Method for full automatically subpackaging sealing structure glue

A sealed structure, fully automatic technology, used in packaging, bottling machines, liquid bottling, etc., can solve the problems of inaccurate measurement, environmental pollution, affecting the overall quality of products, etc., and achieve the effect of high sub-packaging efficiency and accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Before subpackaging the packaging bottles and bottle caps, if there are dirty substances attached, these packaging bottles and bottle caps need to be washed and dried in advance.

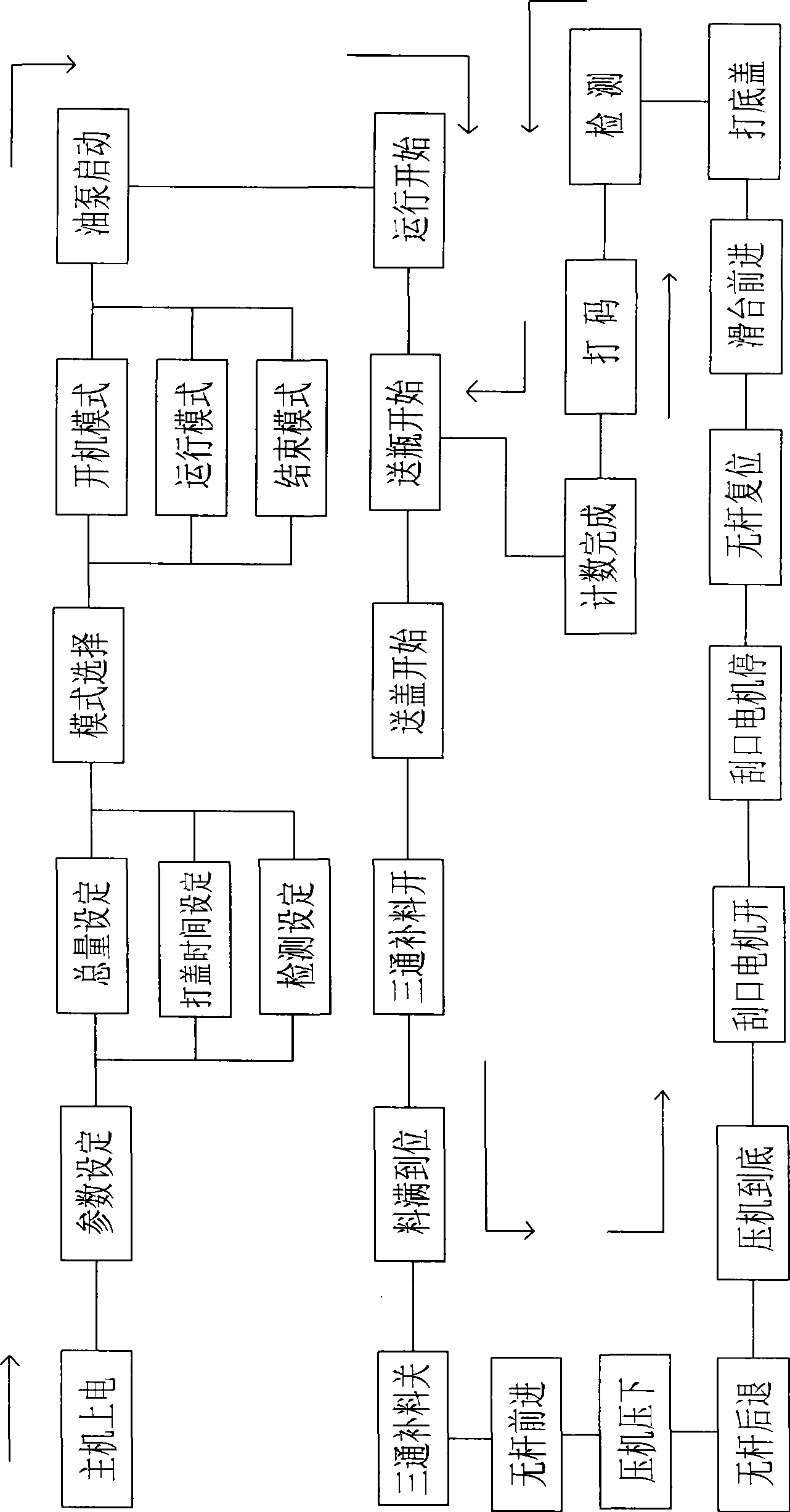

[0016] Such as figure 1 As shown, the figure 1 It is a schematic process flow diagram of the present invention. Before subpackaging, it is necessary to obtain qualified structural adhesives through transportation from the pre-installed structural adhesive production device.

[0017] First set the parameters during subpackage operation. The setting can be one or more of the total amount setting, capping time setting, and detection setting;

[0018] Then select the mode to determine the startup mode, operation mode and end mode to be used.

[0019] Then send the bottle, gradually send the structural glue into the packaging bottle, and then start to send the bottle cap. When the structural glue in the bottle is about to reach the set material position, open the three-way to replenish the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com