Parallel shaft-type automatic gearbox series

An automatic transmission, series of technology, applied in the direction of transmission, gear transmission, belt/chain/gear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The structure and shifting principle of the present invention can be used Figure 1 to Figure 46 Five-, six-, seven-, eight- and nine-speed automatic transmissions and automatic manual transmission mechanisms are illustrated.

[0057] Such as figure 1 Vehicle powertrain 501 is shown, five speed automatic transmission gearbox 501G driven by engine 501E.

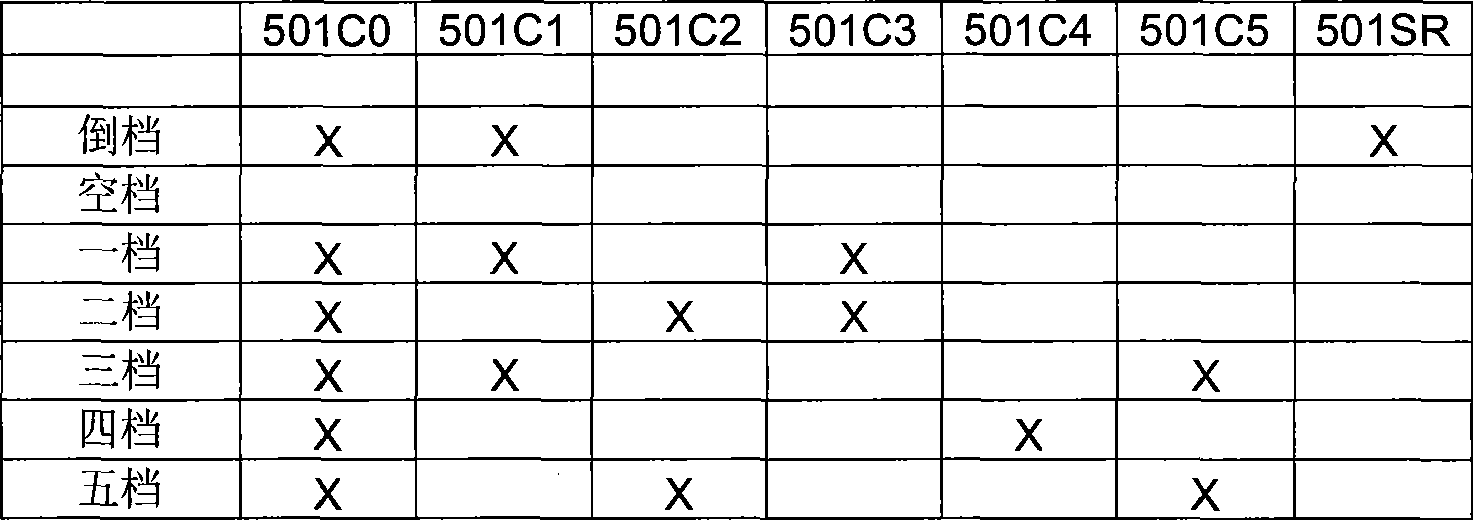

[0058] The five-speed automatic transmission gearbox 501G includes a mechanical shock absorber 501D, a main clutch 501C0, an input shaft 501A1, an output shaft 501A2 and an intermediate shaft 501A3. 501E can be connected with the input shaft 501A1 through the main clutch 501C0. The gearbox 501G also includes a series of gears, including a gear 501G1 fixed on the input shaft 501A1, which can rotate freely on the input shaft 501A1 and is respectively connected with the gears 501G4 and 501G7 through clutches 501C1 and 501C2, which can be rotated on the output shaft 501A2. The upper gear 501G2 is freely rotating and conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com