Tray automatic seedling-feeding device

A technology for plug tray and seedling supply, applied in the field of automatic seedling supply device, can solve the problems of low work efficiency, high labor intensity, time-consuming and laborious, etc., and achieve the effect of good grafting effect and developed root system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

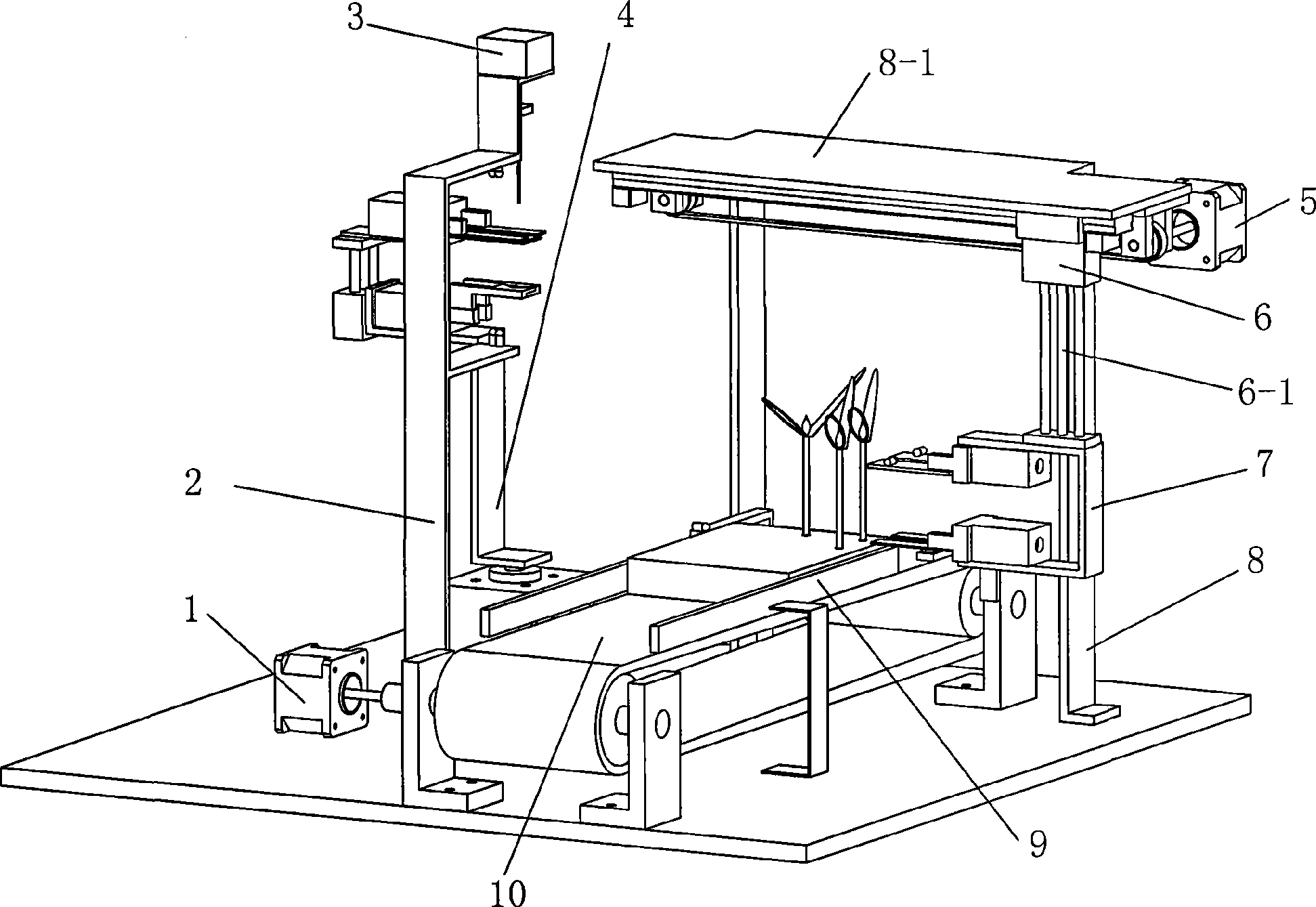

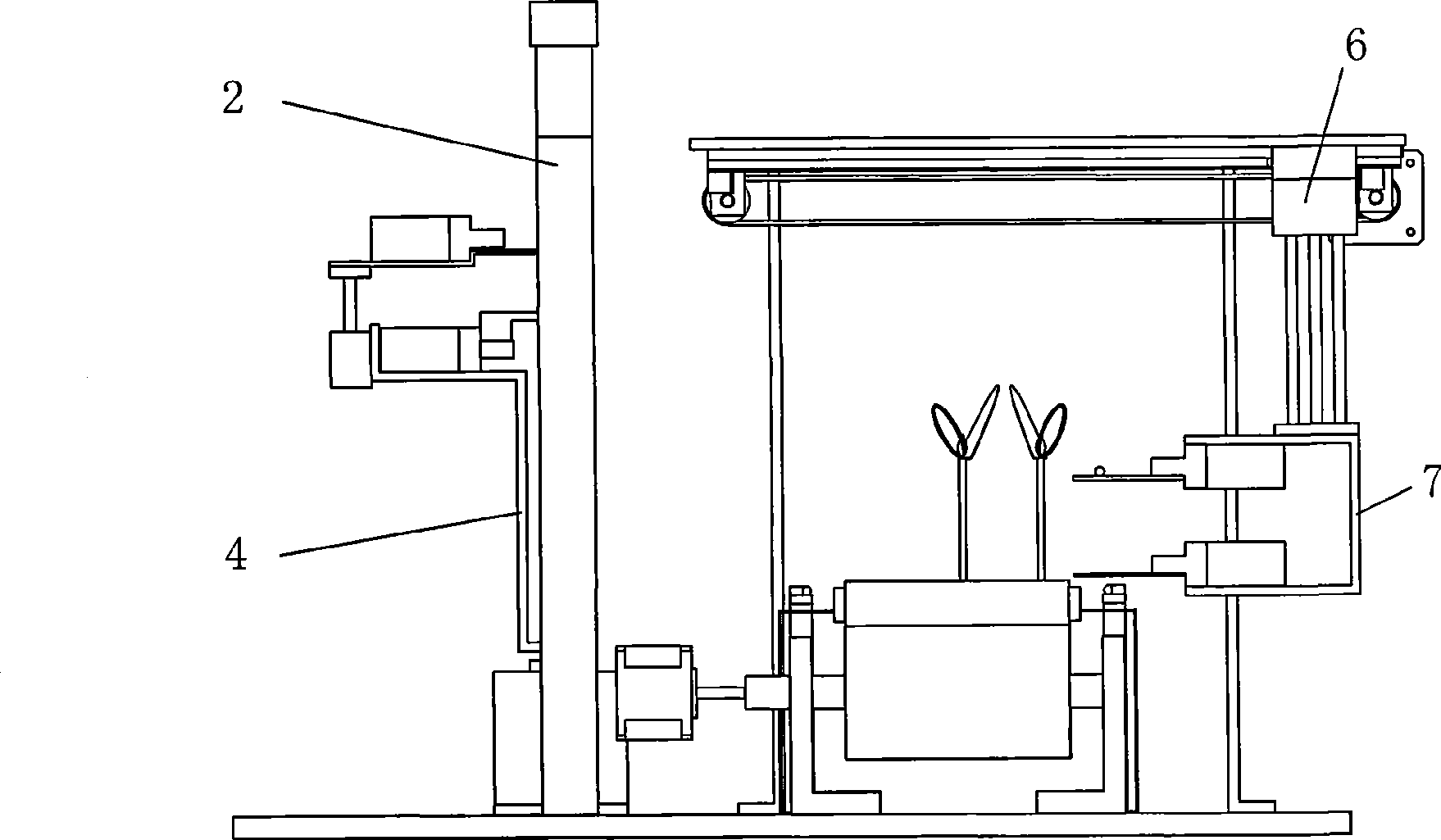

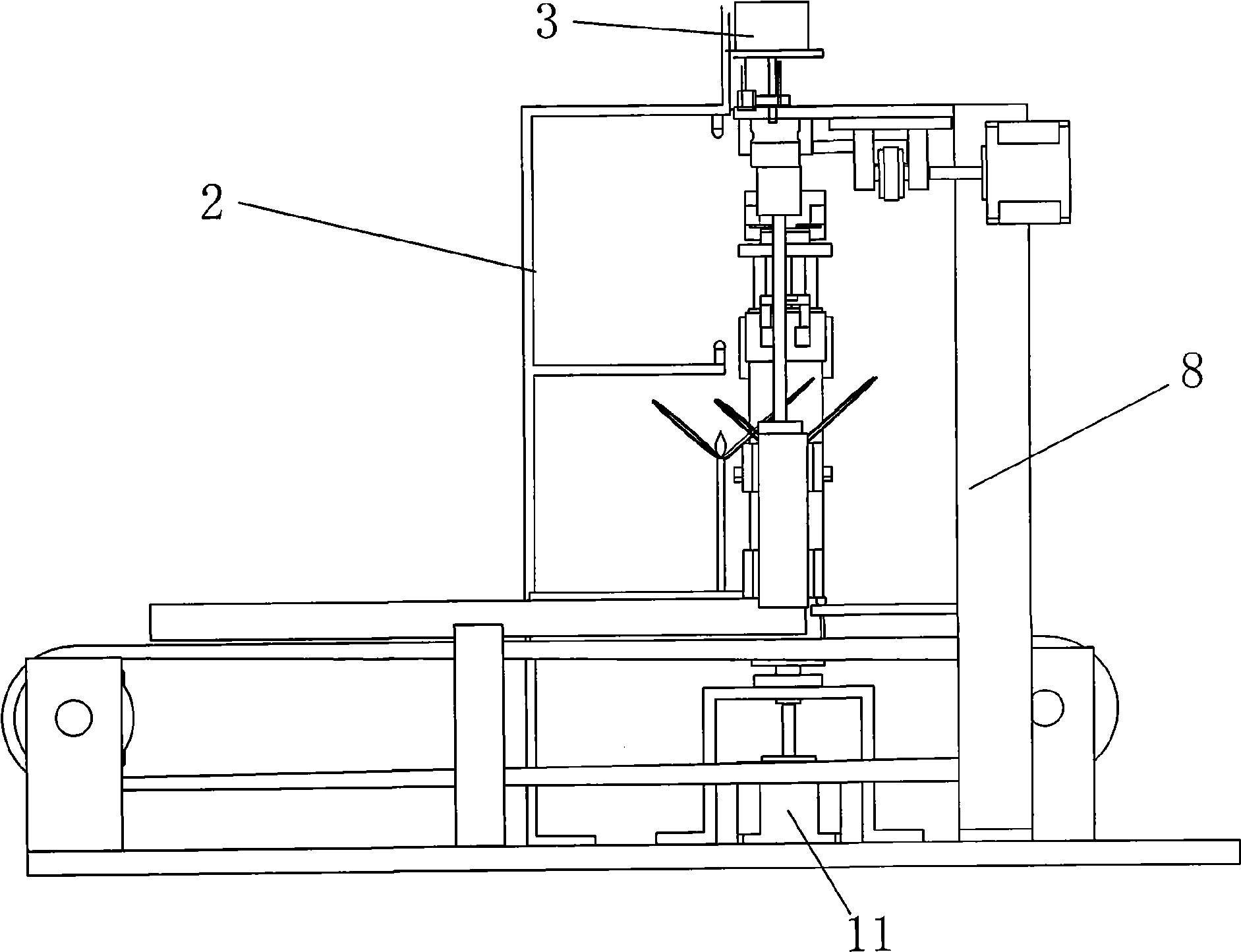

[0034] The tray automatic seedling supplying device includes a mounting plate (or machine base), on which a tray transport unit, a seedling handling unit, a seedling processing unit, and a control unit are fixed on the mounting plate.

[0035] In the tray transport unit, the conveyor belt 10 is positioned on the mounting plate by the pulley (the pulley is installed and positioned by the pulley shaft equipped with bearings), and the first stepping motor 1 drives the conveyor belt by driving the coaxially installed pulley. Movement: a pair of tray sensors 12-1 and 12-2 for determining the position of the tray are positioned on both sides of the conveyor belt, and transmit monitoring signals (usually infrared monitoring signals) horizontally. Figure 4 It can be seen from the figure that two tray sensors are installed on two mounting boards 40 . In addition, the two baffles 9 are respectively installed on both sides of the conveyor belt through brackets 9-1 to ensure that the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com