Automatic identification method and device of carton for automatic packing production chain

An automatic identification and automatic packing technology, which is applied in the field of automatic identification, can solve the problems of large and complex devices and control systems, inconvenient operation, and large workshop area, and achieves increased image printing workload, simple results, and small detection and identification area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A carton automatic identification method for an automatic packing production line, comprising the following steps:

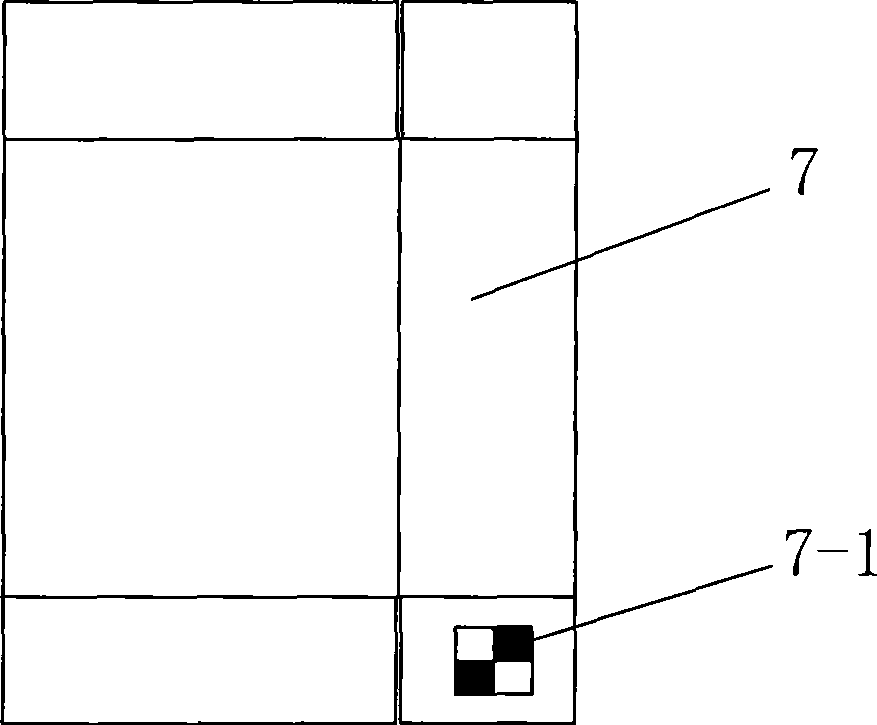

[0028] (1) if figure 2 As shown, on the carton 7 to be detected for packaging, print an area of no more than 50cm according to the corresponding product model 2 The rectangular pattern 7-1 is used as the corresponding detection mark;

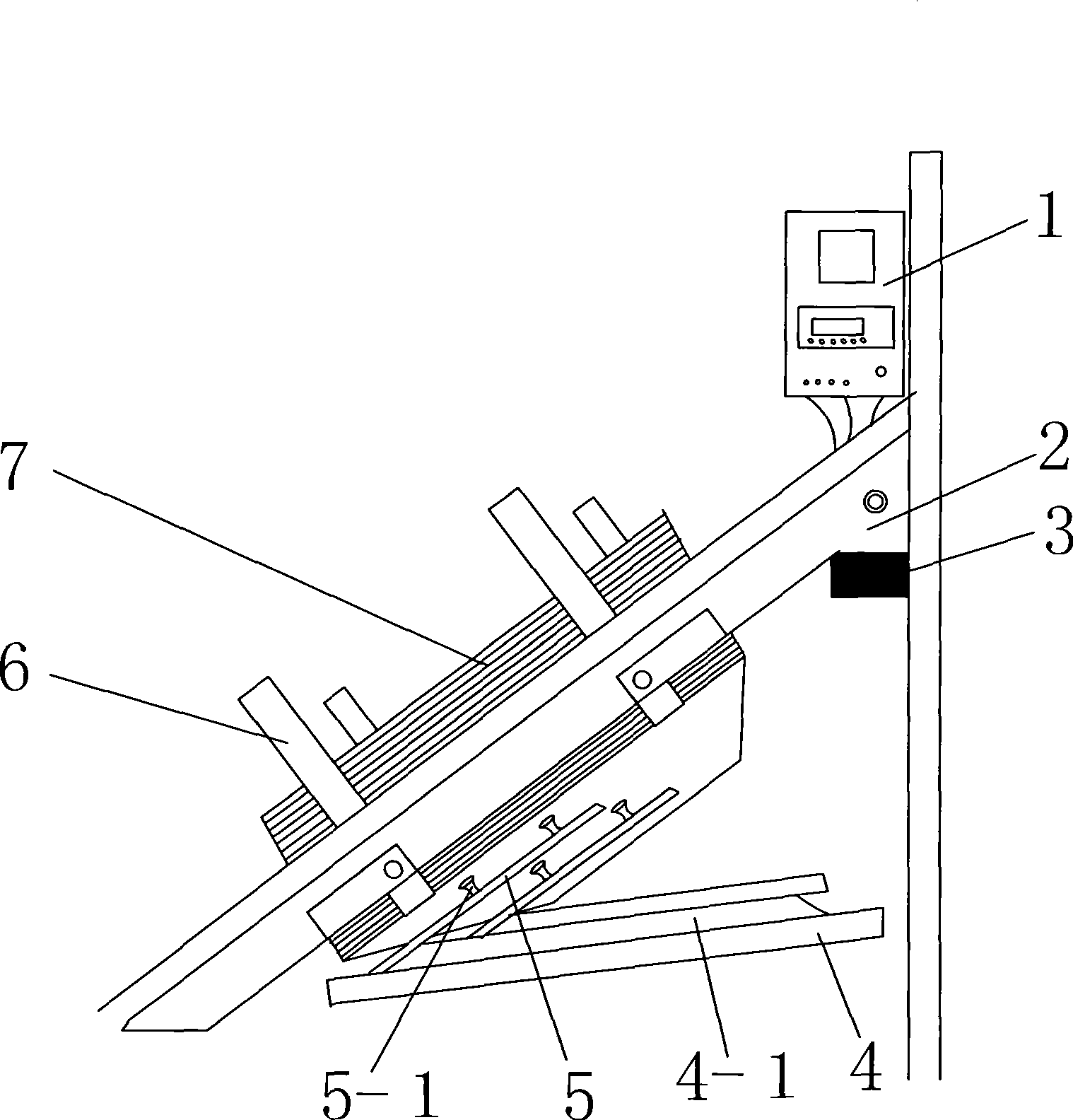

[0029] (2) if figure 1 The device shown in the image processing system 1 is used to set the detection and identification standard data;

[0030] (3) The taking-out mechanism 5 takes out the carton 7 to be detected from the storage mechanism 6 and places it on the detection station 4-1, and the camera 3 with a detection sensor collects the rectangular pattern 7-1 on the carton 7 to be detected as a detection mark pattern data, and send it to the image processing system 1;

[0031] (4) The image processing system 1 processes the pattern data, and then compares it with the standard data set in step (2); if the two are c...

Embodiment 2

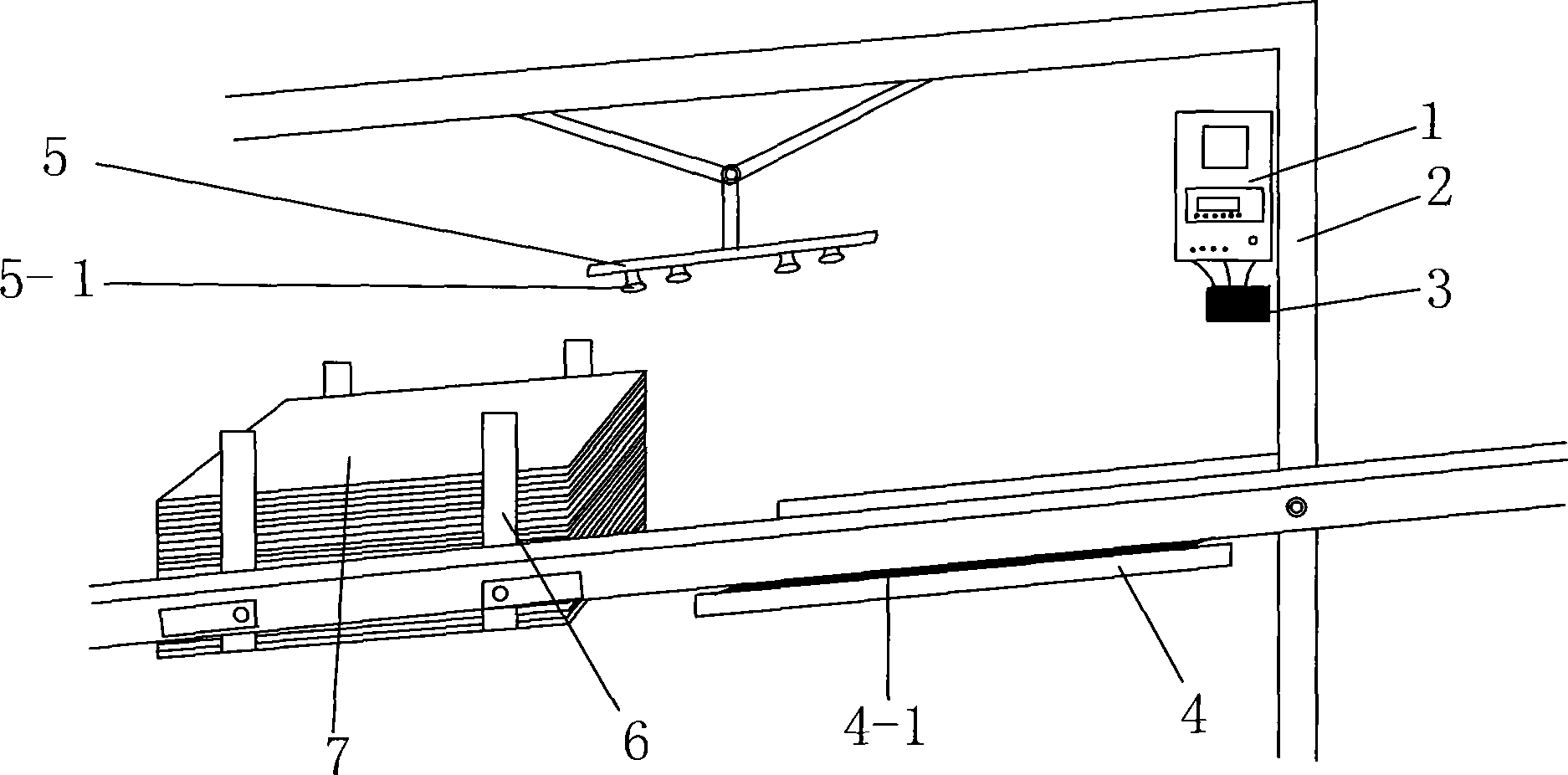

[0035] The carton automatic identification method used in the automatic packing production line in this embodiment is the same as that in Embodiment 1.

[0036] For the carton automatic identification device of above method, its structure is as follows image 3 As shown, it includes the support 2 of the automatic packing production line and the conveyor belt 4 provided with the detection station; the front end of the conveyor belt is provided with a storage mechanism 6 and the cartons 7 to be detected are taken out one by one from the storage mechanism 6 to the The box taking mechanism 5 of the detection station; the camera 3 and the image processing system 1 connected thereto are also fixed on the bracket 1, and the detection station 4-1 of the carton 7 to be detected is located within the data acquisition range of the detection sensor. Wherein, the box storage mechanism 6 is fixed on the bracket 2 by four connectors with flanges at the bottom, the box storage mechanism 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com