Optical lens group

An optical lens and lens technology, which is applied in the field of optical lens sets, can solve the problems of the second lens 26 being skewed, the supporting position is not fixed, and the mirror spacing is out of specification, so as to achieve the effects of reducing the impact, not easy to skew, and easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

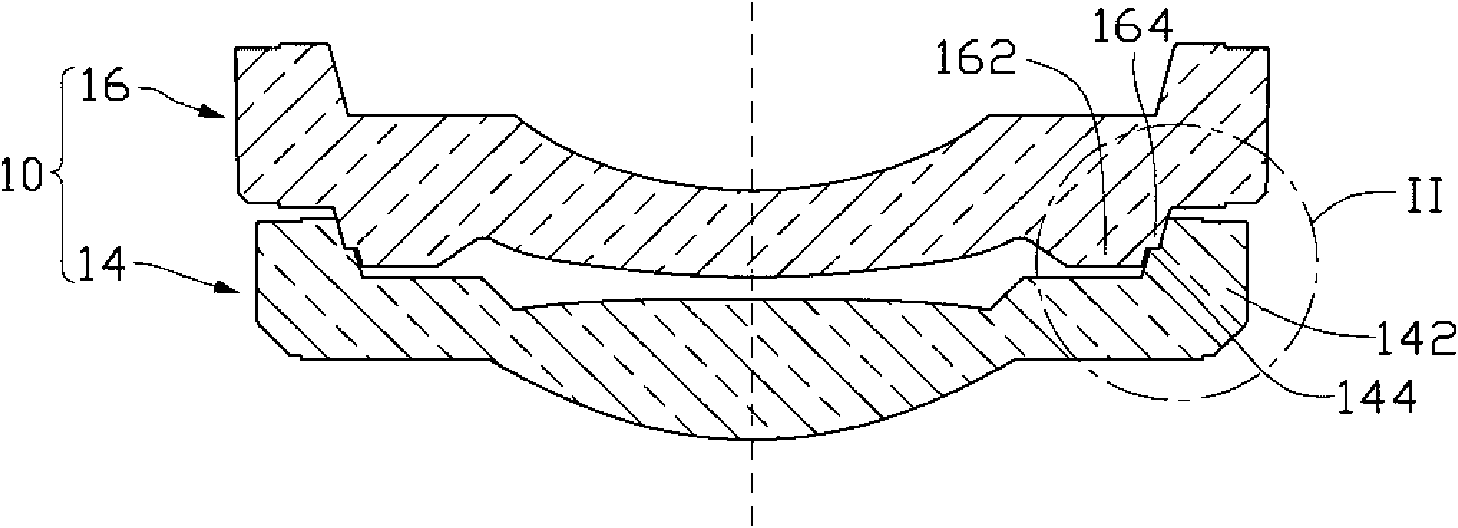

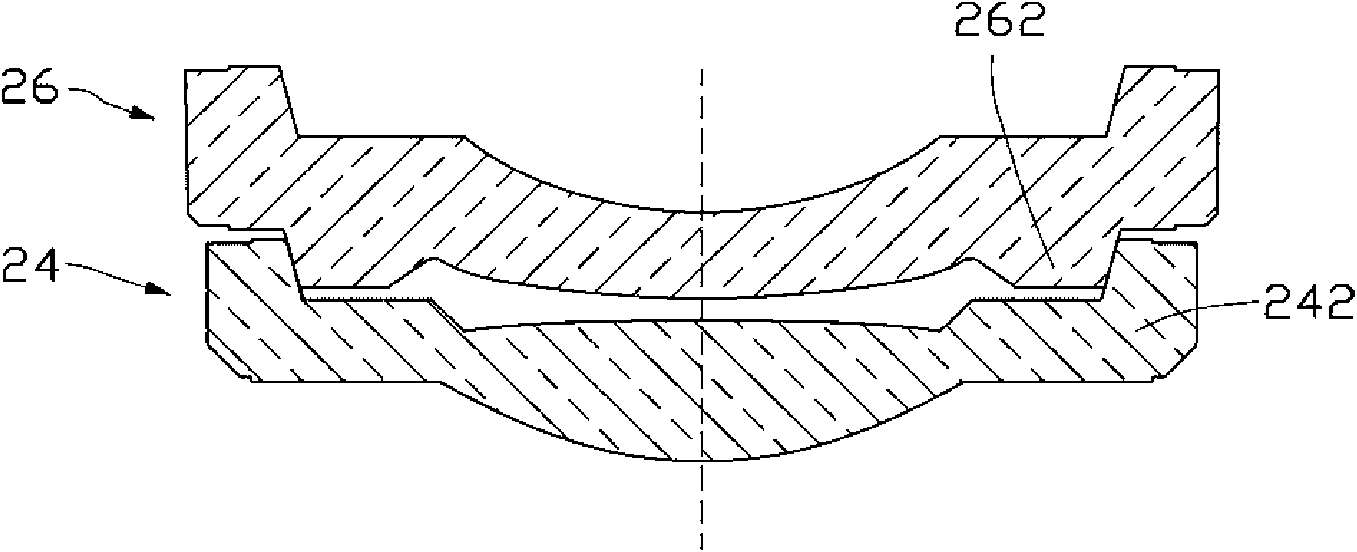

[0012] see figure 1 , which is an optical lens set 10 provided by the embodiment of the present invention, which includes a first lens 14 and a second lens 16 .

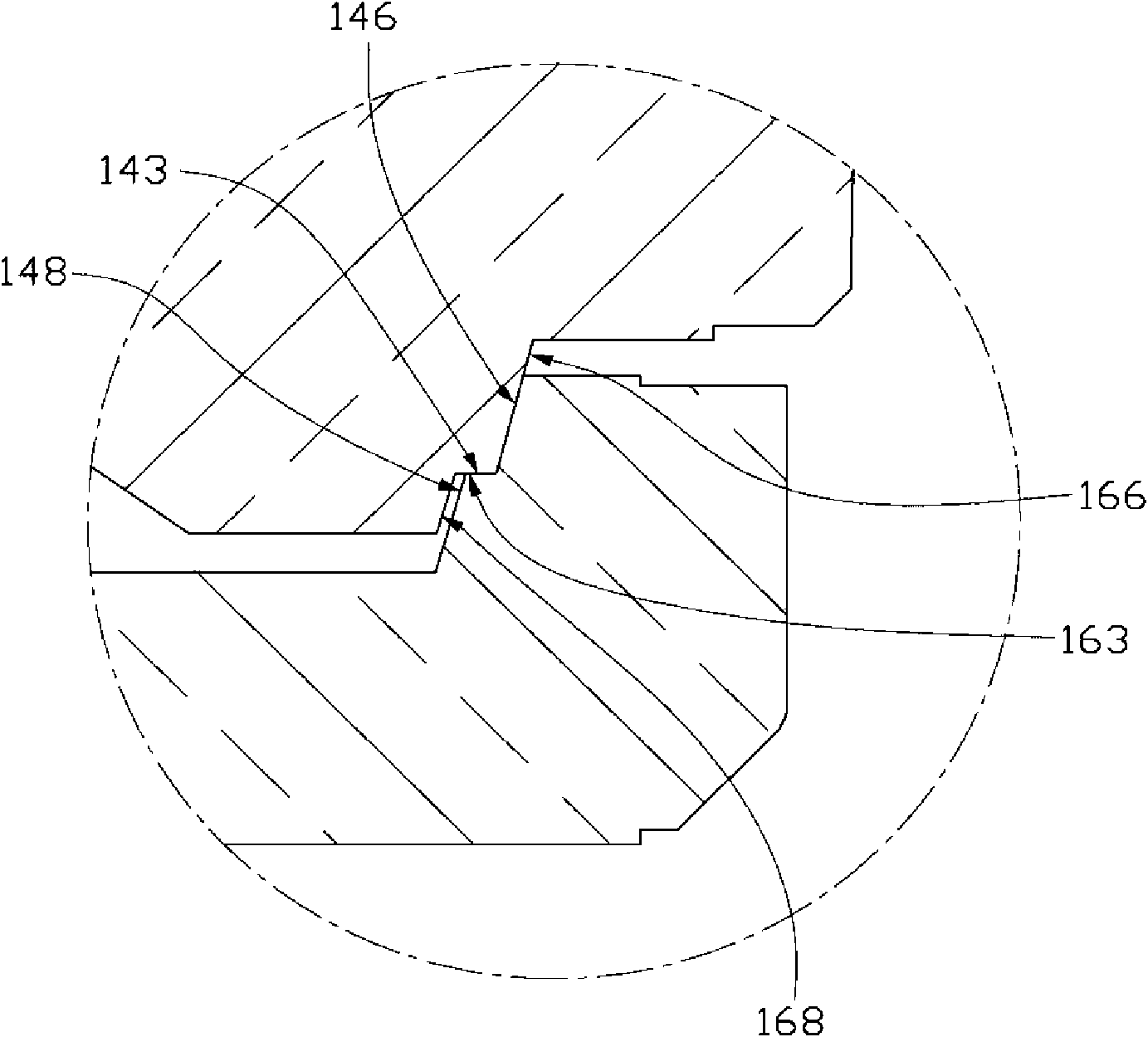

[0013] The first lens 14 includes an optical part at the center of the lens and a fixing part at the periphery of the lens for fixing the lens. The optical part is used to achieve a certain optical effect during the imaging process, while the fixing part is only used to fix the lens and does not participate in the imaging. A protruding step 142 is disposed on the periphery of the first lens 14 . The steps are distributed in a ring shape with the lens center of the first lens 14 as the center.

[0014] Similarly, the second lens 16 also includes an optical portion located at the center of the lens and a fixing portion located at the periphery of the lens for fixing the lens. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com