Rotating seal

A technology of rotary seal and ring seal, which is applied in the direction of engine seal, engine components, mechanical equipment, etc., can solve the problems of complex mechanical seal structure, inconvenient maintenance and inability to solve gas leakage, etc., and achieve important economic and social benefits, Installation, maintenance and replacement are convenient, and it is beneficial to the effect of repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described as follows in conjunction with accompanying drawing and embodiment:

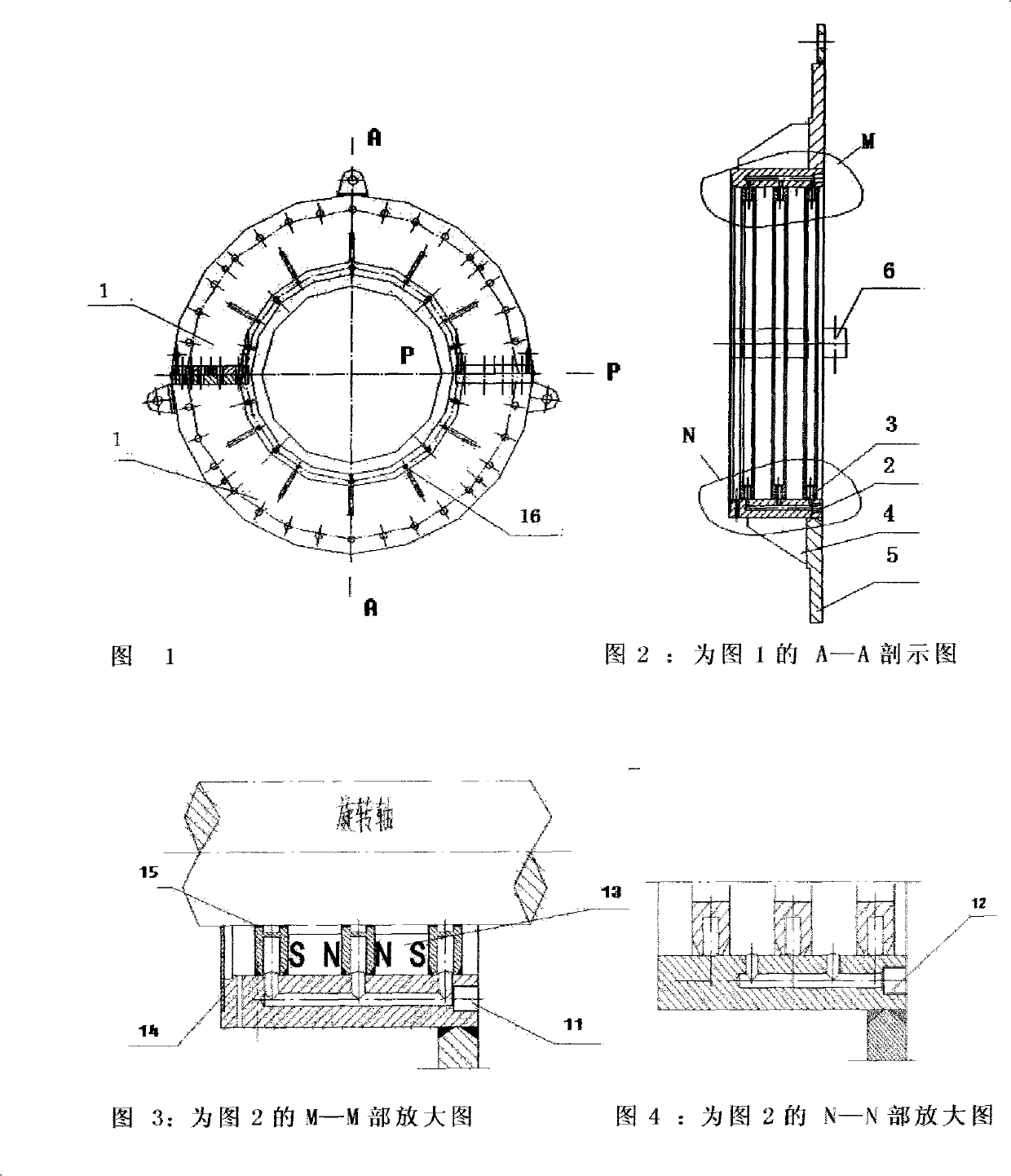

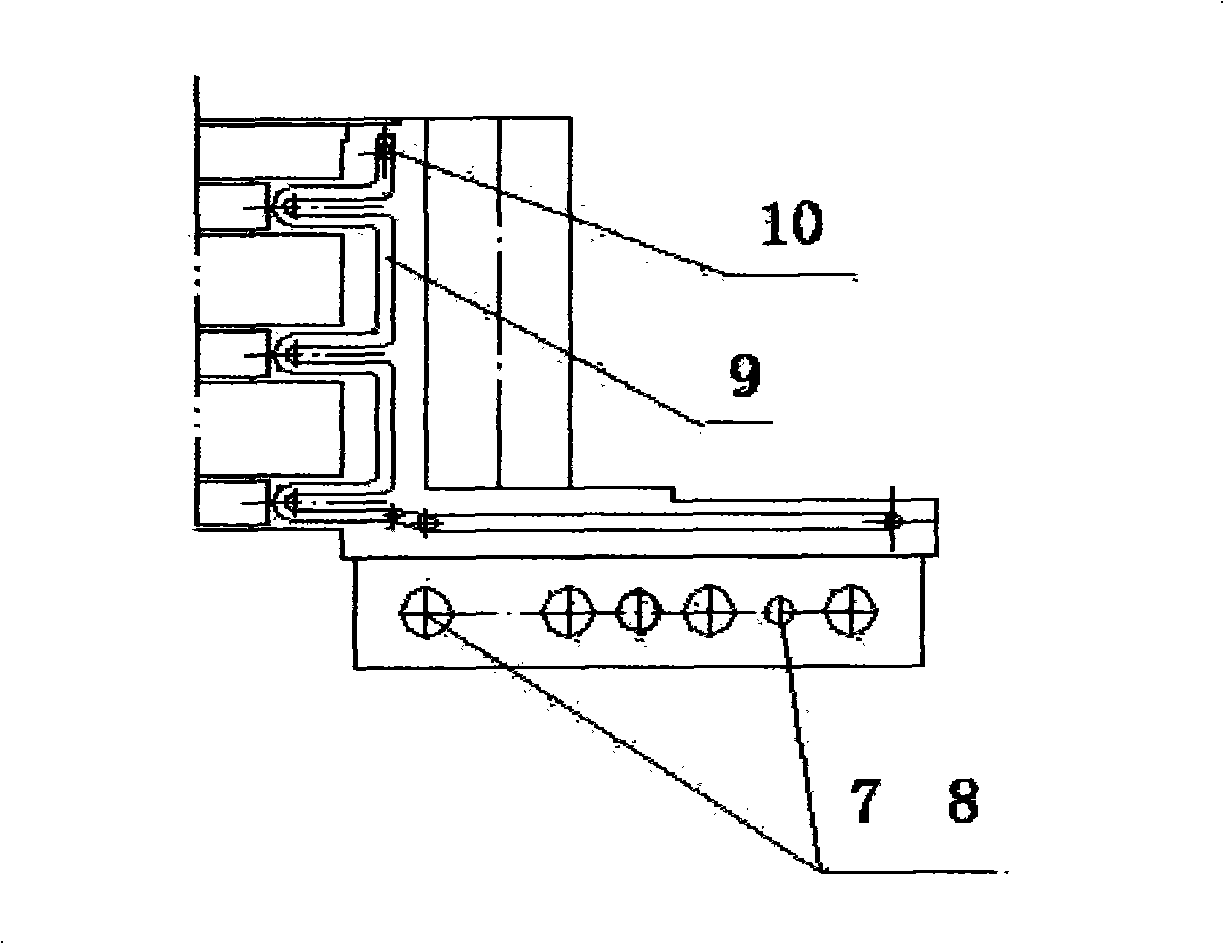

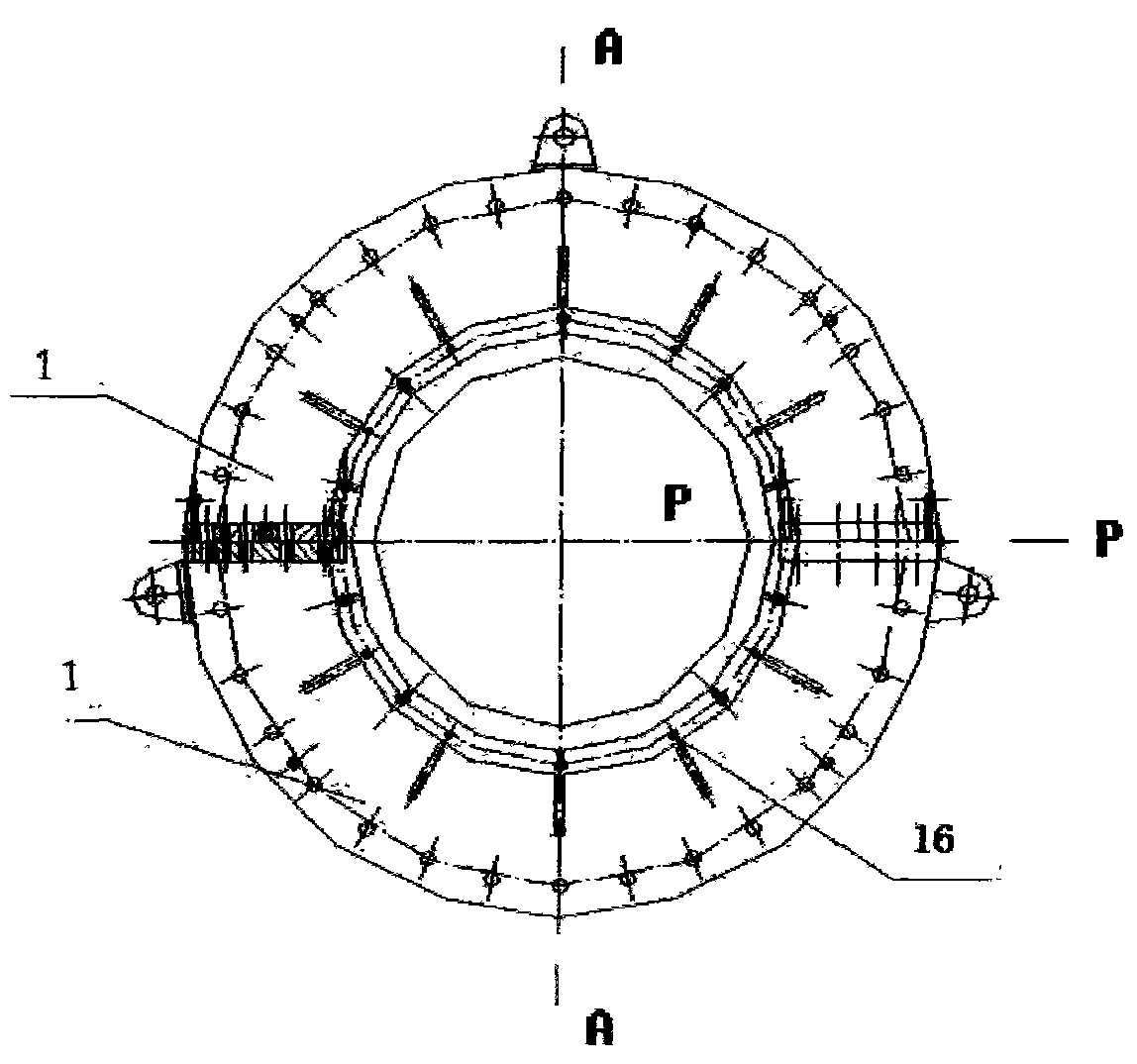

[0034] As shown in Figures 1 to 5, it is a kind of rotary seal, which is composed of two upper and lower half-ring seals 1 connected to form a full-circle ring seal; the half-ring seal 1 has a half-ring base 2, and the half-ring base 2 is set The components include a cooling water jacket 3 , an end cover connecting plate 5 , and a half-ring seal connecting plate 6 for connecting two half-ring seals 1 ; there are cooling circuits and grease filling holes 12 on the half-ring base 2 . The opening angle of the upper and lower half-ring seals 1 is 180°, and each half-ring seal 1 is a welded integral structure; the half-ring base 2 also has ribs 4 for strengthening the connecting plate 5 of the end cover; cooling water jacket 3 , the end cover connecting plate 5, the semi-ring sealing connecting plate 6, and the rib plate 4 are all welded with the semi-ring substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com