Assembly limit structure of motorcycle cushion

A limiting structure, motorcycle technology, applied in bicycle saddles, bicycle accessories, transportation and packaging, etc., can solve the problems of shortening the service life of the cover, affecting the firmness of the connection, affecting the comfort of the driver, etc. The effect of comfort and connection firmness, convenient assembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

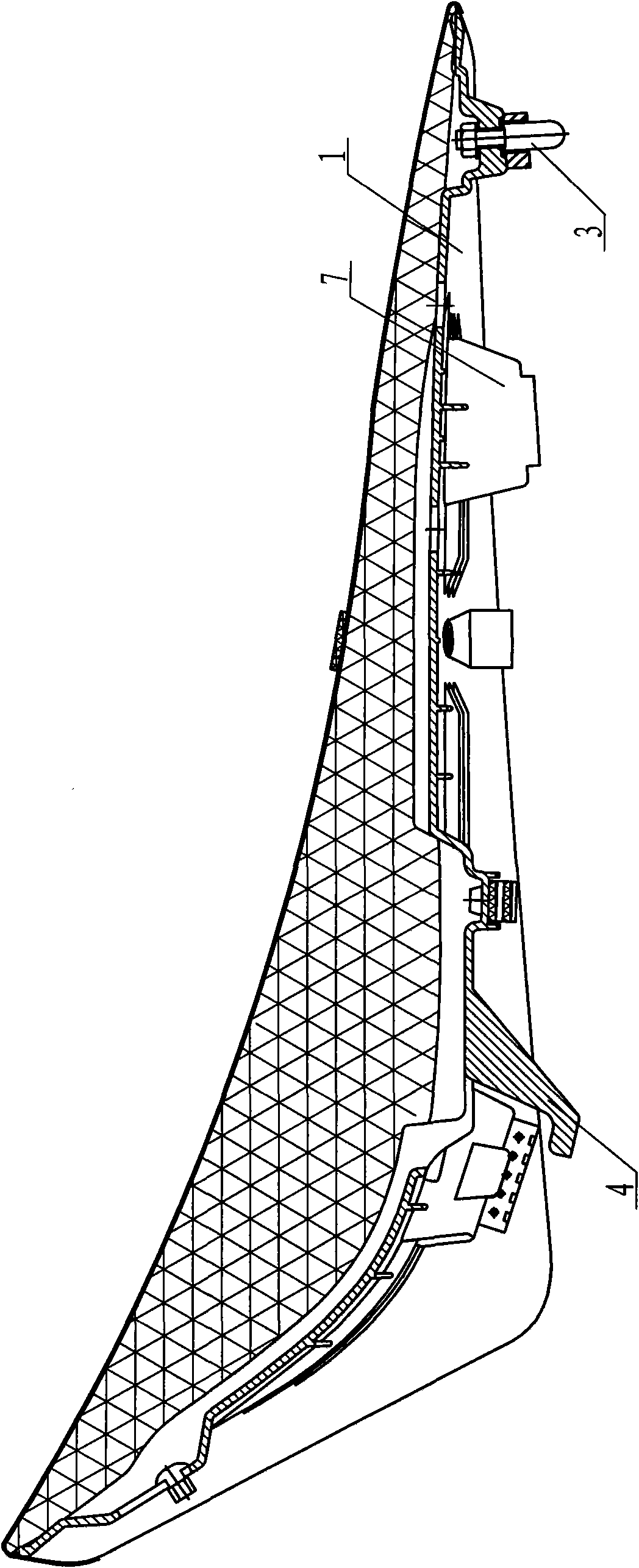

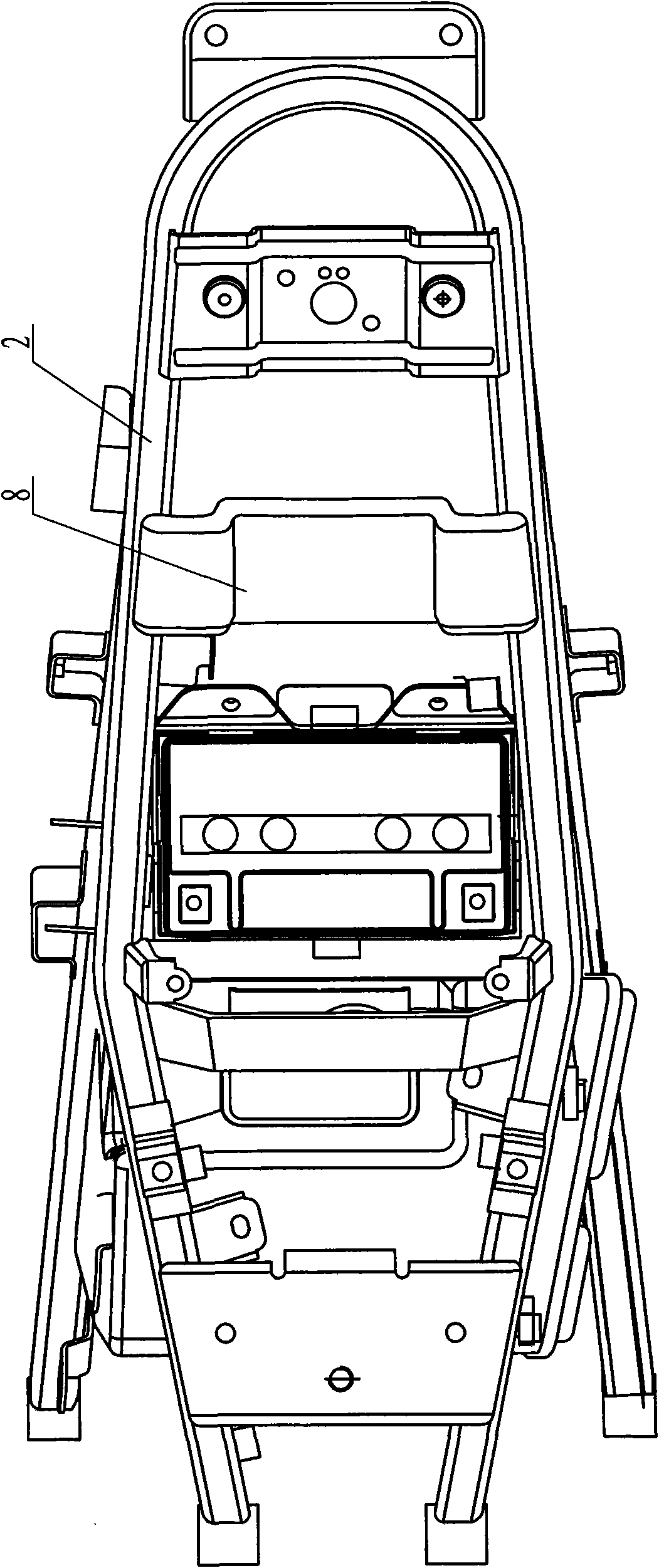

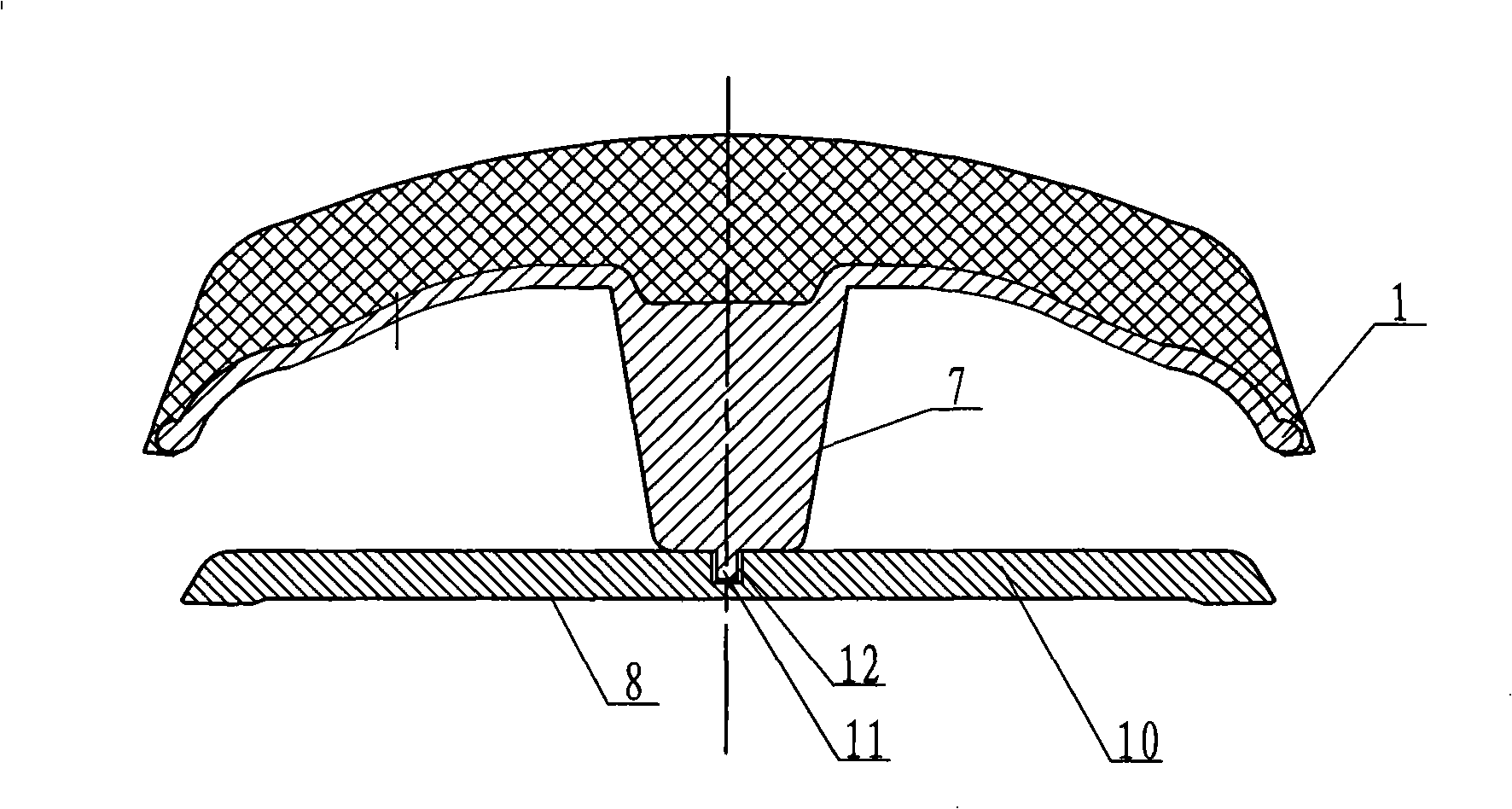

[0016] Such as figure 1 , 2 As shown, the rear part of the seat cushion bottom plate 1 of the present invention is connected with the vehicle frame 2 through the seat cushion lock 3, the front part of the seat cushion bottom plate 1 is connected with the vehicle frame 2 through the hook 4, and the seat cushion bottom plate 1 is provided with a boss 7, A support plate 8 opposite to the boss 7 is provided on the vehicle frame 2 , and a limiting member for limiting the lateral movement of the seat cushion bottom plate 1 relative to the vehicle frame 2 is provided between the boss 7 and the support plate 8 .

[0017] The present invention is assembled like this: After foam and leather are installed on the seat cushion base plate 1, then the seat cushion base plate 1 is installed on the vehicle frame 2 through the seat cushion lock 3 and the hook 4, and the boss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com