Method for splicing high-bearing-capacity steel cable

A bearing capacity, steel cable technology, applied in textile cables, end bundling, load hanging components, etc., can solve problems such as bearing capacity limitation, inability to meet market needs, etc., and achieve the effect of a simple insertion method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

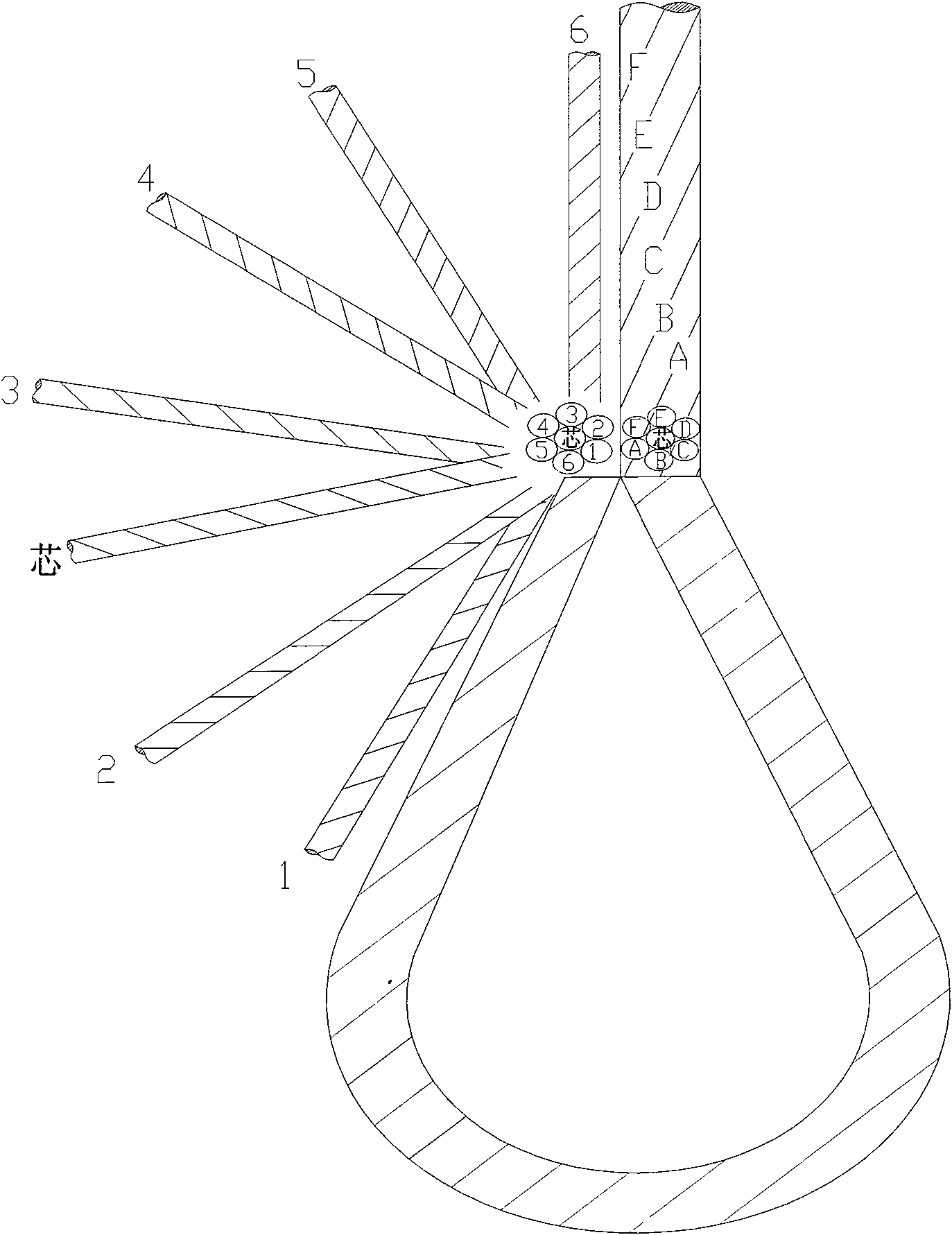

[0042] Figure 3-Figure 8 It shows the first group of inserting steps from sequence 1 to sequence 7. 10 in the figure is the guide needle used for inserting. First, use the guide needle to open the gap to be inserted, and then connect each strand of steel wire rope according to the sequence table. 1. Carry out inserting, one by one. After the first group inserting is completed, each group will insert according to Table 2 in the sequence table. After reaching the number of inserting needles, use a thin steel wire rope Pass through the ring 31 and bind on the steel cable body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com