Preformed product and container

A technology of preformed products and container bodies, which is applied in the directions of bottle/container caps, capping containers tightly with caps, bottles, etc., and can solve problems such as cap ring falling off and container neck clamps falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

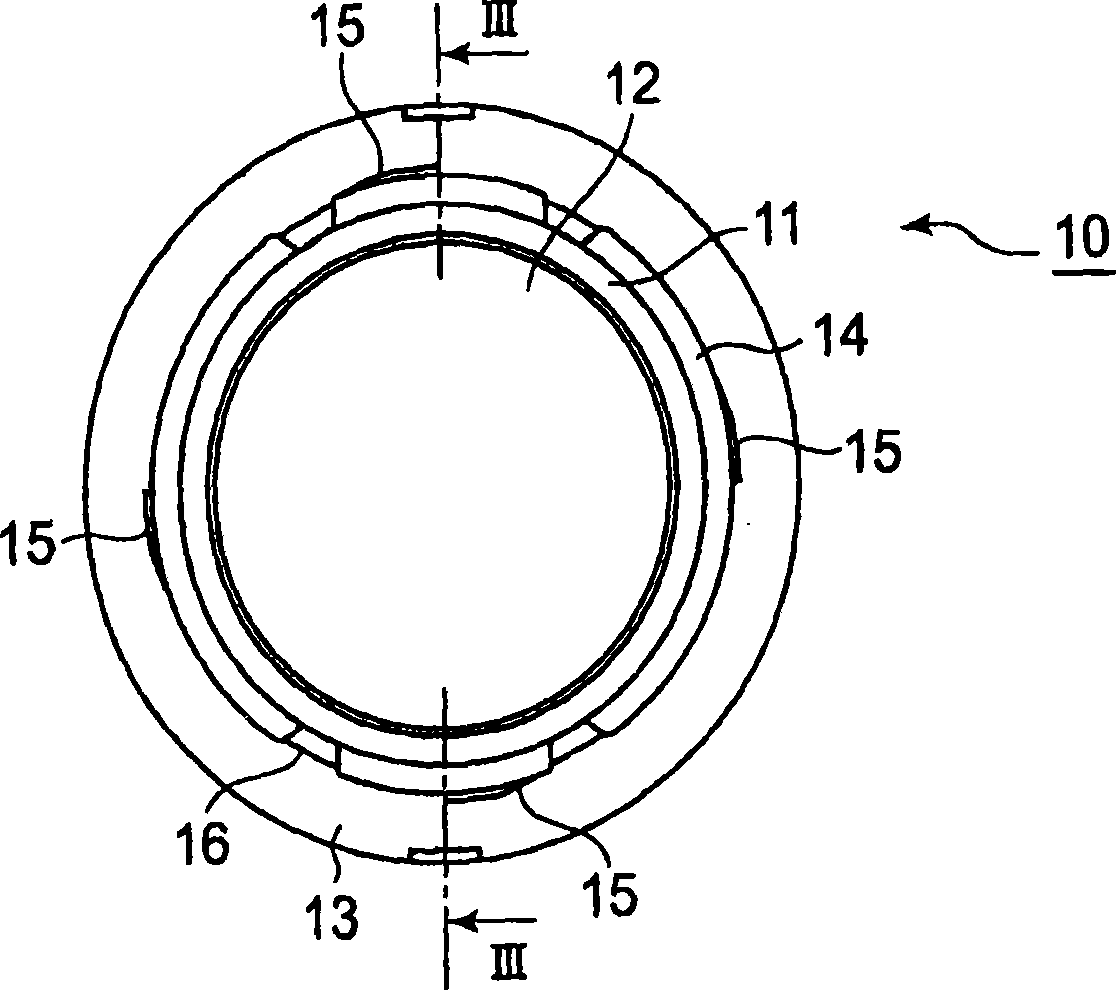

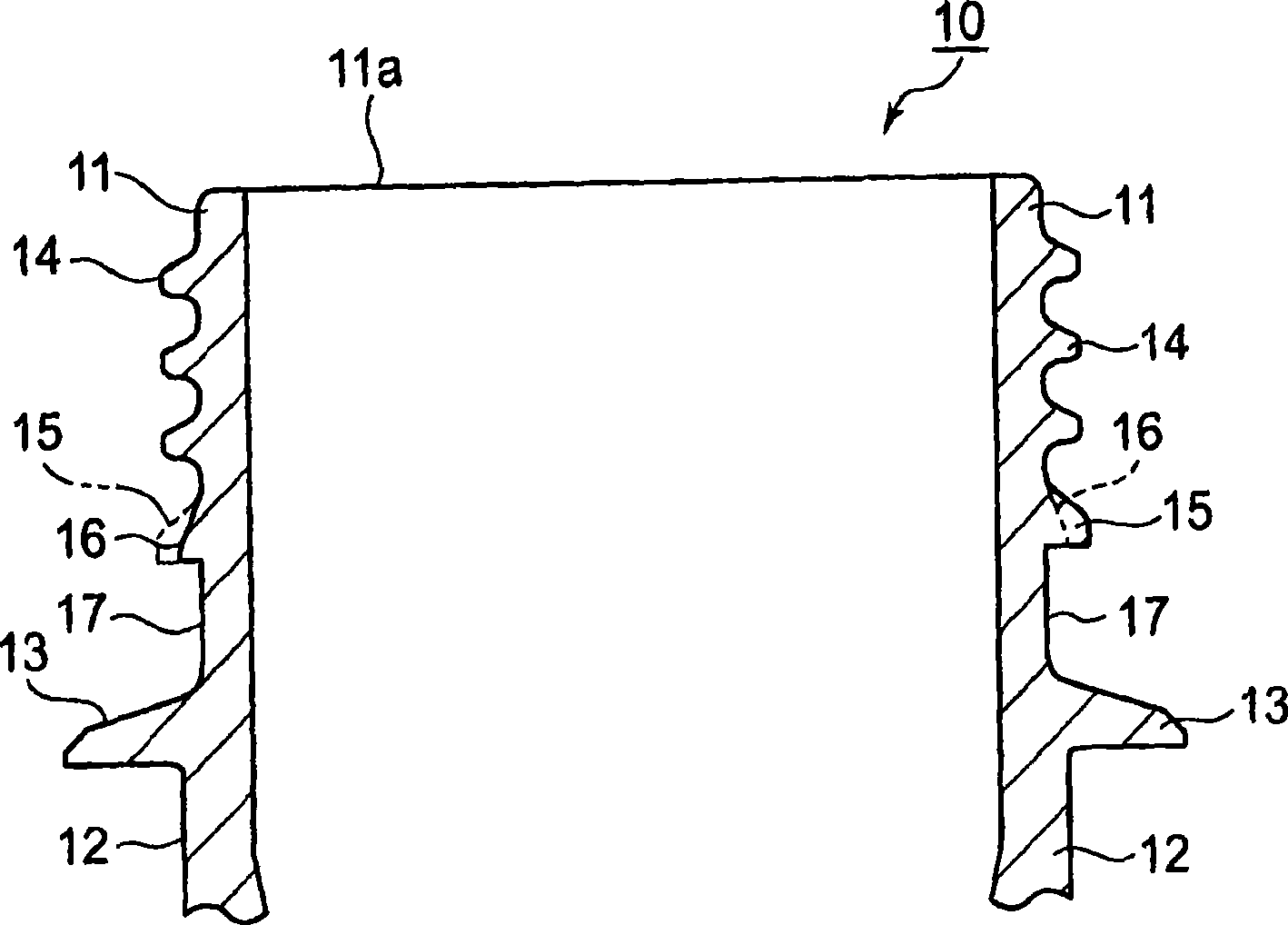

[0059] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings.

[0060] figure 1 It is a front view showing the preform of this embodiment, figure 2 is a plan view showing the preform of this embodiment ( figure 1 II direction view). image 3 is a vertical sectional view showing a preform of this embodiment ( figure 2 III-III line sectional view), Figure 4 is a horizontal sectional view showing a preform of this embodiment ( figure 1 IV-IV line sectional view). Figure 5 yes figure 1 Enlarged view of part V of Figure 6 is a vertical section view of the cap. Figure 7 It is a vertical sectional view showing the container and assembly of this embodiment, Figure 8 It is a figure showing the manufacturing method of a preform, a container, and an assembly. Figure 9 is a diagram showing neck clamps for conveying containers, Figure 10 It is a partially enlarged cross-sectional view showing the container and the ca...

no. 2 Embodiment approach

[0096] Next, refer to Figure 12 to Figure 16 A second embodiment of the present invention will be described.

[0097] here, Figure 12 It is a front view showing the preform of this embodiment, Figure 13 is a vertical sectional view showing a preform of this embodiment ( Figure 12 XIII-XIII line sectional view). Figure 14 yes Figure 12 Enlarged view of Part XIV, Figure 15 It is a vertical sectional view showing the container and assembly of this embodiment. Figure 16 It is a partially enlarged cross-sectional view showing a container and a cap in which the cap main body and the ring are separated. exist Figure 12 to Figure 16 The second embodiment shown differs in that the lower surface of each pawl is spaced apart from the groove upper surface of the circumferential groove portion, and other configurations are substantially the same as those of the above-mentioned first embodiment. exist Figure 12 to Figure 16 in, for with Figure 1 to Figure 11 The same re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com