Lifting type conveyor

A lifting and conveying technology, which is used in transportation and packaging, walking bridge cranes, cranes, etc., can solve the problems of increased manufacturing costs, skewed relative positions, and increased weight of trucks, and can achieve stable handling and prevent relative. Rotation, anti-swing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings, but the present invention is not limited to the illustrated forms, and includes all embodiments that satisfy the requirements described in the claims.

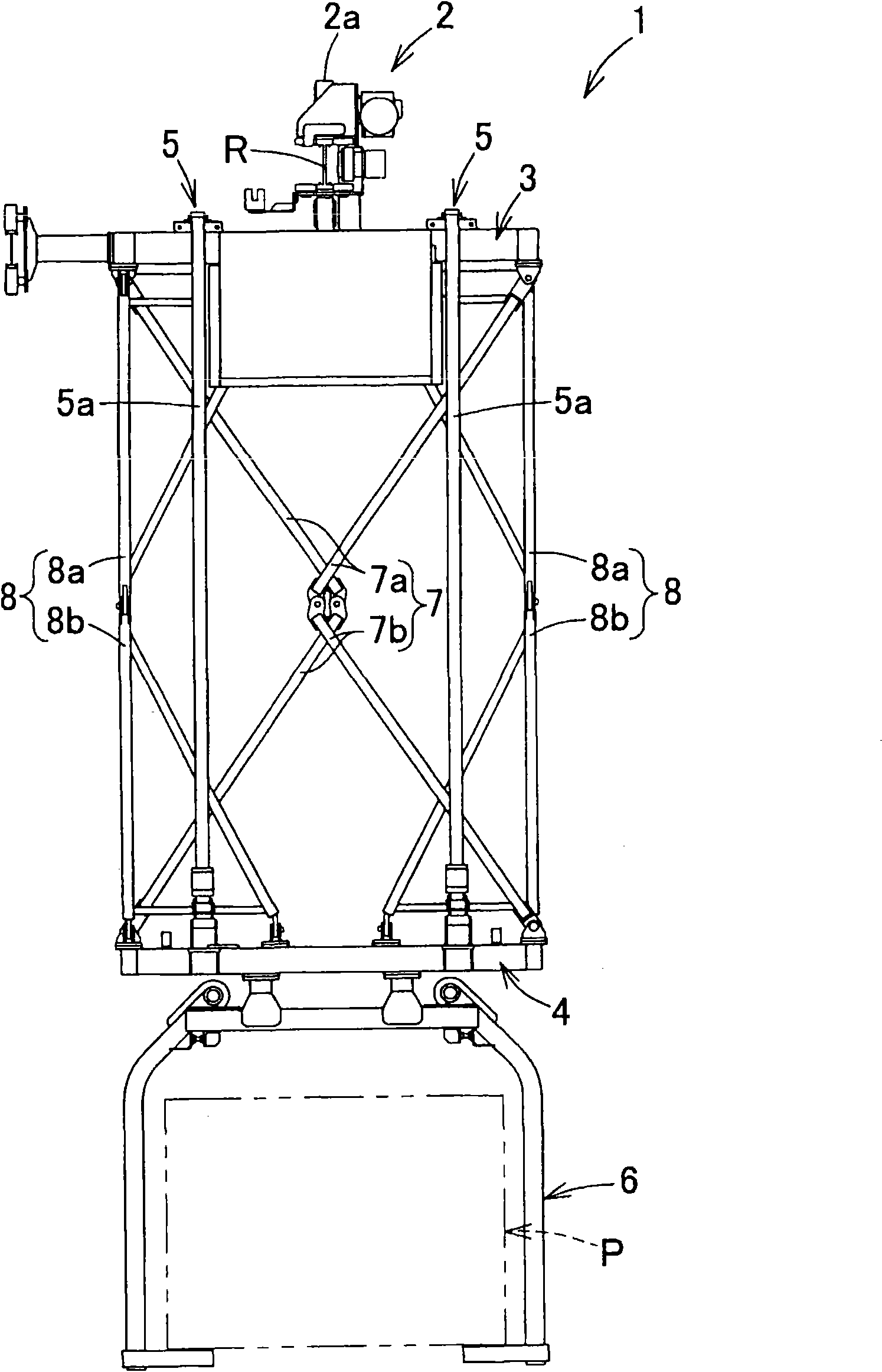

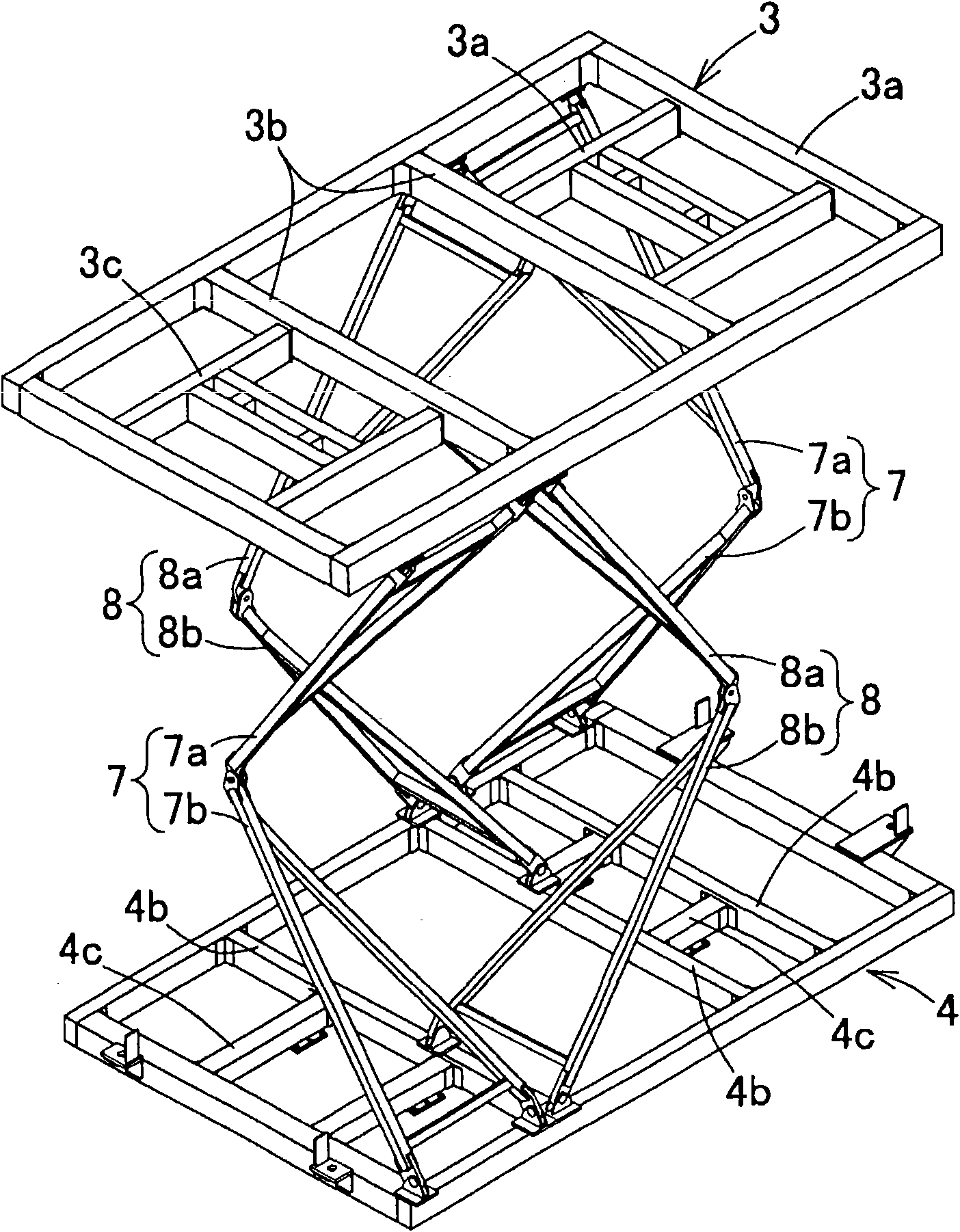

[0026] Figure 1 to Figure 5 It is an explanatory drawing which shows the structure of the elevating lift conveyor 1 of this embodiment. figure 1 It is a front view showing the state where the lower frame 4 of the lift conveyor 1 according to the present embodiment is in the lowermost position, figure 2 for the left view, image 3 It is a perspective view showing the structure of the first and second anti-sway frames 7, 8, Figure 4 It is a front view showing the state where the lower frame 4 of the lift conveyor 1 of this embodiment is at the uppermost position, Figure 5 It is a plan view showing the structure below the upper frame 3 in which the lower frame 4 is in the uppermost position.

[0027] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com