Safety syringe

A safety syringe and inner needle holder technology, applied in the field of medical devices, can solve the problems of not easy one-handed operation, complex product structure, difficulty in mold opening and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

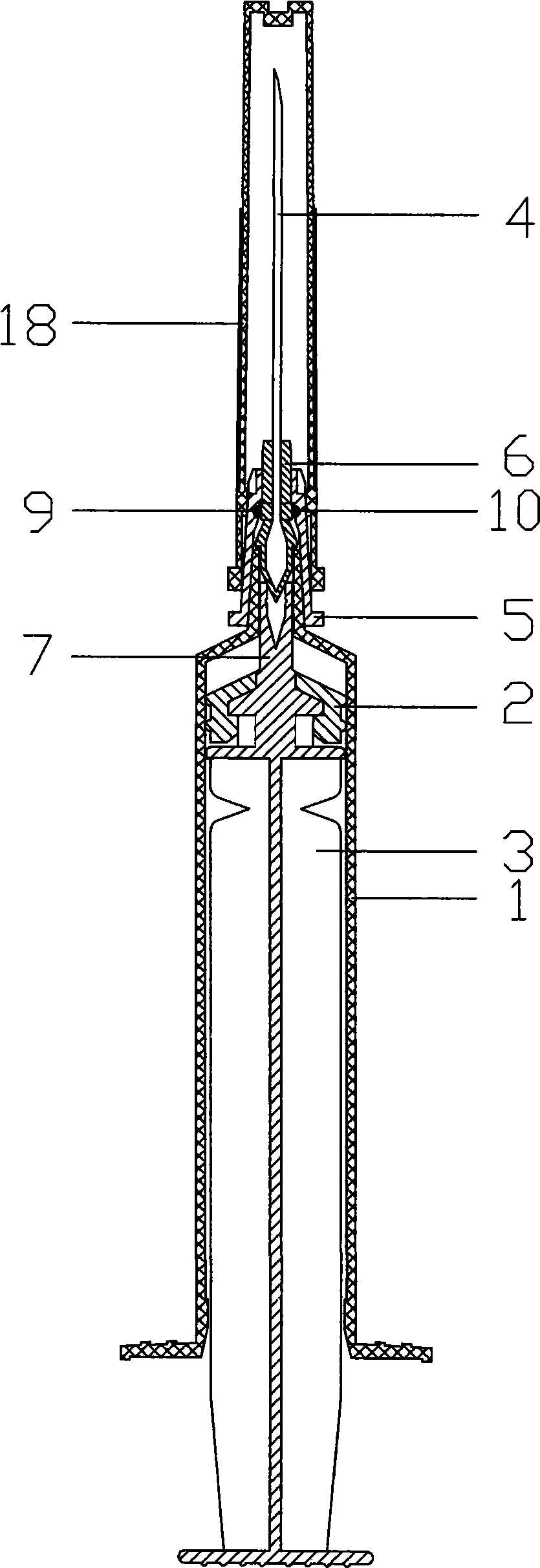

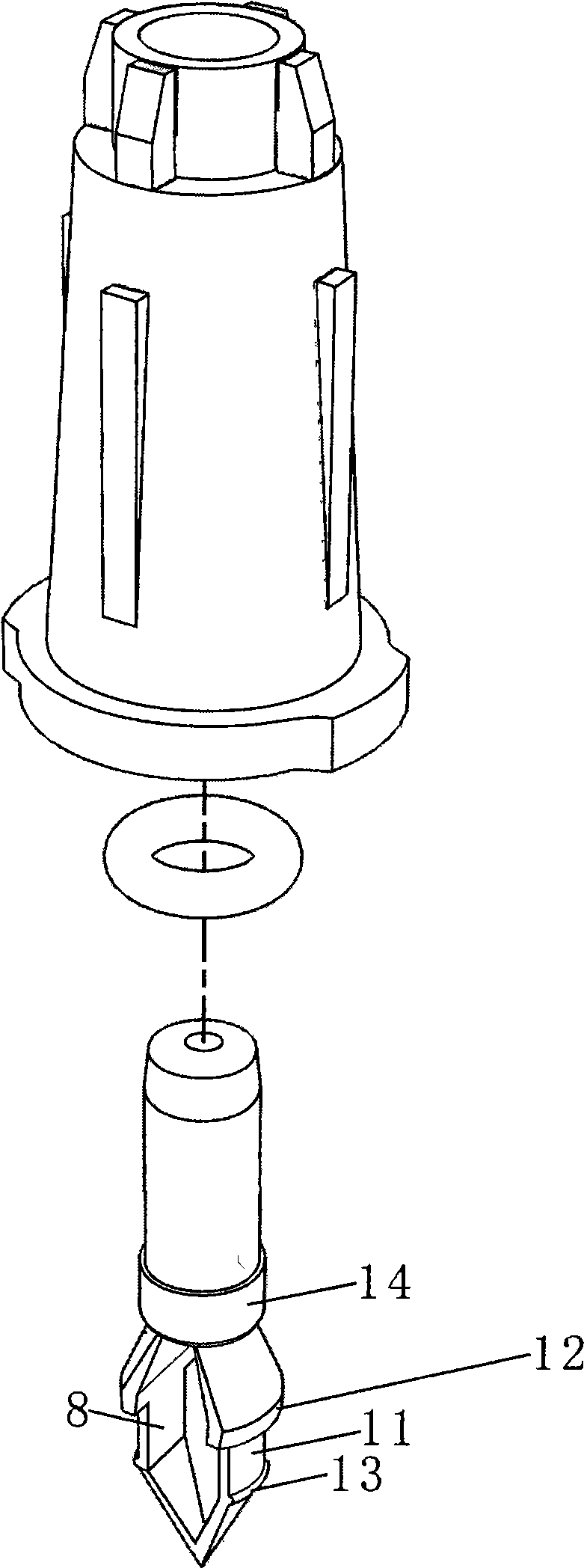

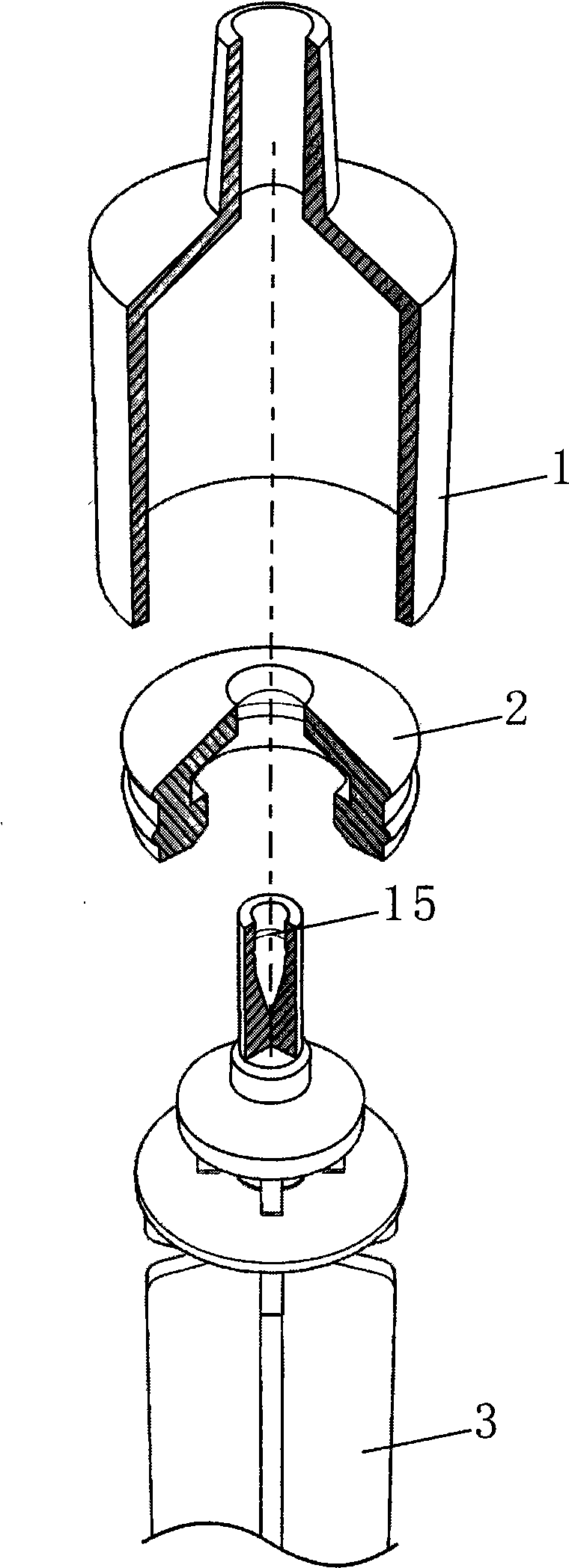

[0047] Below with reference to accompanying drawing, the present invention is further described

[0048]The present invention is a safety syringe, which mainly includes a barrel body 1, a needle head is arranged at the end of the barrel body 1, a needle tube 4 is arranged at the end of the needle head, a core rod 3 is arranged inside the body body 1, and a needle rod is arranged near the end of the core rod. The rubber stopper 2 is different from the prior art in that the needle head is formed by socketing the outer needle base 5 and the inner needle base 6, and the end of the core rod 3 is provided with a pull-back post 7 protruding from the On the surface of the rubber plug 2, the upper part of the inner needle seat 6 is cylindrical, and the lower part of the inner needle seat 6 is formed by a fin 8, one end of the fin 8 is fixed on the above-mentioned cylindrical end, and the other ends of the two fins 8 are combined into one Conical structure, the combined structure of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com