Nozzle

A nozzle and nozzle body technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of excessive atomization of nozzles, achieve the effects of reducing atomization, proper proportion, and ensuring the amount of liquid ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will now be described in detail in conjunction with the accompanying drawings.

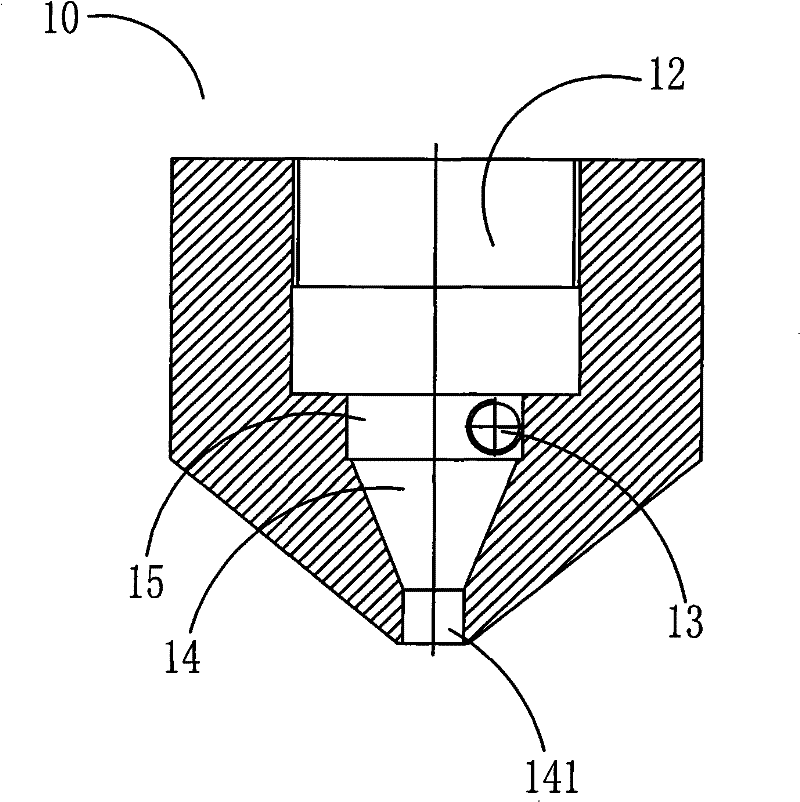

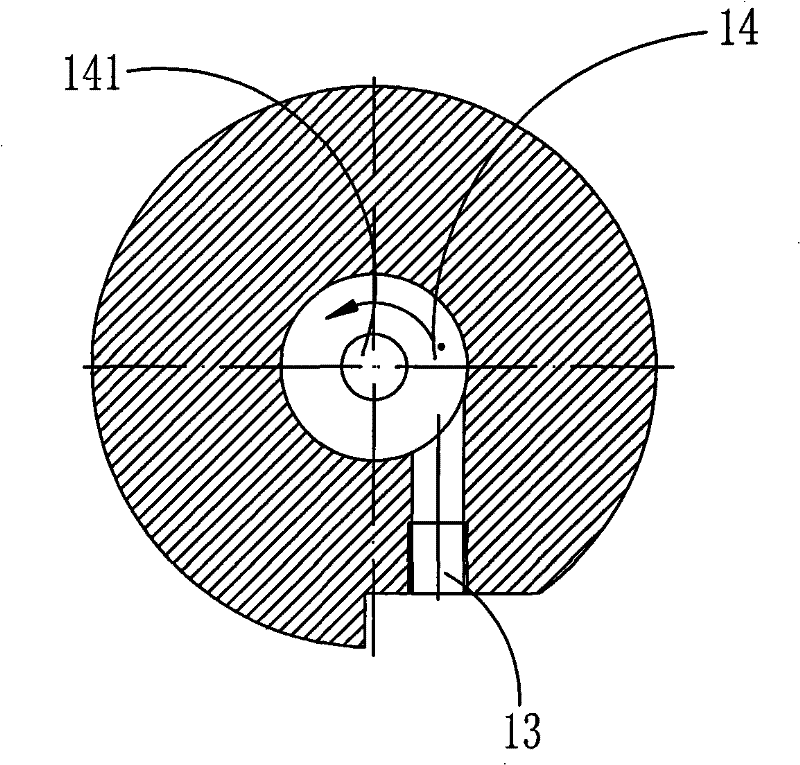

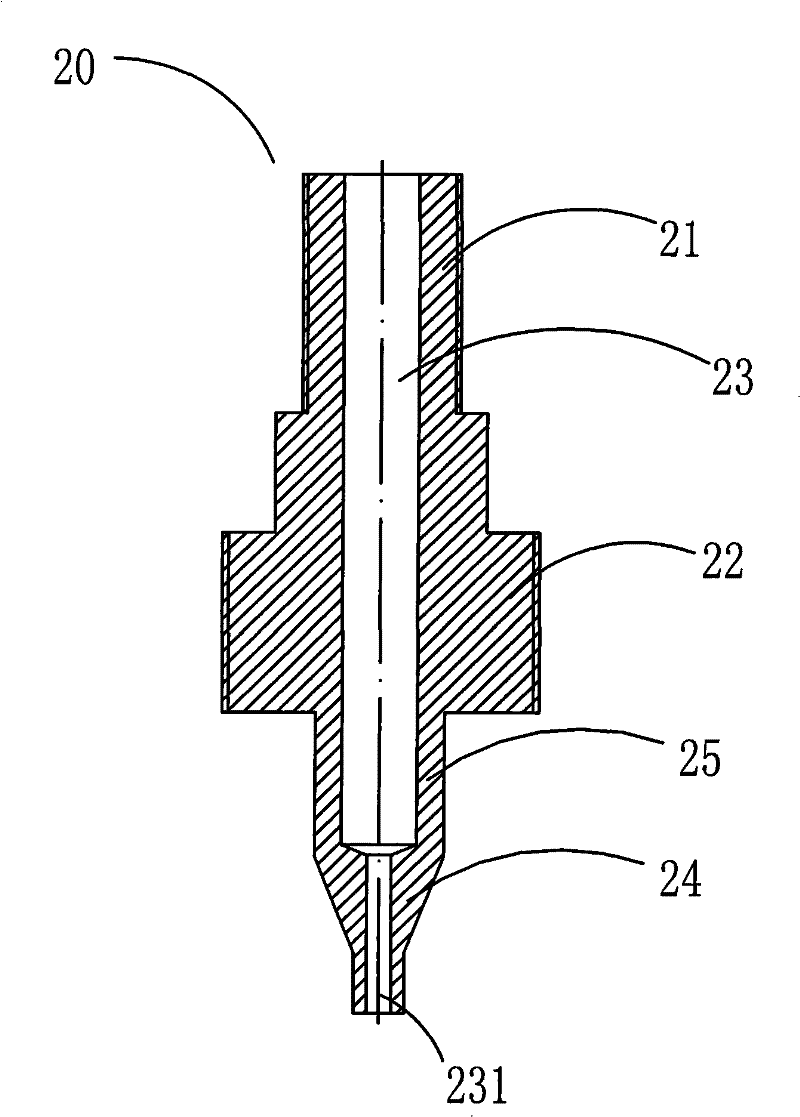

[0018] Such as Figure 5 As shown, a nozzle 100 includes such as figure 1 with 3 As shown in the nozzle body 10 and riser 20, the inside of the riser 20 has a through air chamber 23, the bottom of the air chamber 23 is an air outlet 231, and the diameter of the rest of the air chamber 23 is about three times the diameter of the air outlet . The inside of the nozzle body 10 has a through nozzle cavity, a liquid storage cavity 101 is formed between the nozzle cavity and the riser 20 , and the bottom of the liquid storage cavity 101 is an annular liquid outlet 102 . The caliber of the air outlet 231 is selected between [1.5mm, 2.5mm], and the difference between the inner diameter and the outer diameter of the liquid outlet 231 is between [1.4mm, 2mm], wherein the caliber, inner diameter and outer diameter all refer to diameters, The inner di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com