Measuring method and measuring apparatus for depth or end-face clearance of mechanical product cavity

A technology for end face clearance and mechanical products, applied in the field of a detection device for mechanical products, can solve the problems of inability to actually measure extreme values, low detection efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

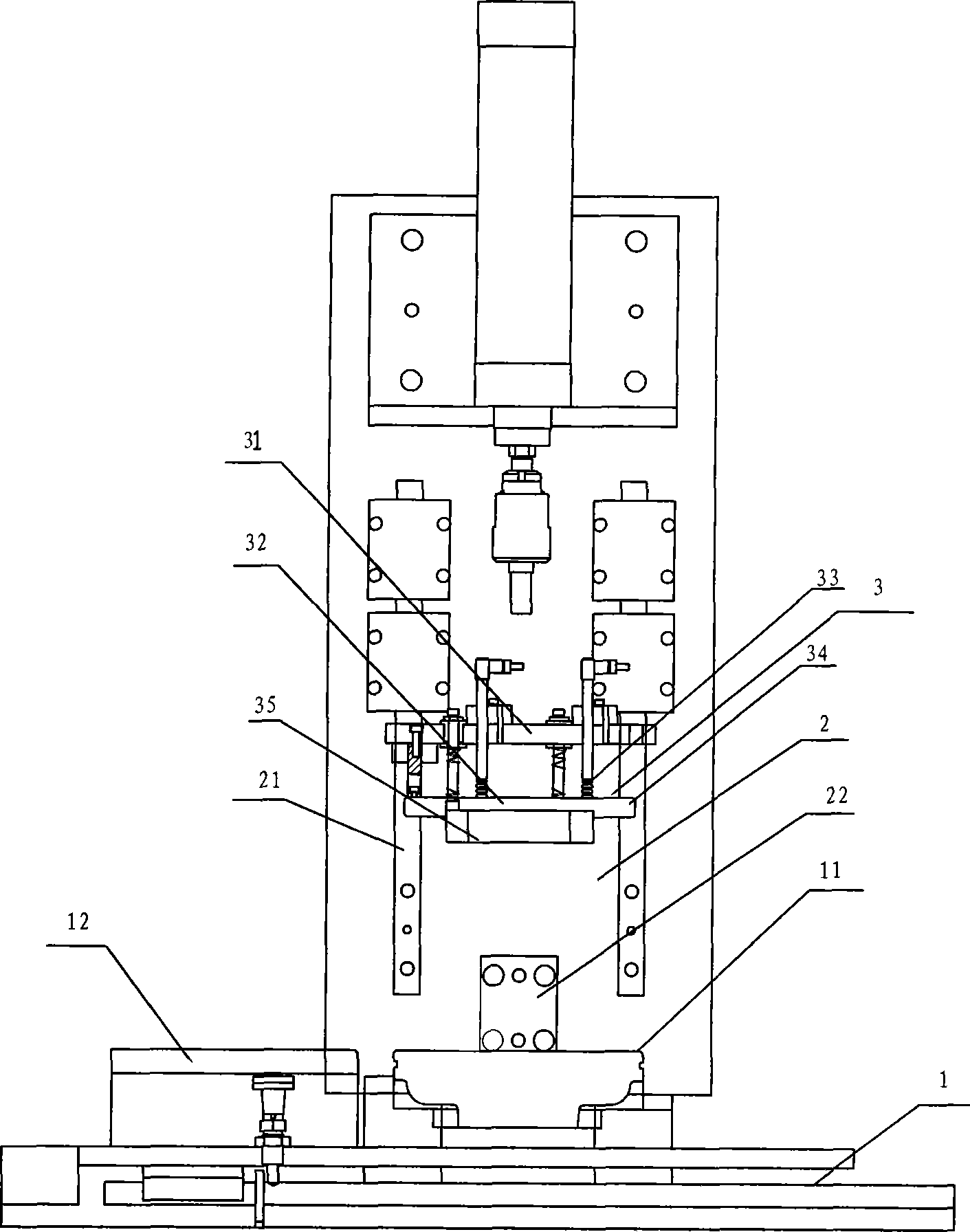

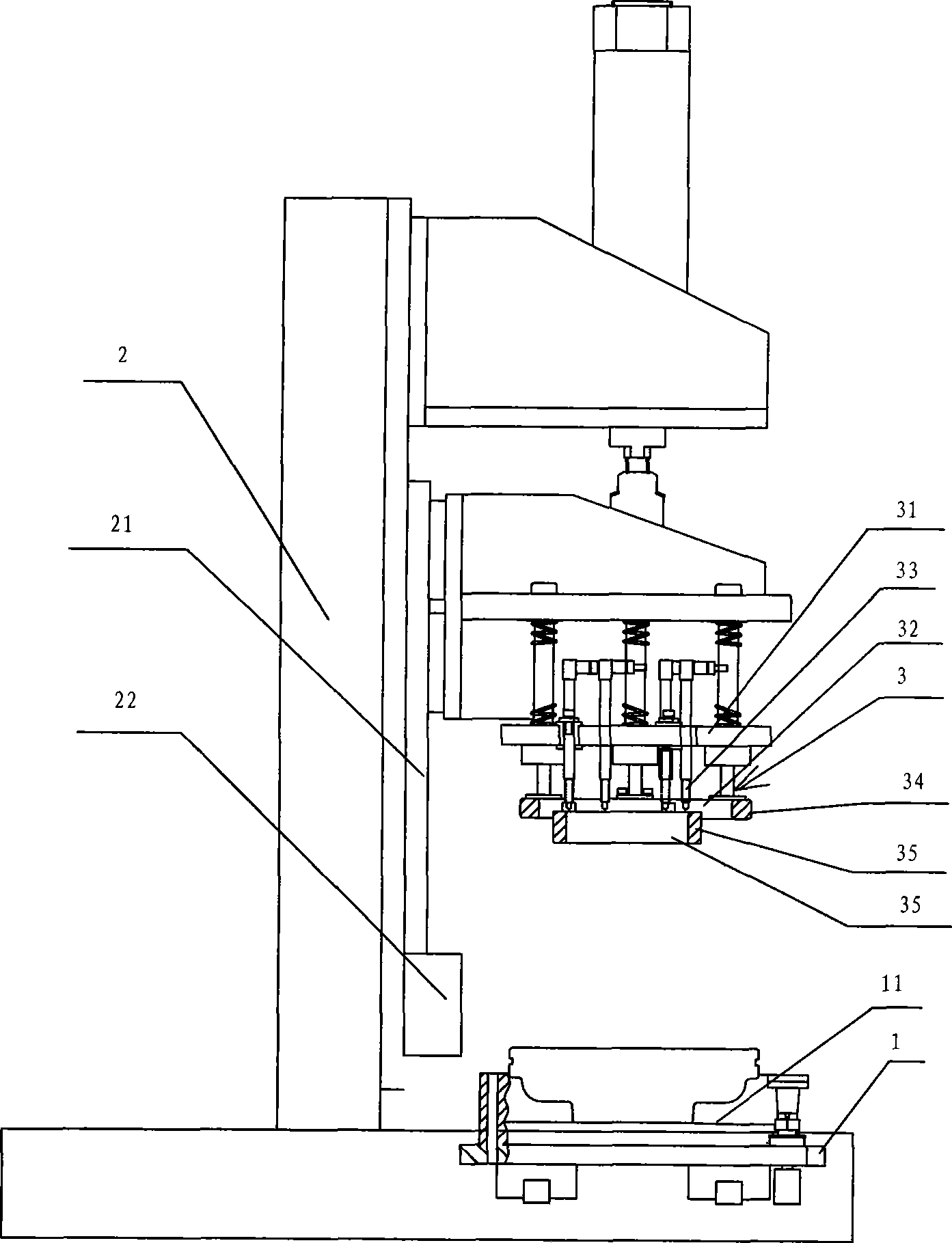

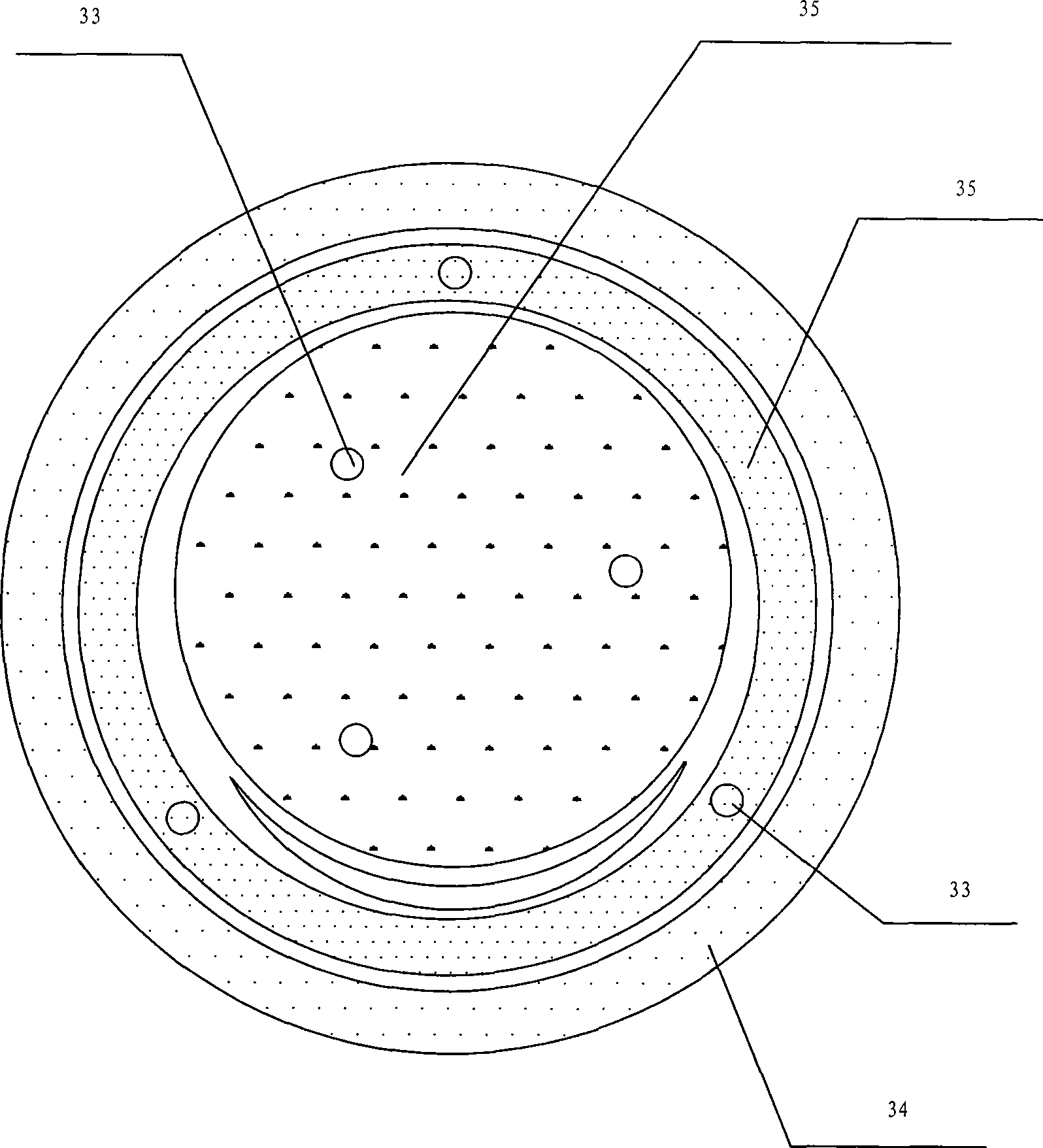

[0032] The method for measuring the depth of the mechanical product cavity or the end face gap and the measuring device used in the method of the present invention will be further described in conjunction with the accompanying drawings and specific embodiments:

[0033] A method for measuring the cavity depth or end face clearance of a mechanical product, the steps of which are as follows:

[0034] 1. First, fix the product to be measured on the workbench; the fixture seat of the product to be tested is installed on the workbench.

[0035] 2. Determine a reference plane for comparison on the product under test; that is, select an end plane for comparison on the product under test, which should be on the same side as the bottom surface or end surface of the cavity under test, mutually There is a difference between high and low.

[0036] 3. Establish a comparison reference plane with the comparison reference plane as the standard; that is, set a disc of the comparison reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com