Manipulator, transmission mechanism of manipulator, circuit board with manipulator and manufacturing method thereof

A technology of transmission mechanism and manufacturing method, which is applied in the direction of manipulators, electrical components, electrical components, etc., and can solve the problems of limited functional rotation angle, difficulty in use, limited rotation angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

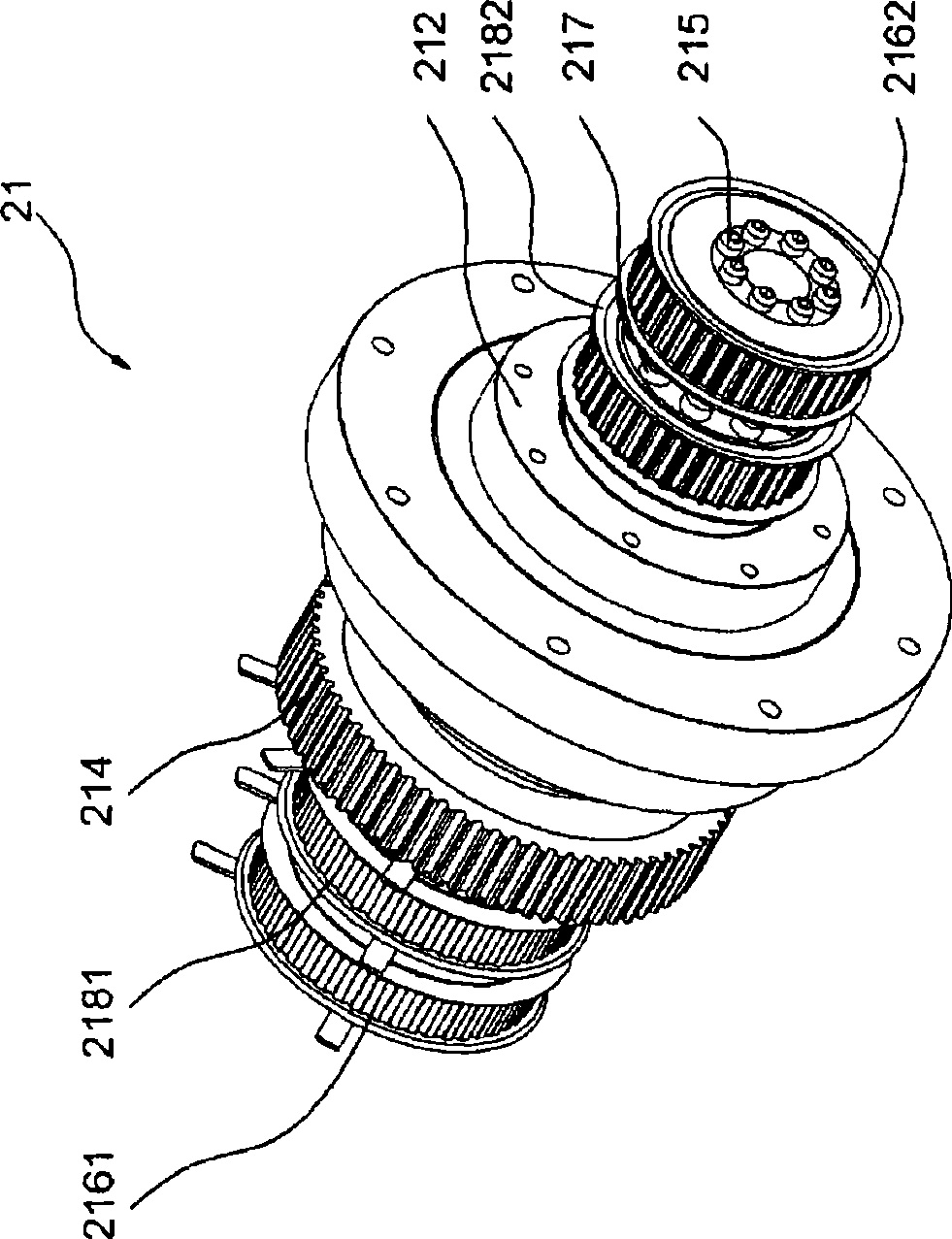

[0104] The present invention discloses a transmission mechanism used in a manipulator and a circuit board retractor with a manipulator. The transmission principle of the mechanism used has been understood by those with ordinary knowledge in the relevant technical field, so the following description will not be repeated. full description. At the same time, the accompanying drawings in the following text are schematic structural representations related to the features of the present invention, and are not and need not be completely drawn based on actual dimensions, and are described in advance.

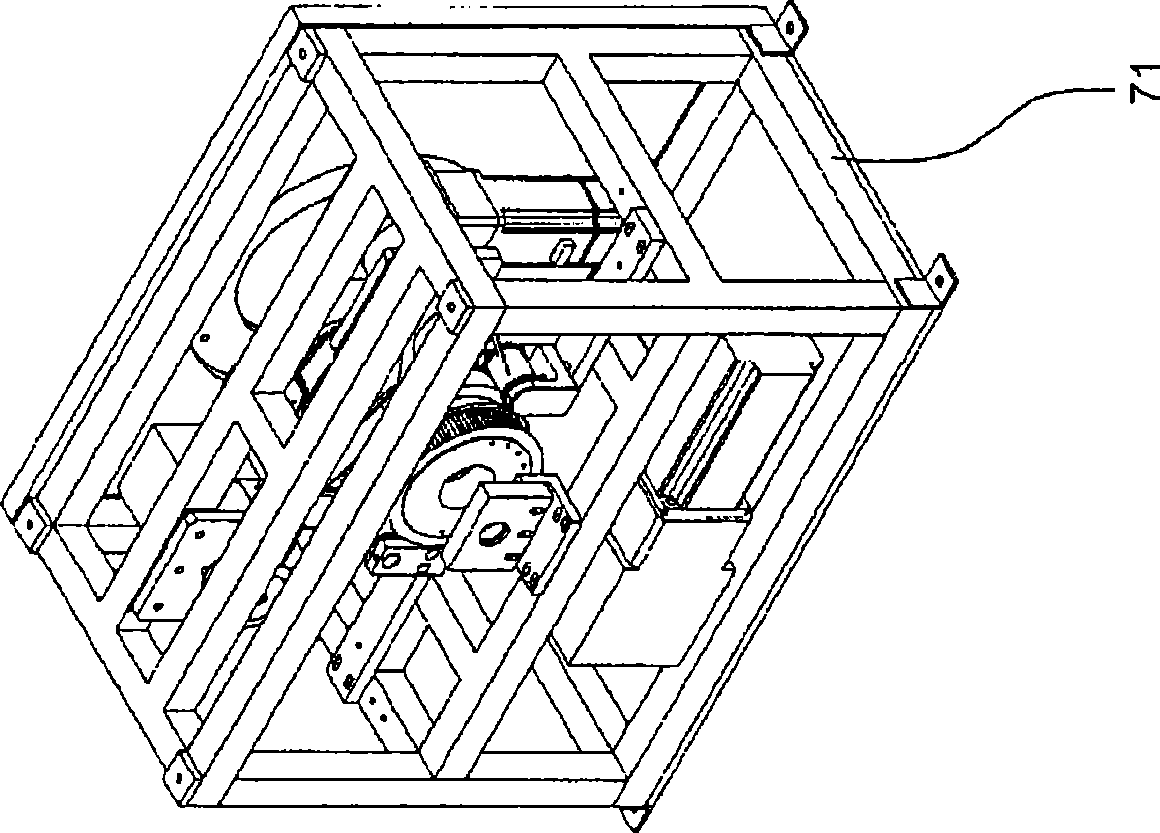

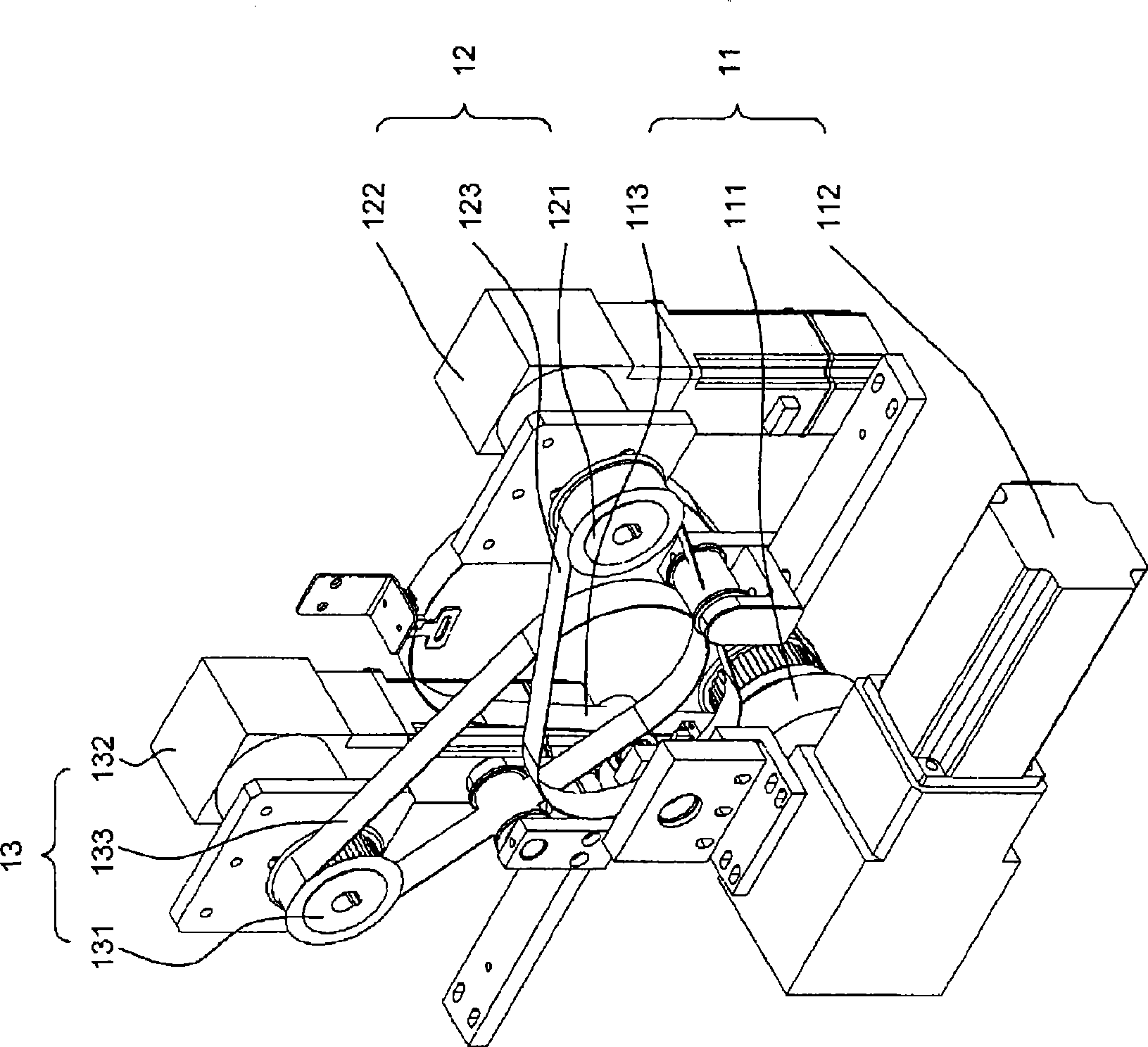

[0105] First please refer to Figure 1A to Figure 3 , according to the first preferred embodiment provided by the present invention, is a manipulator 1, mainly including a frame 71, a first shaft arm 31, a second shaft arm 32, a third shaft arm 33, a first power unit 11. The second power unit 12 and the third power unit 13 . One end of the first shaft arm 31 is connected to the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com