, reserving the temperature for 15 minutes and taking the grey cloth out of the dye vat; 11) dehydrating the grey cloth; 12) drying the grey cloth; 13) shaping the grey cloth. The cloth dyed through the methodnot only can meet the requirement of clients on color brightness, but also achieves the corresponding quality index.

Description

Method for Dyeing Bright Fluorescent Green on Cotton Knitted Fabrics technical field The invention relates to a method for dyeing cotton knitwear, in particular to a method for dyeing bright fluorescent green cotton knitwear. Background technique Cotton knitted gray fabric sample dyeing processing, customers provide sample fabrics, some provide color samples are other items, such as samples made of fluorescent paint, and the customer's dyeing requirement for knitted gray fabric is not fluorescent paint or the like, but the color is very bright , the conventional dyeing formula process can't meet the requirements at all. Under normal circumstances, the bright green dyeing of cotton knitwear is usually dyed with direct dyes or reactive dyes, according to the dyeing formula of direct dyes (according to the percentage of gray cloth weight): Direct Green Blue GL: 0.8%, 7GFF Fluorescent Yellow: 0.1%, Salt: 5% After dyeing and washing with this formula, it must be fixed with...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06P3/62D06P3/66

Inventor 陈和军

Owner ZHEJIANG YINHE PRINTING & DYEING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com