Telescoping tube water sealing clamper of water drain

A sewer and telescopic pipe technology, applied in the field of sanitary ware drainage pipe fittings, achieves the effects of simple, convenient and flexible construction, convenient high and low positions, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

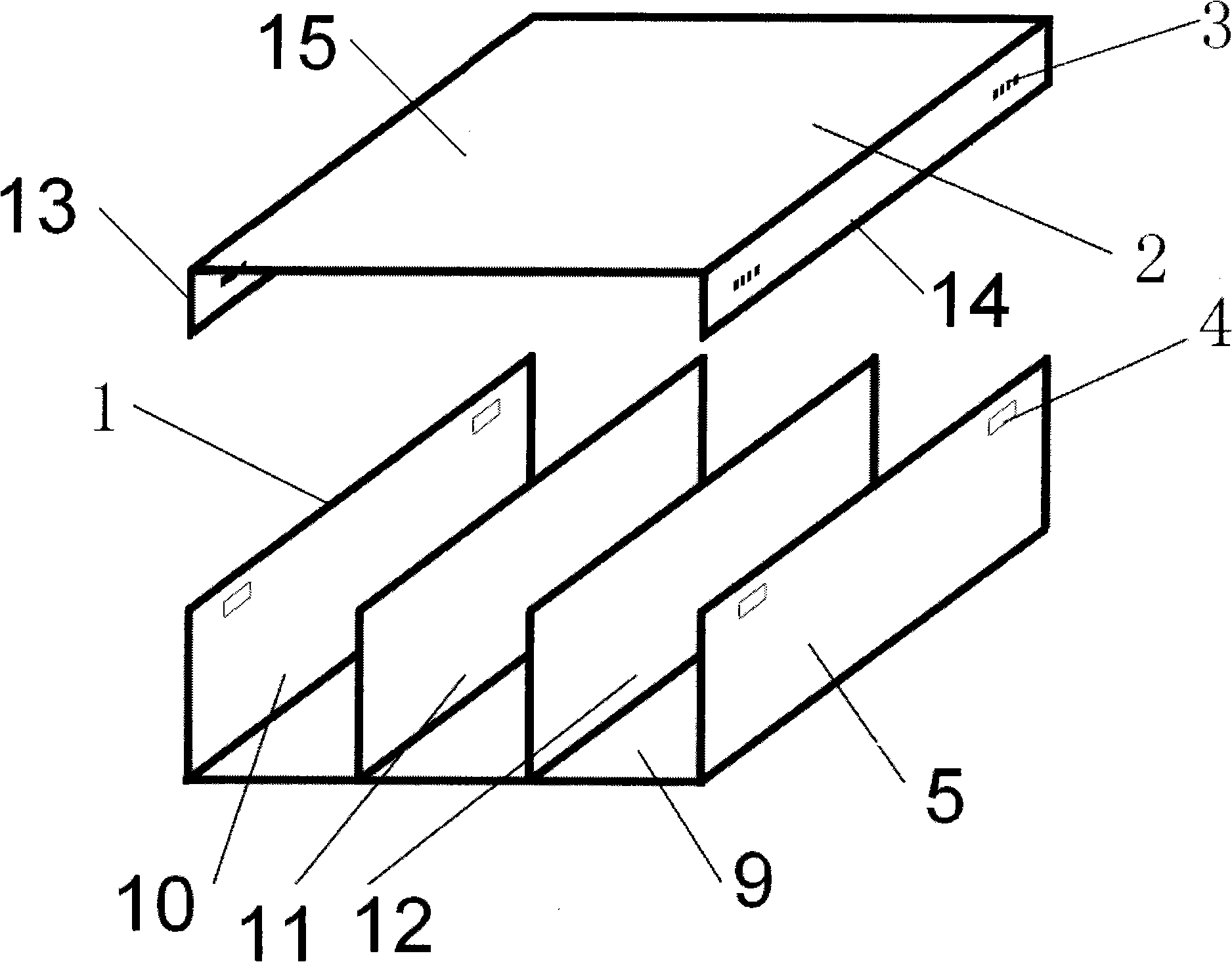

[0013] Such as figure 1 The schematic diagram of the water sealing fixture for the telescopic pipe of the sewer is composed of a fixture plate 1, a fixture cover 2, a fixture cover fixing convex column 3, a fixture cover fixing groove 4 and a telescopic pipe winding channel. The clamp tray 1 consists of a flat plate 9 and clamp tray side plates 5, 10 connected to both sides of the flat plate 9, and partitions 11, 12 placed in parallel with the clamp tray side plates 5, 10 and placed between the two clamp tray side plates 5, 10. Structure, the partition has two plates whose lower ends are fixed on the plane of the plate 9, or the plate 9, the fixture plate side plates 5, 10, and the partition plates 11, 12 whose lower ends are fixed on the plane of the plate 9 above, are manufactured into an integrated structure through a mold; There are clamp cover fixing grooves 4 on the outside of the side plates 5, 10. The clamp cover 2 is composed of a flat plate 15 and clamp cover side plate...

Embodiment 2

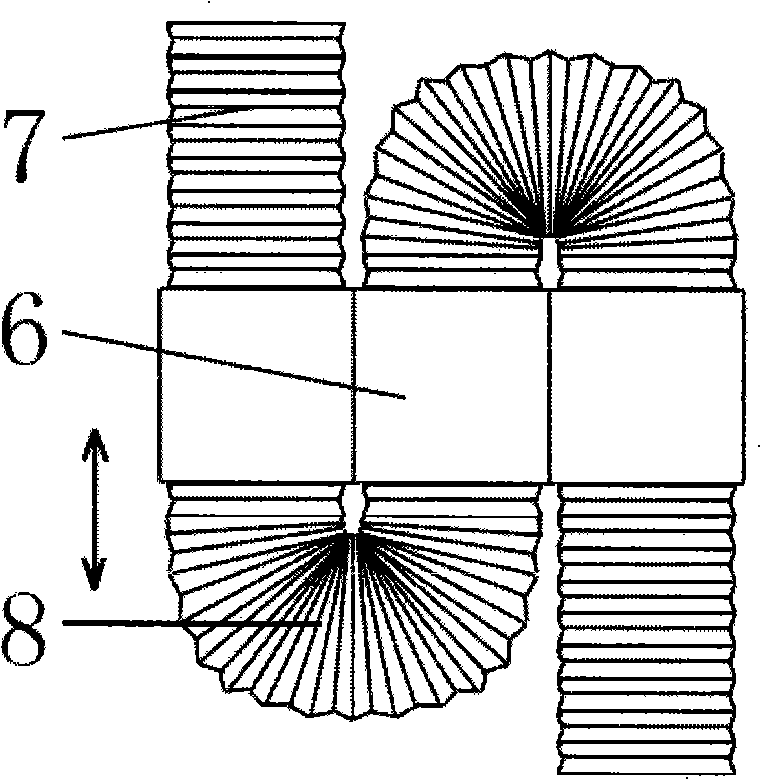

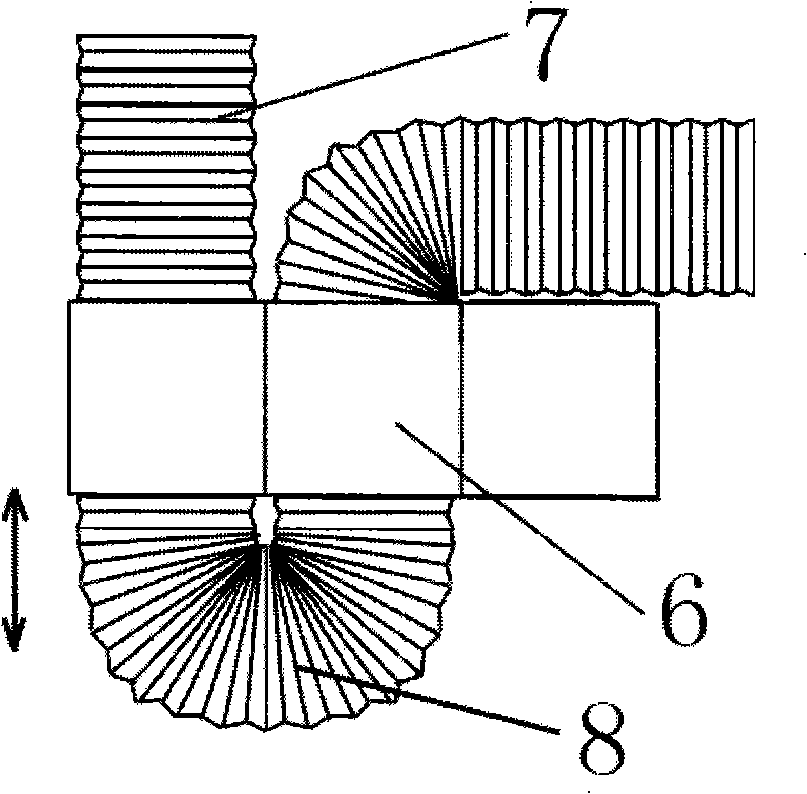

[0018] in figure 2 , image 3 In the middle, adjust the telescopic tube in the direction of the arrow to adjust the depth of the water seal of the "water seal bend" 8 to suit the different requirements for the depth of the water seal under different occasions.

Embodiment 3

[0020] When figure 2 , image 3 When the "water seal bend" 8 is blocked, open the clamp cover 2, take the telescopic tube 7 out of the clamp plate 1, and straighten the telescopic tube 7 to remove the "S" shape or " The U"-shaped water seal structure, because the telescopic tube is restored to a straight-through state, it is convenient and easy to unblock the blocked position. After the dredging is completed, according to Example 1, an "S"-shaped or "U"-shaped water seal structure is formed on the telescopic tube again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com