Flattened bamboo panel

A technology of bamboo boards and boards, which is applied in the direction of mechanical processing of plant materials, mechanical equipment, etc., can solve the problems of high manufacturing cost, low material utilization rate, and low raw material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

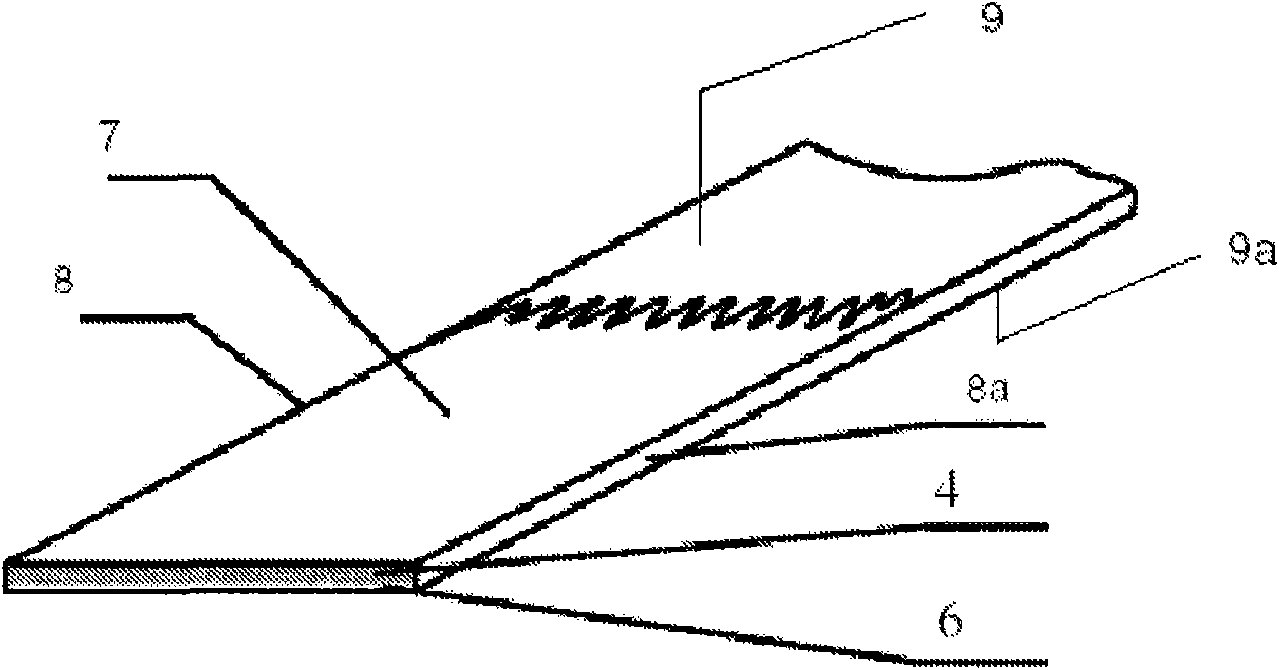

[0023] The present invention provides a flattened bamboo board comprising a single layer of bamboo stalk walls, wherein the bamboo stalk walls comprise an outer zone, a middle zone and an inner zone, wherein the outer zone and the inner zone Each of includes the outermost part. In one embodiment of the present invention, said flattened bamboo board consists of a single bamboo tube.

[0024] The term "plank" refers to relatively thin, flat pieces of wood or the like. In this invention, the term "board" refers to a relatively thin, flat piece of bamboo.

[0025] The methods disclosed in this invention may not involve the use of adhesives. In one embodiment, no adhesive is used for the flattened bamboo board. In another embodiment of the present invention, the flattened bamboo board is a high density board.

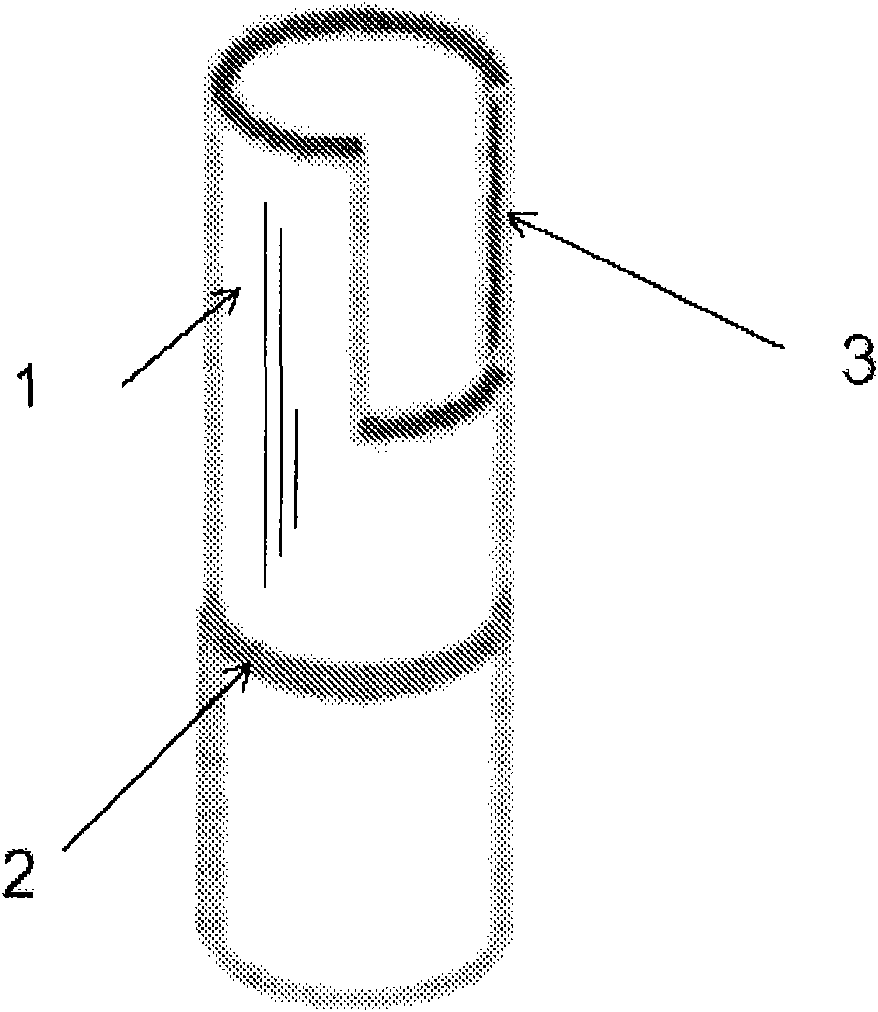

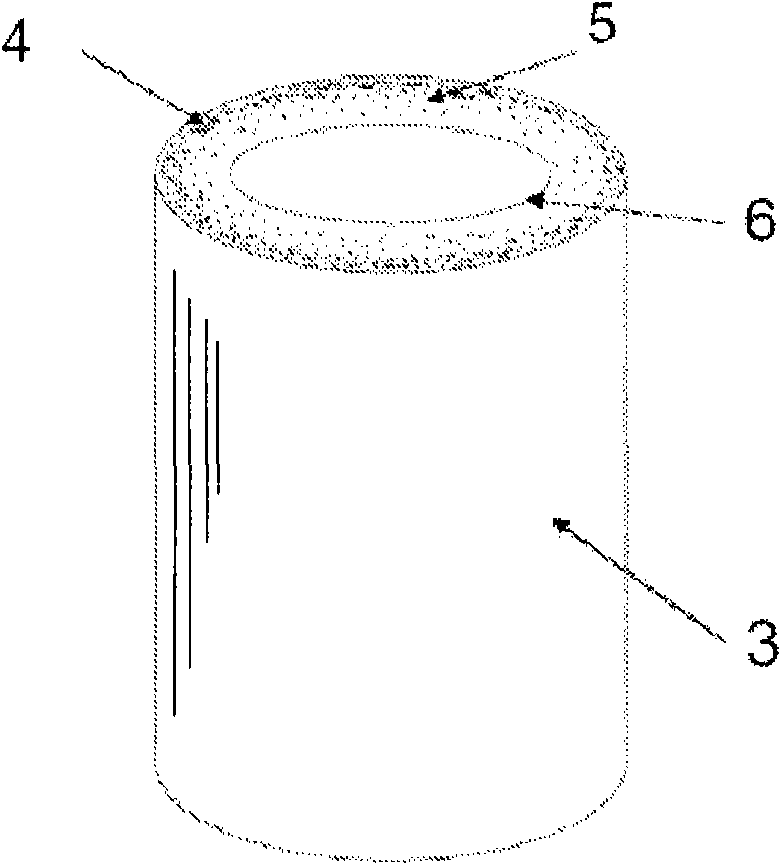

[0026] See attached picture, figure 1 A part of the bamboo tube is shown in , which shows that the bamboo tube 1 includes bamboo nodes 2 and bamboo walls 3 . An enlarg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com