Harvester for peanut

A technique for peanut harvesters and racks, which is applied to excavating harvesters, harvesters, and topping machines, etc., can solve the problems of seedling winding downtime, waste of farmers' time, broken bricks and crushed stones, etc. Seedling emergence is regular and orderly, and the effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

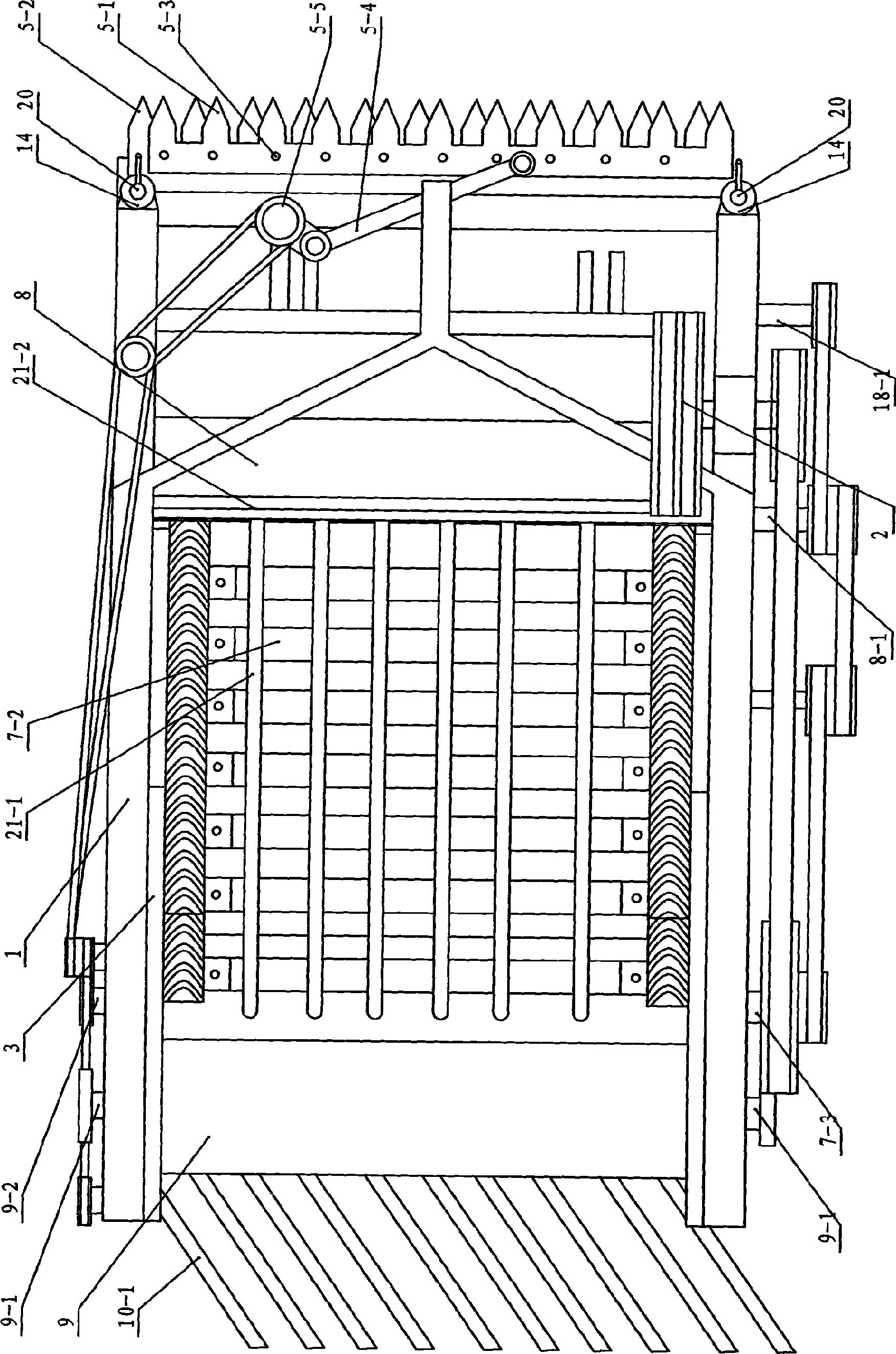

[0031] Embodiment one: refer to the accompanying drawings of the description, refer to figure 1 , figure 2 , image 3 , Figure 4 ,

[0032] A peanut harvester, comprising a frame 1 and a transmission mechanism 2, frame plates 3 are arranged on both sides of the frame 1, and a depth-setting roller 4, a seedling cutter 5, and a plow shovel 6 are installed on the front of the frame 1 , spiral seedling splitter 31, in the middle of the frame, there is a chain conveyor 7 with low front axle 7-1 and high rear axle 7-3, and the front end rotating shaft 7-1 of the chain conveyor 7 is positioned at the rear of plow shovel 6 , be provided with pressure roller 8 on the top of chain row conveying device 7 front ends, the rear portion of frame 1 is provided with upper and lower pressure-breaking soil rollers 9 and 29, is provided with seedling harvester 10 at the rear portion of breaking soil rollers, frame 1 two The bottom of the side is provided with road wheels 11, the front axle ...

Embodiment 2

[0041] Embodiment two: see Figure 5 , Image 6 , Figure 7 , Figure 8

[0042] A peanut harvester, comprising a frame 1 and a transmission mechanism 2, frame plates 3 are arranged on both sides of the frame 1, and a depth-setting roller 4, a seedling cutter 5, and a plow shovel 6 are installed on the front of the frame 1 , spiral seedling splitter 31, in the middle of the frame, there is a chain conveyor 7 with low front axle 7-1 and high rear axle 7-3, and the front end rotating shaft 7-1 of the chain conveyor 7 is positioned at the rear of plow shovel 6 , be provided with pressure roller 8 on the top of chain row conveying device 7 front ends, the rear portion of frame 1 is provided with upper and lower pressure-breaking soil rollers 9 and 29, is provided with seedling harvester 10 at the rear portion of breaking soil rollers, frame 1 two The bottom of the side is provided with road wheels 11, the front axle 7-1 and the rear axle 7-3 of the chain conveyor 7, the axle 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com